Composite hollow slab house and building method thereof

A technology of hollow-core slabs and houses, applied in the direction of building construction, construction, etc., to achieve the effects of saving resources, light installation, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

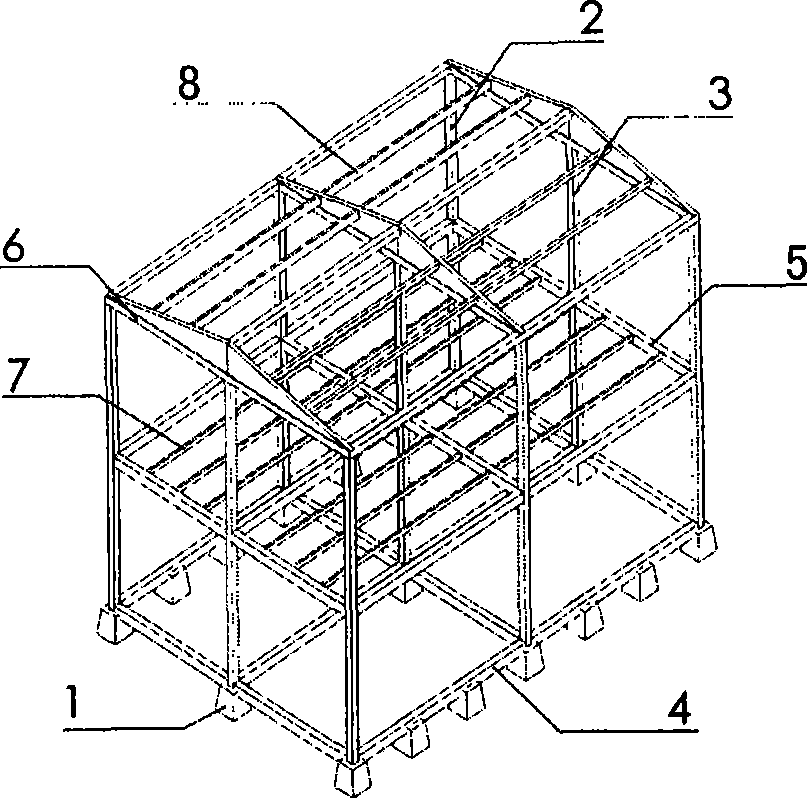

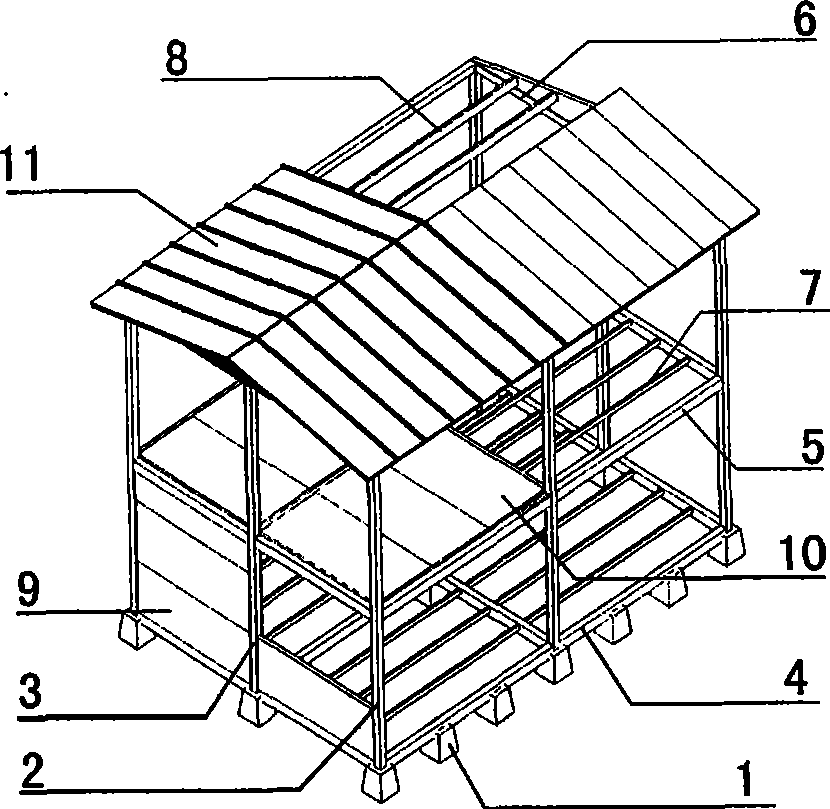

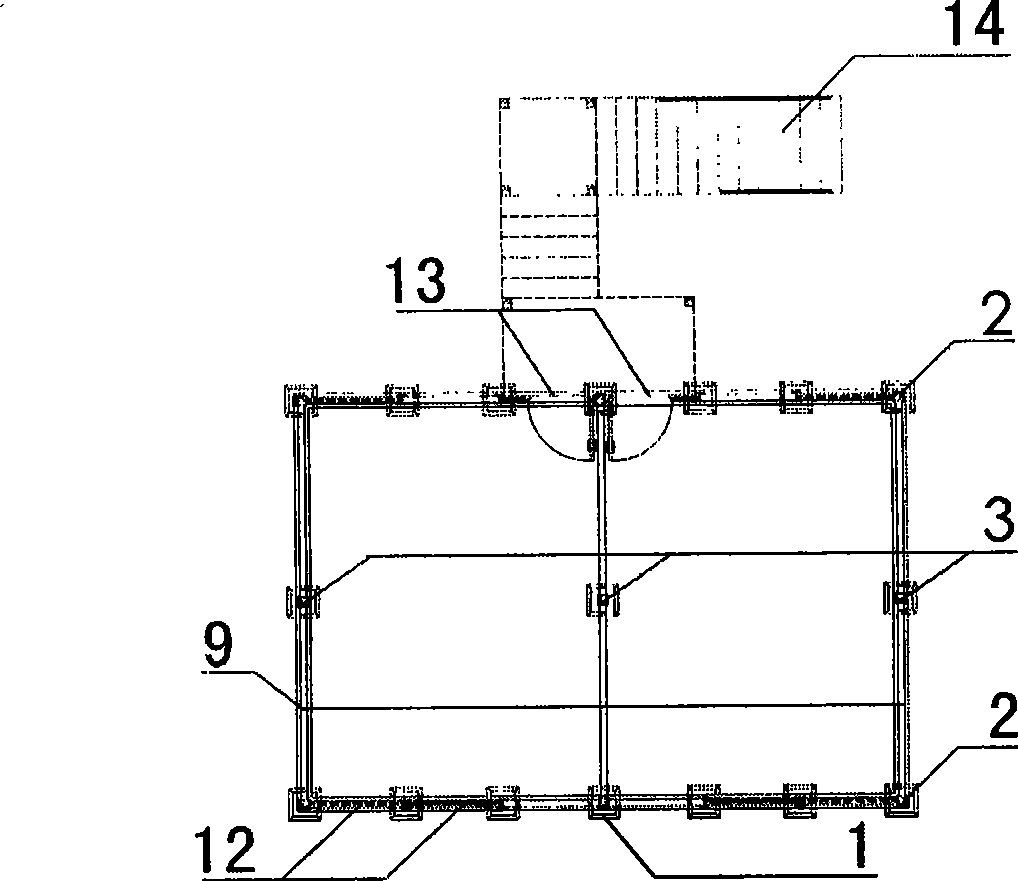

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

[0054] The test house of the present invention is designed and constructed by post-disaster resettlement houses, and has 4 standard rooms, two floors, two upper and lower rooms, each room is 20 square meters, and the total building area is 80 square meters. The test room adopts outdoor wooden stairs, without water supply and drainage facilities.

[0055] The test room uses factory-produced components. Except for doors and windows, there are only three types of components, namely columns, beams, and panels. After these three components are produced and processed in the factory, all the components will be loaded into a truck and transported to construction. The site was installed by five workers (including three carpenters and two assistant installers), and the assembly of the test room was basically completed in seven days.

[0056] The wooden test room is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com