Flexible composite heat conducting material for liquid nitrogen refrigerating apparatus

A composite heat-conducting material and liquid nitrogen refrigeration technology, which is applied in the field of space low temperature, can solve the problems of reducing effective working time, difficulty in achieving refrigeration purposes, and increased loss of liquid nitrogen.

Inactive Publication Date: 2011-02-16

NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

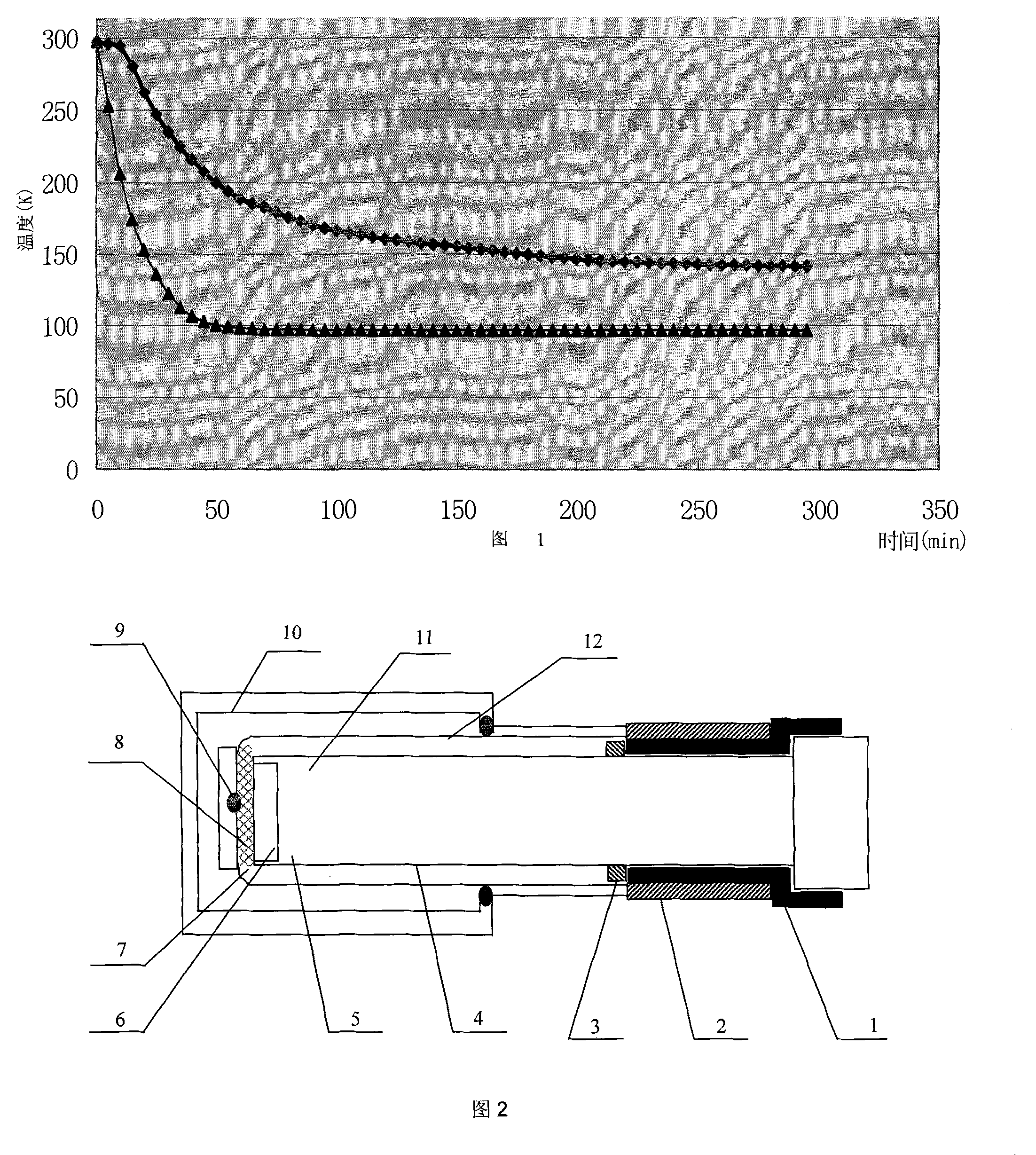

It is difficult to achieve the purpose of cooling above 140K by using a single metal wool heat-conducting material structure, while using a single non-metallic cotton heat-conducting material can reach a refrigeration temperature above 140K, but the cooling time needs to be more than 5 hours, and the loss of liquid nitrogen increases

Reduce effective working time, not suitable for use in refrigeration devices with multiple outputs and different refrigeration temperatures, such as liquid nitrogen refrigeration devices, micro throttling refrigerators and solid refrigerators

