Light emitting diode

A technology of light-emitting diodes and electrodes, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of reduced efficiency of phosphor powder 132, reduced light output efficiency and uniformity of light-emitting diodes 10, and achieves good uniformity and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

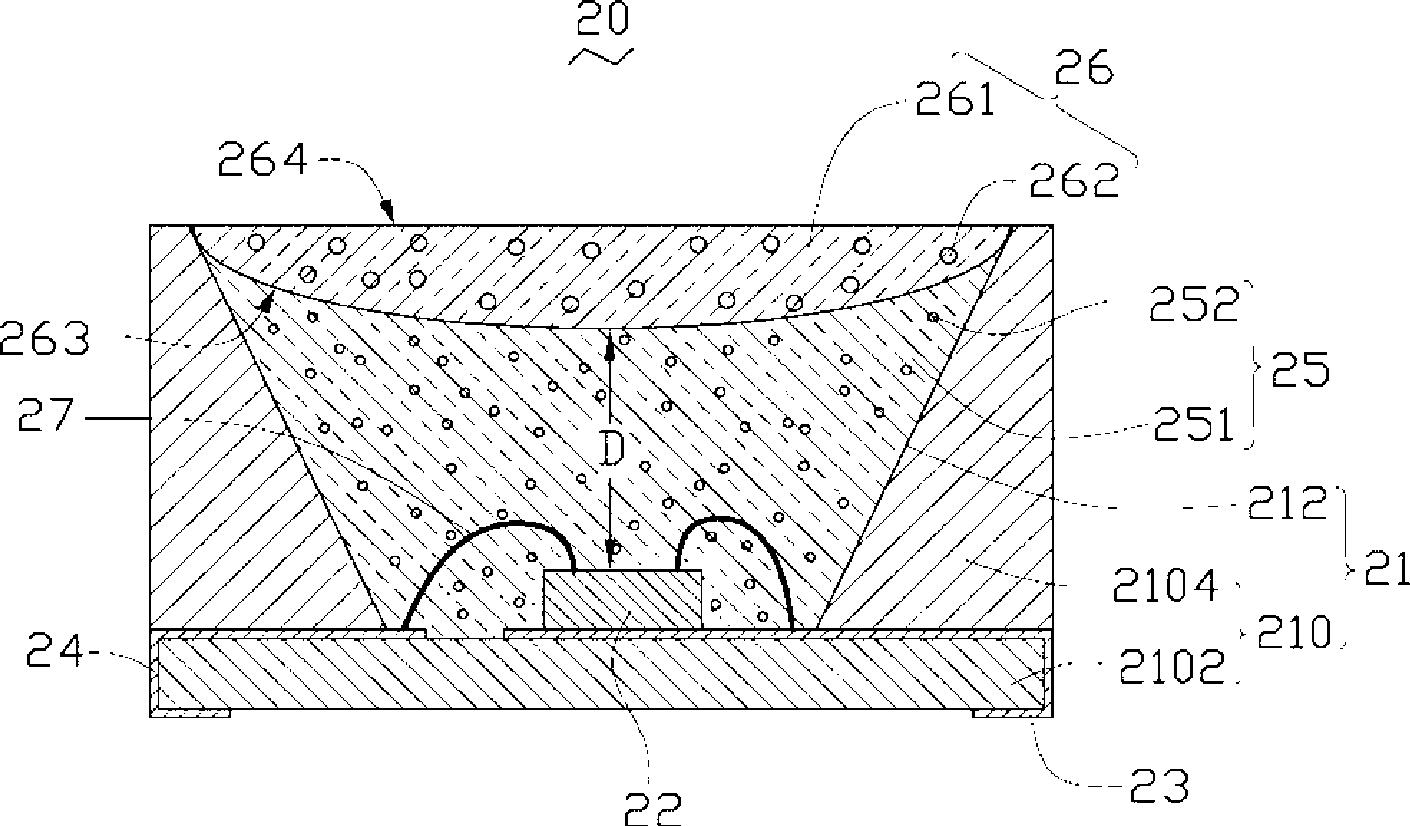

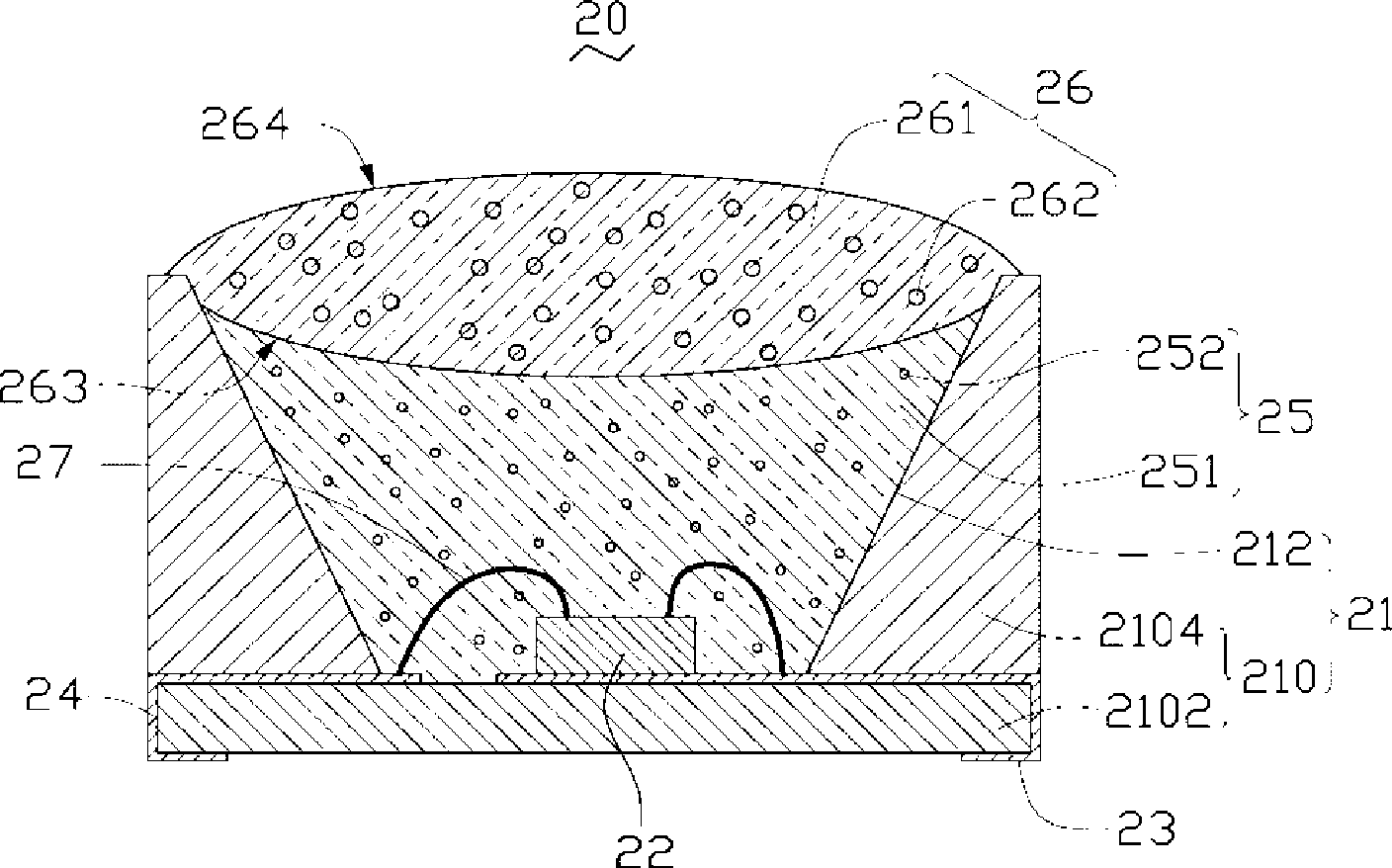

[0013] See figure 2 , the light emitting diode 20 provided by the first embodiment of the present invention comprises a reflective cup 21, a light emitting diode chip 22, a first electrode 23, a second electrode 24, a first scattering layer 25 and a light conversion layer 26 .

[0014] The reflector 21 includes a body 210 and a receiving groove 212 disposed on the body 210 . The body 210 includes a base 2102 and an annular sidewall 2104 disposed on the base 2102 . The accommodating groove 212 is surrounded by the base 2102 and the annular sidewall 2104 . The inner surface of the annular sidewall 2104 is used to reflect light. The accommodating groove 212 is tapered, and its opening gradually becomes larger along a direction away from the LED chip 22 .

[0015] The first electrode 23 and the second electrode 24 are disposed on the base 2102 and respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com