High-pressure discharge lamp with an improved starting capability, as well as a high-voltage pulse generator

A technology of high-pressure discharge lamps and pulse generators, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of being unable to be heated, and achieve the effect of easy breakdown and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

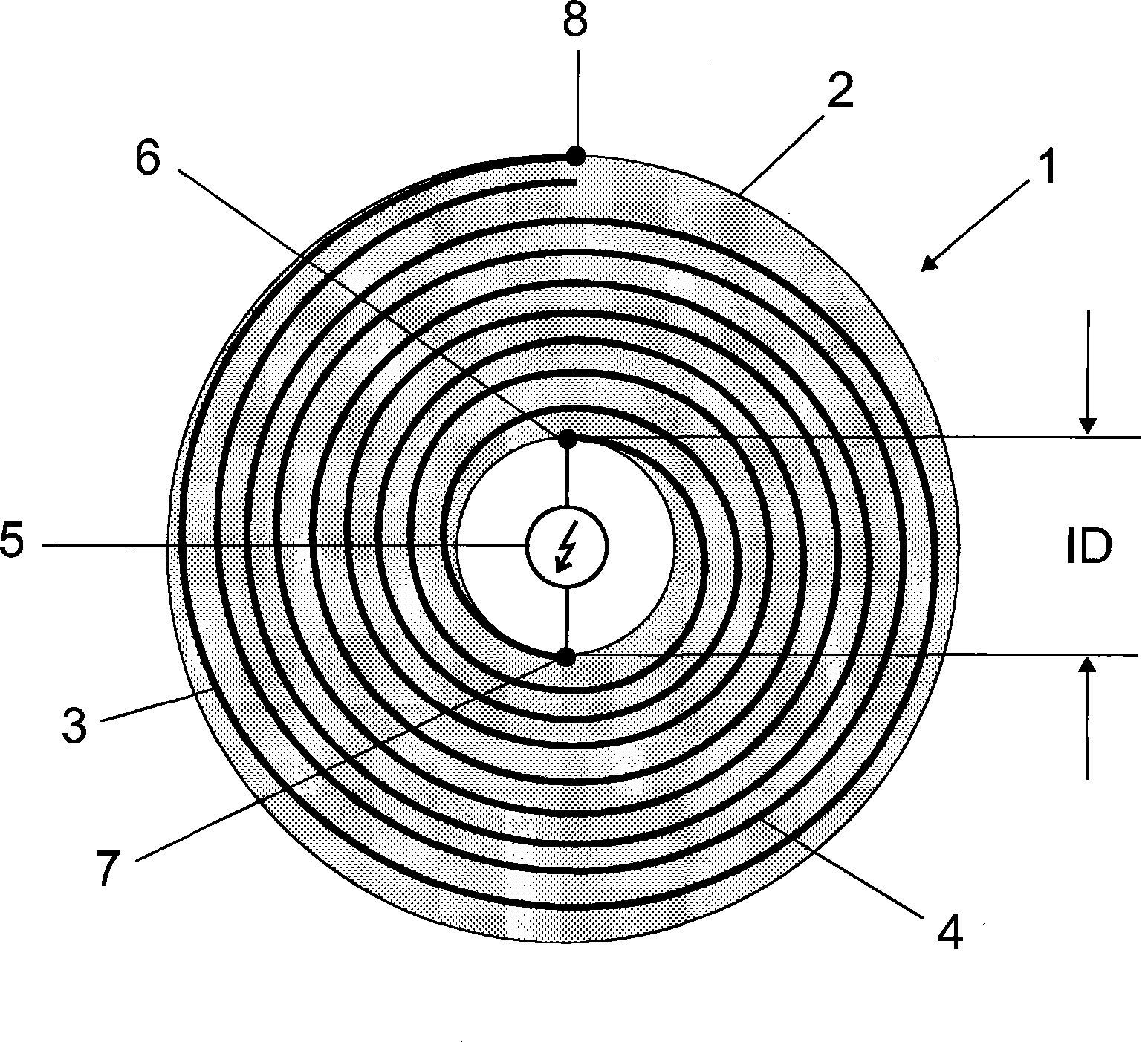

[0028] figure 1 The structure of the helical pulse generator 1 is shown in plan view. The helical pulse generator comprises a ceramic cylinder 2 into which two different metallic conductors 3 and 4 are helically wound as foil strips. The cylinder 2 is hollow inside and has a given inner diameter ID. The two inner contacts 6 and 7 of the two conductors 3 and 4 lie approximately opposite each other and are connected to each other via a spark arrestor 5 .