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

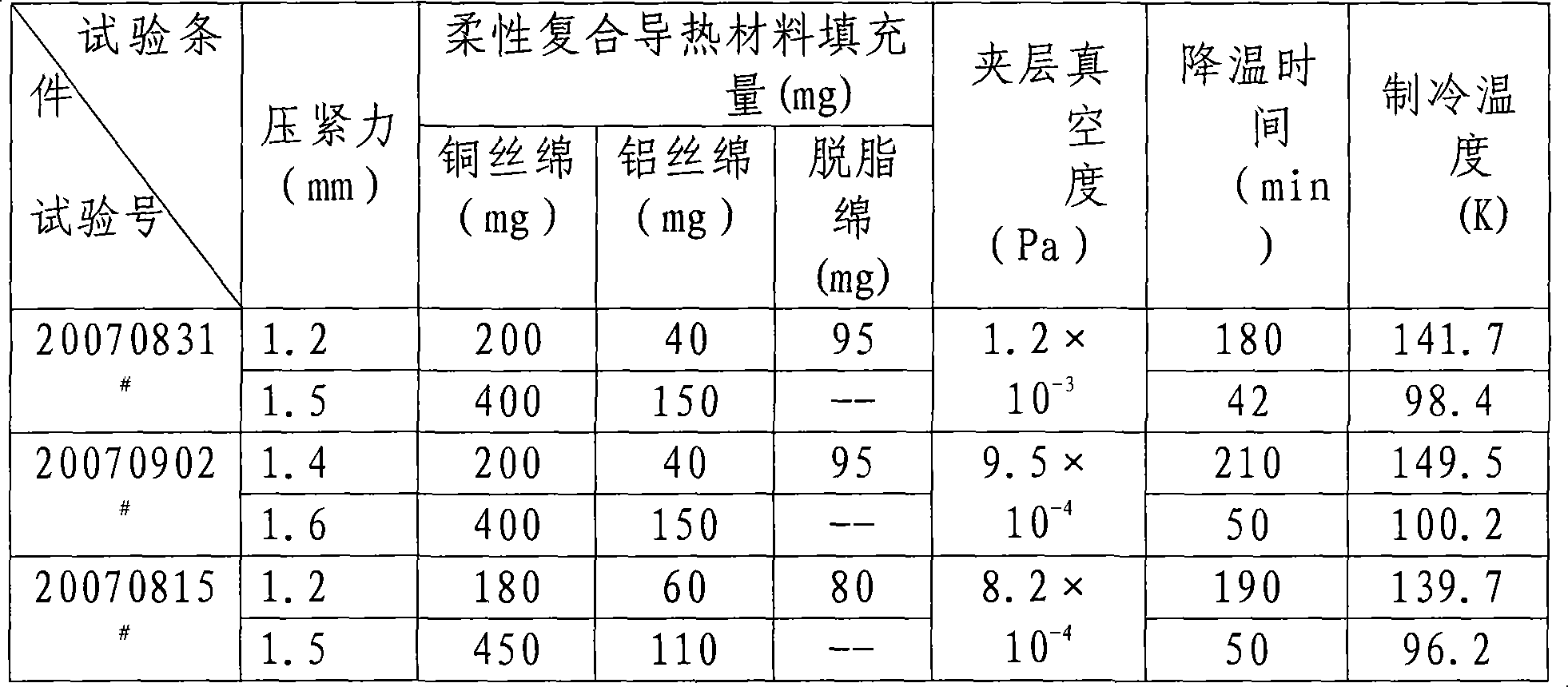

[0009] The specific test conditions for a flexible composite material of a liquid nitrogen refrigeration device are:

[0010] The test conditions are shown in Table 1:

