Self-adapting flexible vane rotor

A blade rotor, self-adaptive technology, applied in climate sustainability, engines, wind turbines at right angles to the wind direction, etc., can solve the problems of high R&D and production costs, complex control processes, unfavorable promotion and application, etc., and achieve easy maintenance. , High energy conversion efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

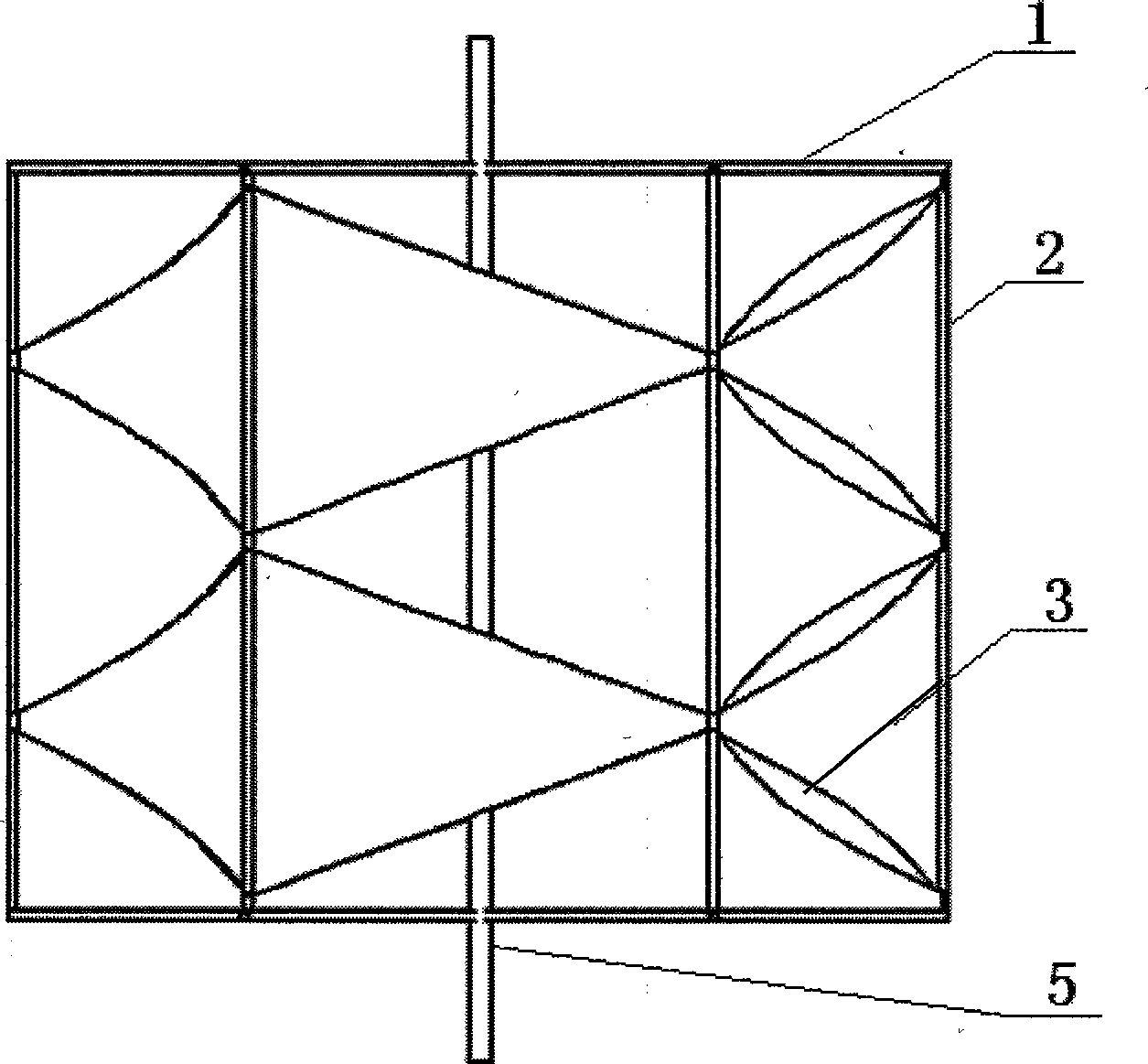

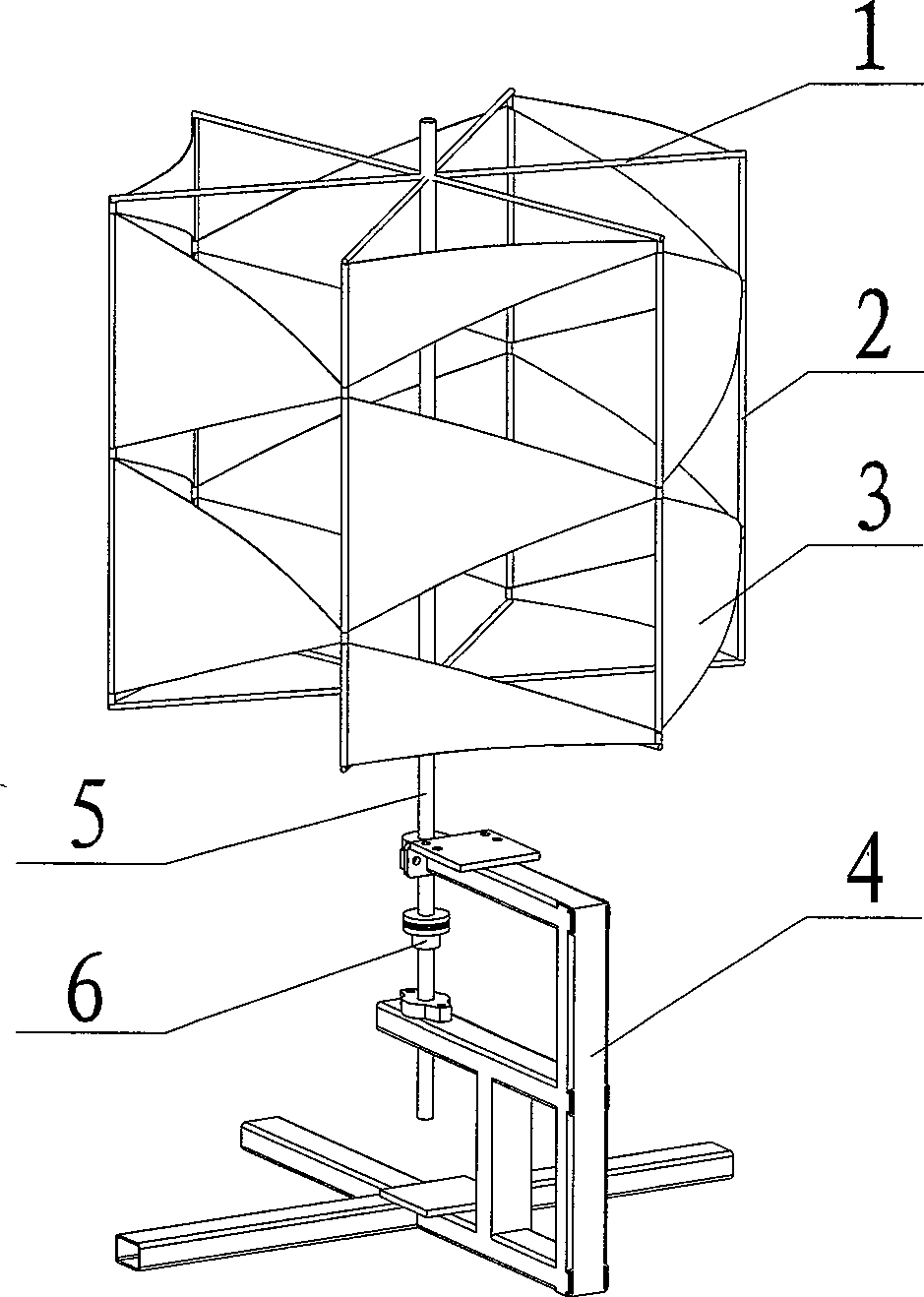

[0018] Such as figure 1 , 2 As shown, the application of the present invention in wind power generation, when the present invention is applied to wind power generation, it is called a flexible blade windmill, and the installation of the flexible blade rotor adopts a vertical axis installation method. It includes a central rotating shaft 5 , flexible blades 3 , a support layer, a fixed rod 2 , a fixed bracket 4 and an output drive wheel 6 . Two supporting layers perpendicular to the central rotating shaft 5 are arranged on the central rotating shaft 5, and the supporting layer adopts supporting rods 1 perpendicular to the central rotating shaft 5 and centered on the central rotating shaft 5 with the same interval angle and radially equal in length. The fixed rods 2 are arranged at intervals on the same circumference centered on the central rotating shaft 5 between the two support layers, the flexible blades 3 are arranged between the adjacent fixed rods 2, and the output drive...

Embodiment 2

[0021] The difference from Embodiment 1 is that: the central rotating shaft 5 is provided with three upper and lower support layers perpendicular to the central rotating shaft 5 . The supporting layer adopts support rods 1 perpendicular to the central rotating shaft 5 and centering on the central rotating shaft 5 to be radially equal in length at the same interval angle, and is arranged at intervals on the same circle centered on the central rotating shaft 5 between two adjacent supporting layers The fixed rods 2, the flexible blades 3 are arranged between the adjacent fixed rods 2. The flexible blades 3 are arranged in an equilateral triangle and an isosceles trapezoid at intervals, and the direction in which the flexible blades 3 of the equilateral triangle and isosceles trapezoid are arranged is consistent with the central rotating shaft 5 .

