Unwinding assisting device and automatic winder comprising the same

An auxiliary device and winder technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of complicated electrical wiring arrangement of stepping motors, easy loosening, impact, etc., to achieve The effect of shortening the cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

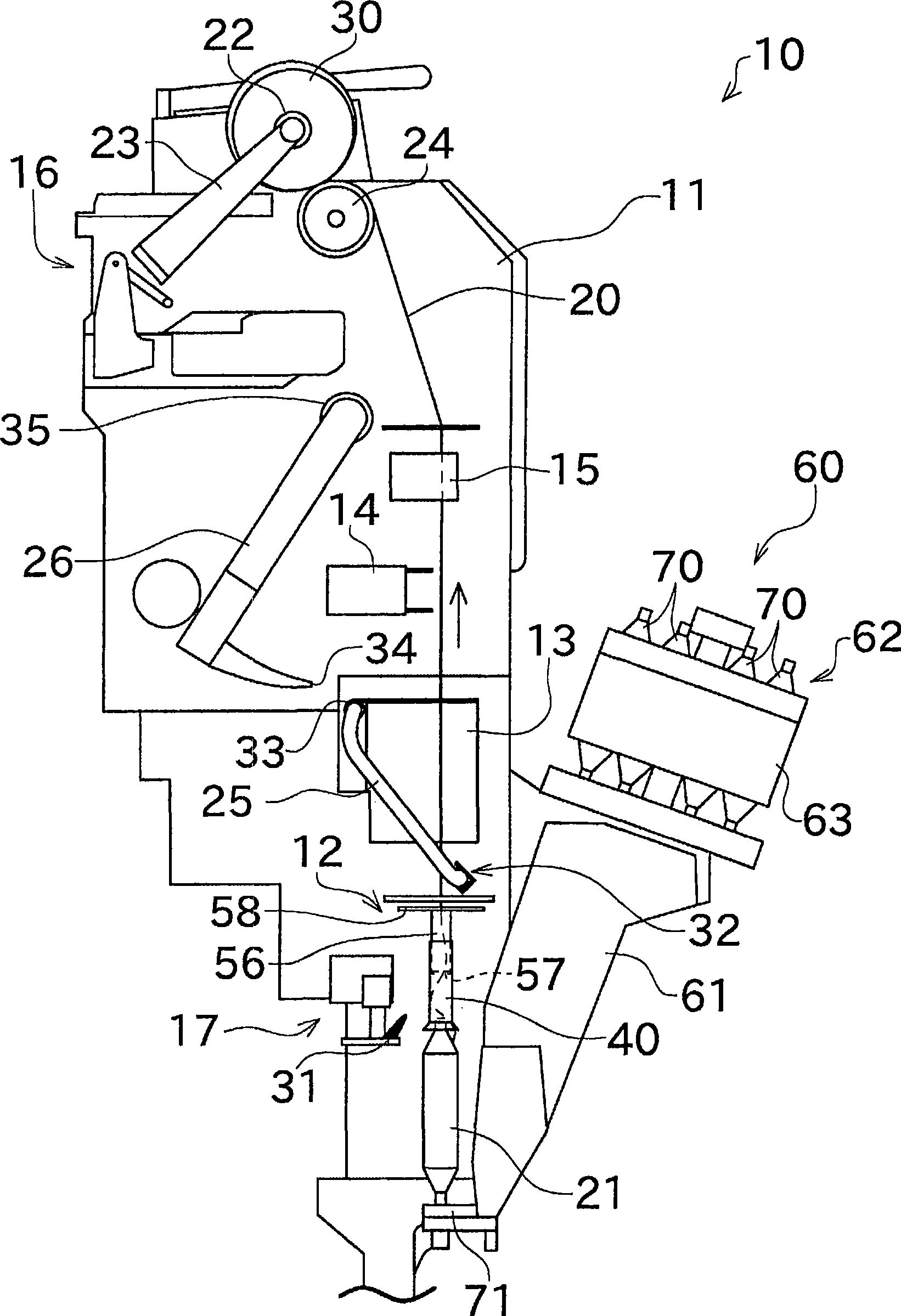

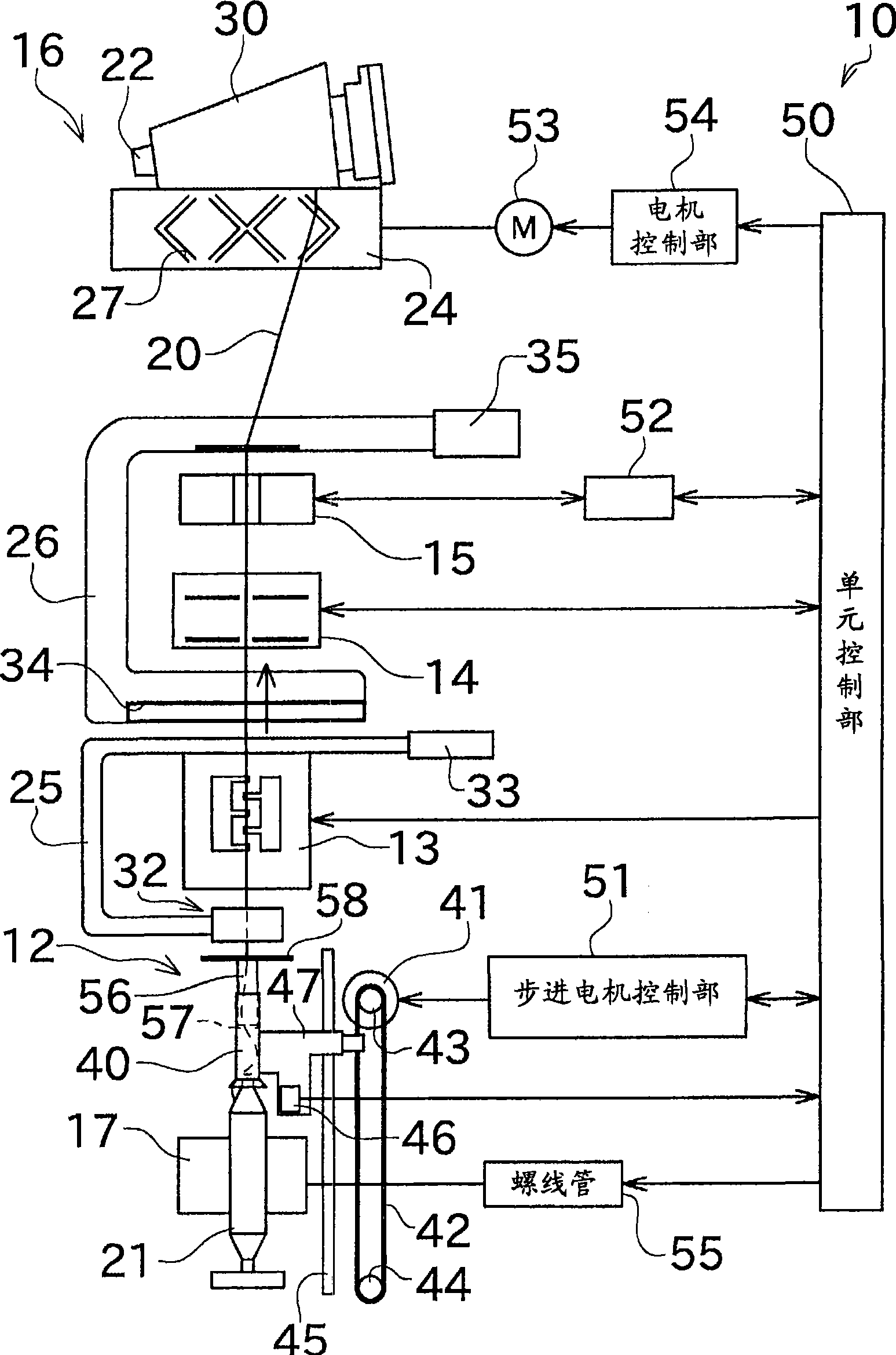

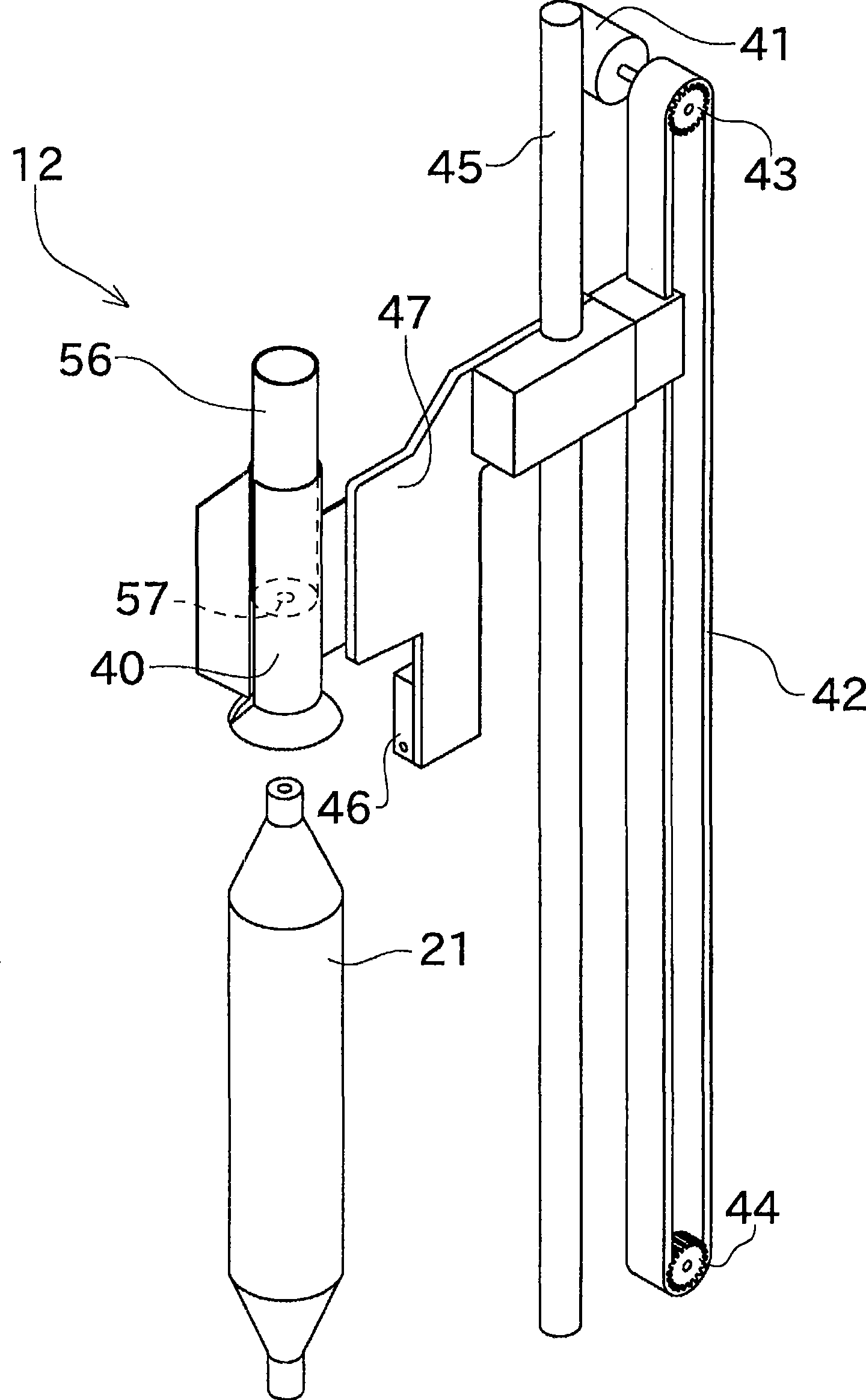

[0023] Next, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a side view of the winder unit 10 included in the automatic winder according to one embodiment of the present invention. figure 2 It is a front view schematically showing the structure of the winder unit 10 .

[0024] figure 1 with figure 2 The winder unit 10 shown is a device that traverses the yarn 20 unwound from the yarn supplying bobbin 21 on the winding bobbin 22 to form a package 30 of a predetermined shape with a predetermined length. The automatic winder of this embodiment includes a plurality of winder units 10 arranged in parallel, and a machine control device (not shown) arranged at one end in the parallel direction.

[0025] Each winder unit 10 has a unit frame 11 ( figure 1 ) and the winding unit main body 16 arranged on the side of the unit frame 11.

[0026] The winding unit main body 16 has a cradle 23 capable of holding the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com