[0011]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

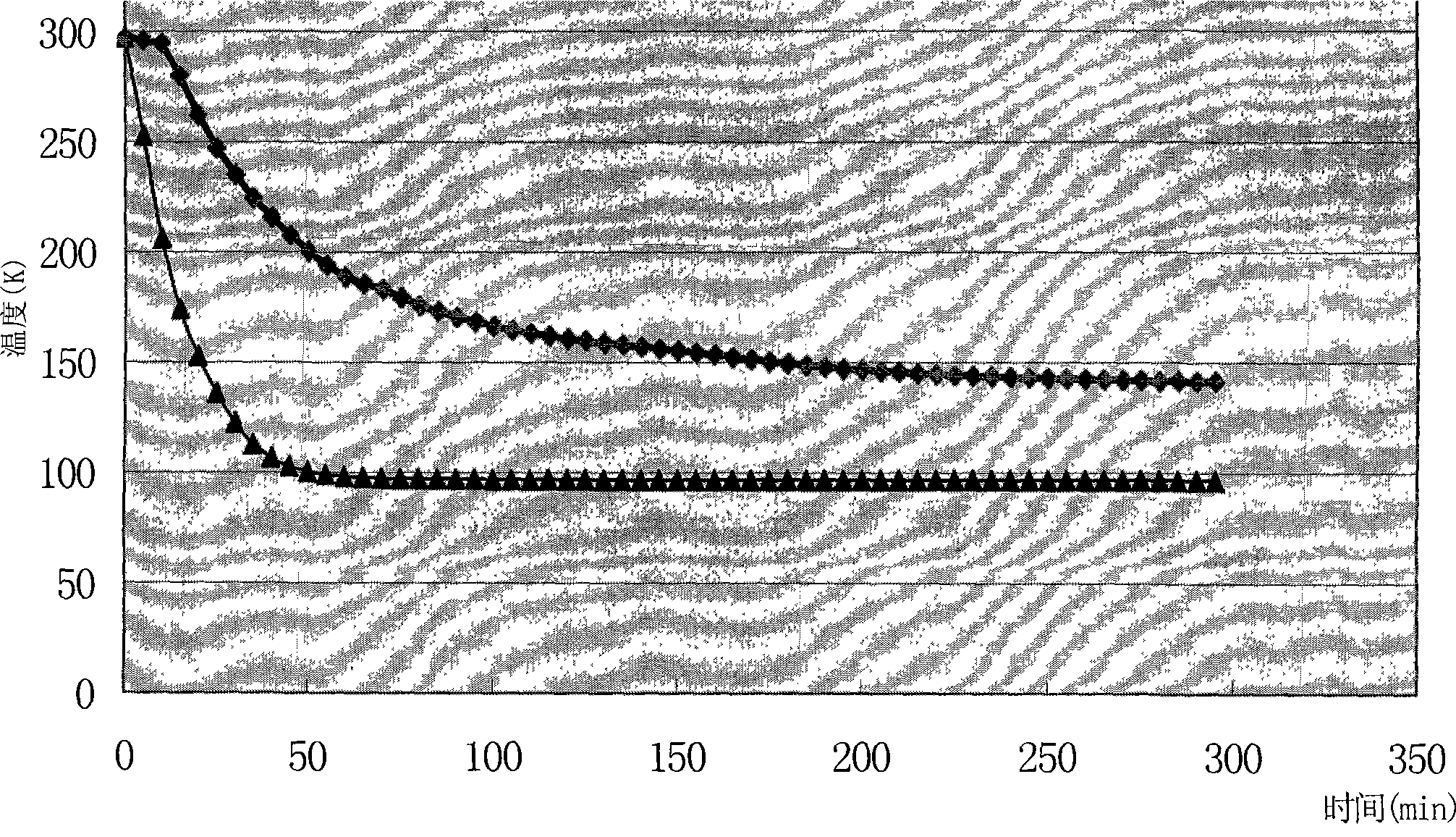

The invention relates to a composite material for a liquid nitrogen refrigerating device, which belongs to the technical field of space low temperature. A flexible composite heat conducting material 8 consists of micron level copper wire cotton, aluminum wire cotton and degreased cotton and is prepared by the following processes: using an electronic scale with the precision of 1 milligram to weigh certain quantity of the copper wire cotton, the aluminum wire cotton and the degreased cotton to perform more than 50 times of even mixing, and making use of the resistance thermal effect of the degreased cotton to perform the coupling at a refrigerating temperature of between 140 and 150 K under the action of the same pressing force. The compounding of the copper wire cotton and the aluminum wire cotton comprises more than 50 times of even mixing and is applicable to the coupling at a refrigerating temperature of between 96 and 105 K; and the compounding of the copper wire cotton, the degreased cotton and the aluminum wire cotton is suitable for the coupling at the refrigerating temperature of between 140 and 150 K. The lengths of the copper wire cotton and the aluminum wire cotton in the mixing process is kept between 8 and 10 millimeters; the flexible composite heat conducting materials with different mixture ratios are made into 'cake' shapes with the diameter phi of 12 millimeters to perform filling; besides, the composite material changes the components of the heat conducting material between the cold end and the hot end of a multi-way detector and the thickness of an equivalent weight layer simultaneously to generate different coupling temperatures.

Description

technical field [0001] The invention relates to a flexible composite material, in particular to a flexible composite heat-conducting material for a liquid nitrogen refrigeration device, and belongs to the field of space low temperature technology. Background technique [0002] Liquid nitrogen refrigeration devices and detectors require coupling mechanisms with small geometric dimensions, high transmission efficiency, and adjustable refrigeration temperature. The key to achieving this goal is to use axial pressing force to change or maintain flexible composite heat-conducting materials in a limited space. Equivalent layer thickness, to achieve the best coupling of different refrigeration temperature points. It is difficult to achieve the refrigeration temperature above 140K by using a single metal wool heat-conducting material structure, but it is possible to achieve a refrigeration temperature above 140K by using a single non-metallic wool heat-conducting material, but the c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K5/14F25D3/10

Inventor 葛瑞宏陈光奇王荣宗施宝毅潘雁频

Owner NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com