Embodiment 3

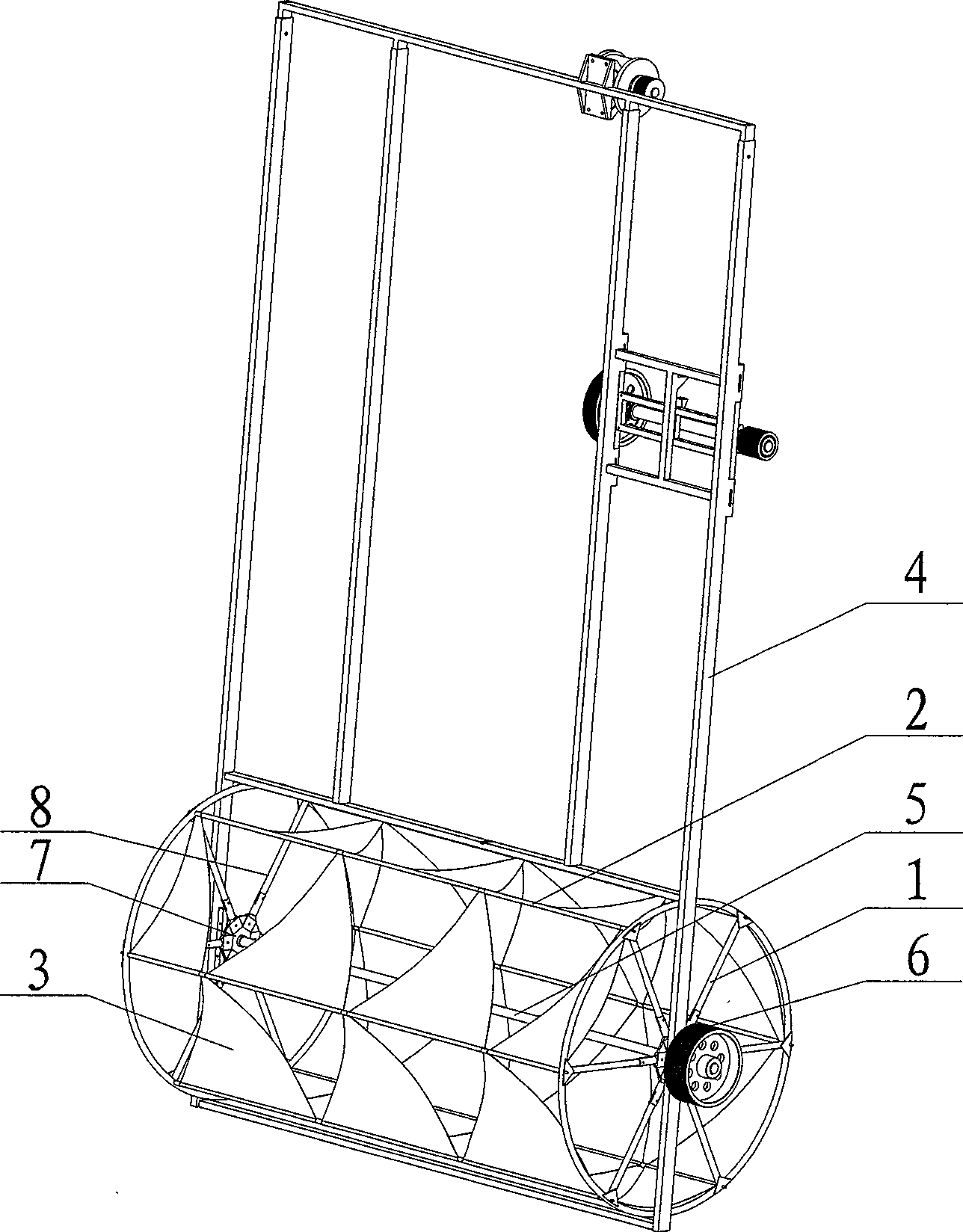

[0023] Such as image 3 As shown, the application of the present invention in hydropower generation, when the present invention is applied to hydropower generation, it is called a flexible blade water turbine, and the flexible blade rotor adopts a horizontal axis installation method. It includes a central rotating shaft 5, a flange 7, a fixed rod 2, a flexible blade 3, a fixed bracket 4 and an output drive wheel 6. On the central rotating shaft 5, two supporting layers perpendicular to the central rotating shaft 5 are arranged on the left and right. Between the two supporting layers The fixed rods 2 are arranged at intervals on the same circumference centered on the central rotating shaft 3, and the flexible blades 3 are arranged between adjacent fixed rods 2, and have a certain degree of slack. The plane formed by 2 can produce concave-convex deformation, the output driving wheel 6 is connected with the central rotating shaft 3 through a key, and the whole device is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com