Large energy accumulation type air source heat pump hot water units

A technology of air source heat pump and hot water unit, applied in heat pump, refrigerator, compressor, etc., can solve the problems of heat pump system without energy storage function and poor energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

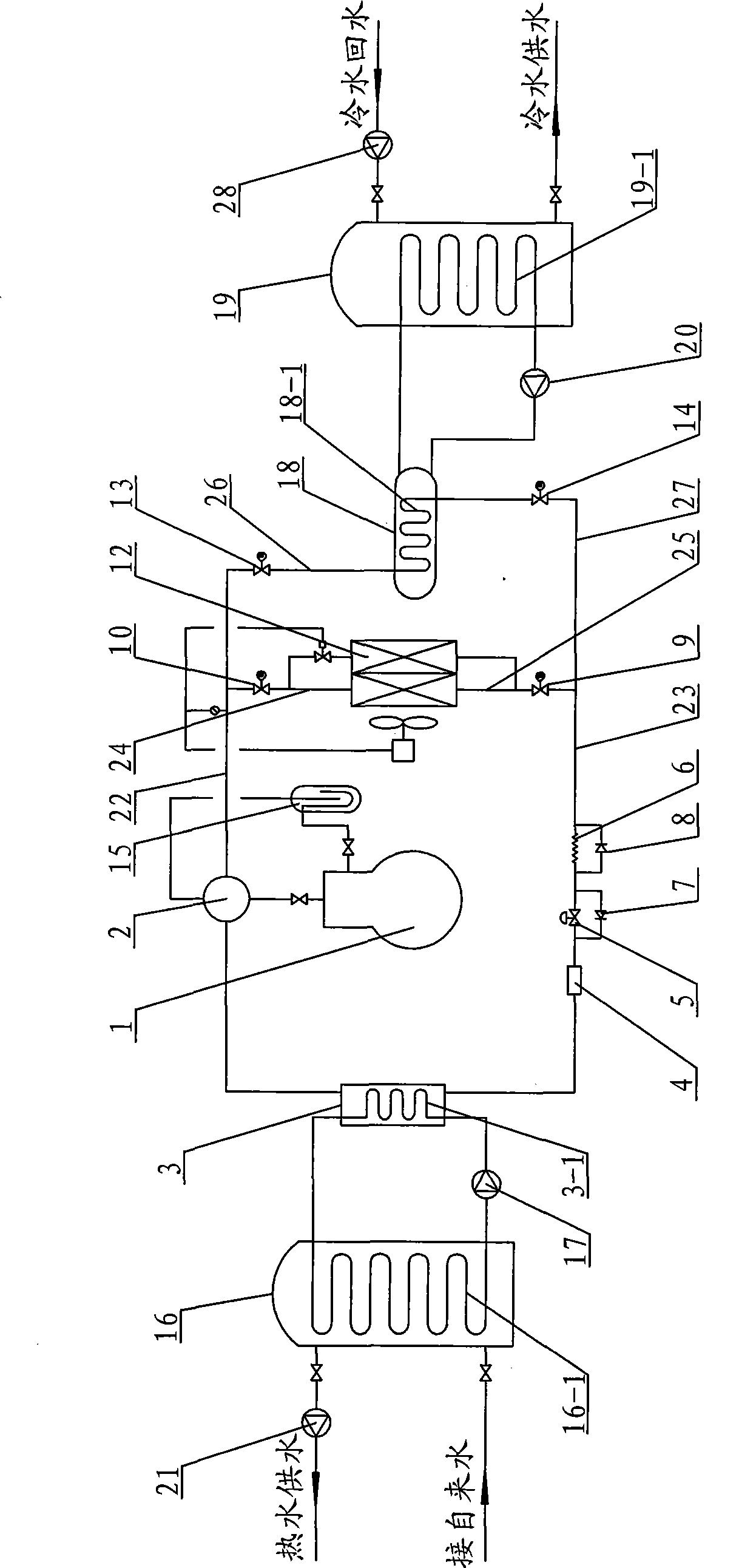

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a compressor 1, a four-way reversing valve 2, a plate heat exchanger 3, a dry filter 4, an electronic expansion valve 5, a capillary 6, a first one-way valve 7, a second one-way valve Valve 8, first solenoid valve 9, second solenoid valve 10, outdoor heat exchanger 12, gas-liquid separator 15, first connecting pipe 22, second connecting pipe 23, third connecting pipe 24, fourth connecting pipe 25, heat storage tank 16. The hot water circulation pump 17 and the hot water supply pump 21, the four valve ports of the four-way reversing valve 2 are respectively connected with the compressor 1, the plate heat exchanger 3, the gas-liquid separator 15 and the first connecting pipe 22 through pipelines One end of the outdoor heat exchanger 12 is connected to the first connecting pipe 22 through the third connecting pipe 24, the other end of the outdoor heat exchanger 12 is conne...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: it also adds a fourth solenoid valve 13, a fifth solenoid valve 14, a shell-and-tube heat exchanger 18, a cold storage tank 19, and a cold water circulation pump 20 , the fifth connecting pipe 26, the sixth connecting pipe 27 and the cold water return pump 28, one end of the evaporation pipe 18-1 in the shell-and-tube heat exchanger 18 is connected to the first connecting pipe 22 through the fifth connecting pipe 26, and the shell-and-tube heat exchanger The other end of the evaporation pipe 18-1 in 18 is connected to the second pipeline 23 through the sixth connecting pipe 27, and the two ends of the cold water pipe 19-1 in the cold storage tank 19 are respectively connected to the shell and tube heat exchanger 18 through pipelines. , the cold water circulation pump 20 is set on the pipeline between the cold storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com