[0029] Only the outer conductor of the two conductors has another contact 8 at the outer edge of the cylinder. The other conductor ends open. Thus, the two conductors together form a waveguide in a dielectric medium (ceramic).

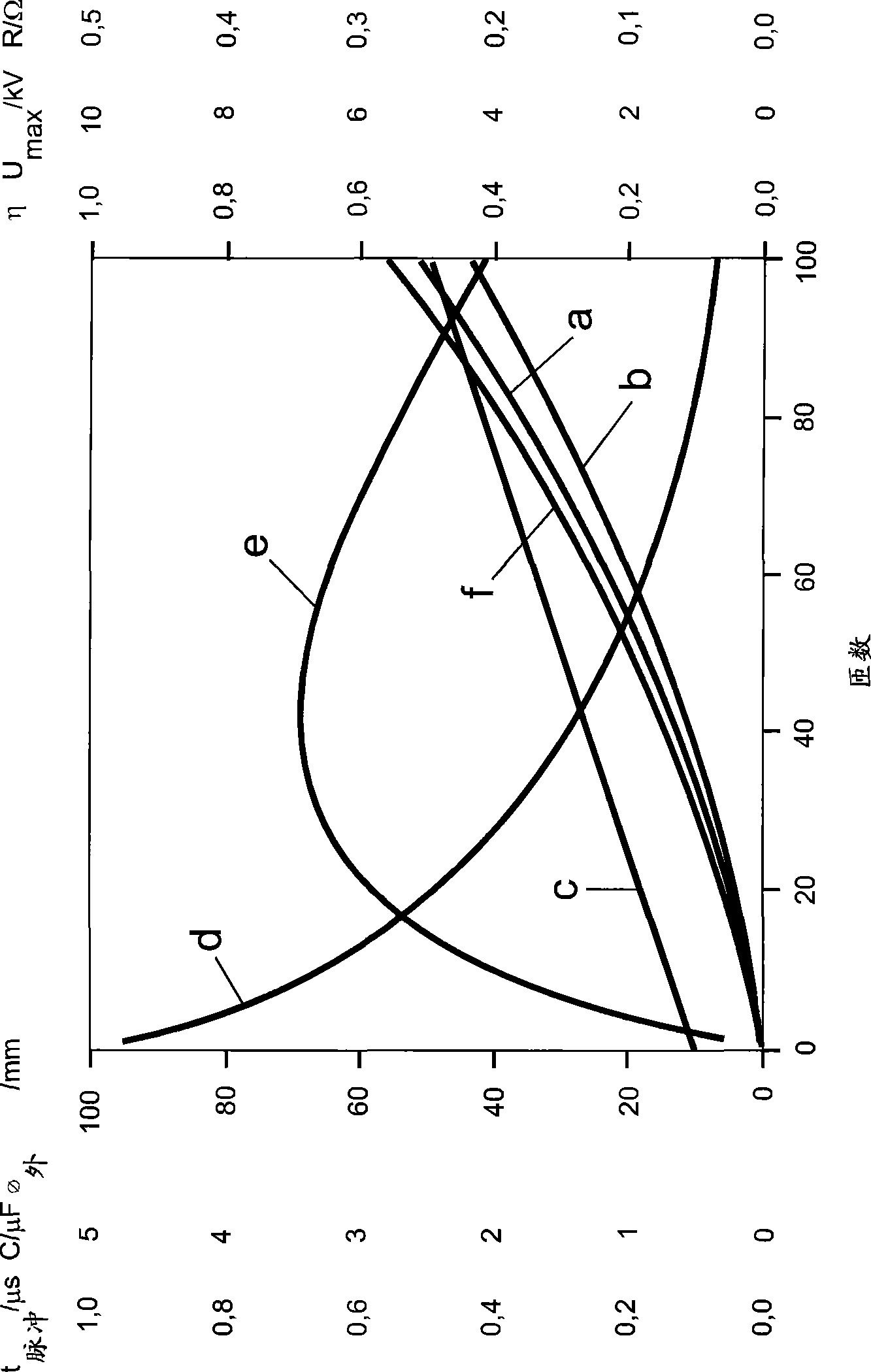

[0030] Helical pulse generators are wound from two ceramic discs coated with metal paste or constructed from two metal discs and two ceramic discs. An important characteristic parameter here is the number of turns n, which should preferably be in the order of magnitude of 5 to 100. The winding ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com