Energy-saving wireless remote control arc welding apparatus

A technology of arc welding machine and wireless remote control, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., and can solve the problems of fan service life impact, waste of electric energy, and lack of wireless remote control function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preferred embodiment of the present invention will be described in detail below with reference to the drawings.

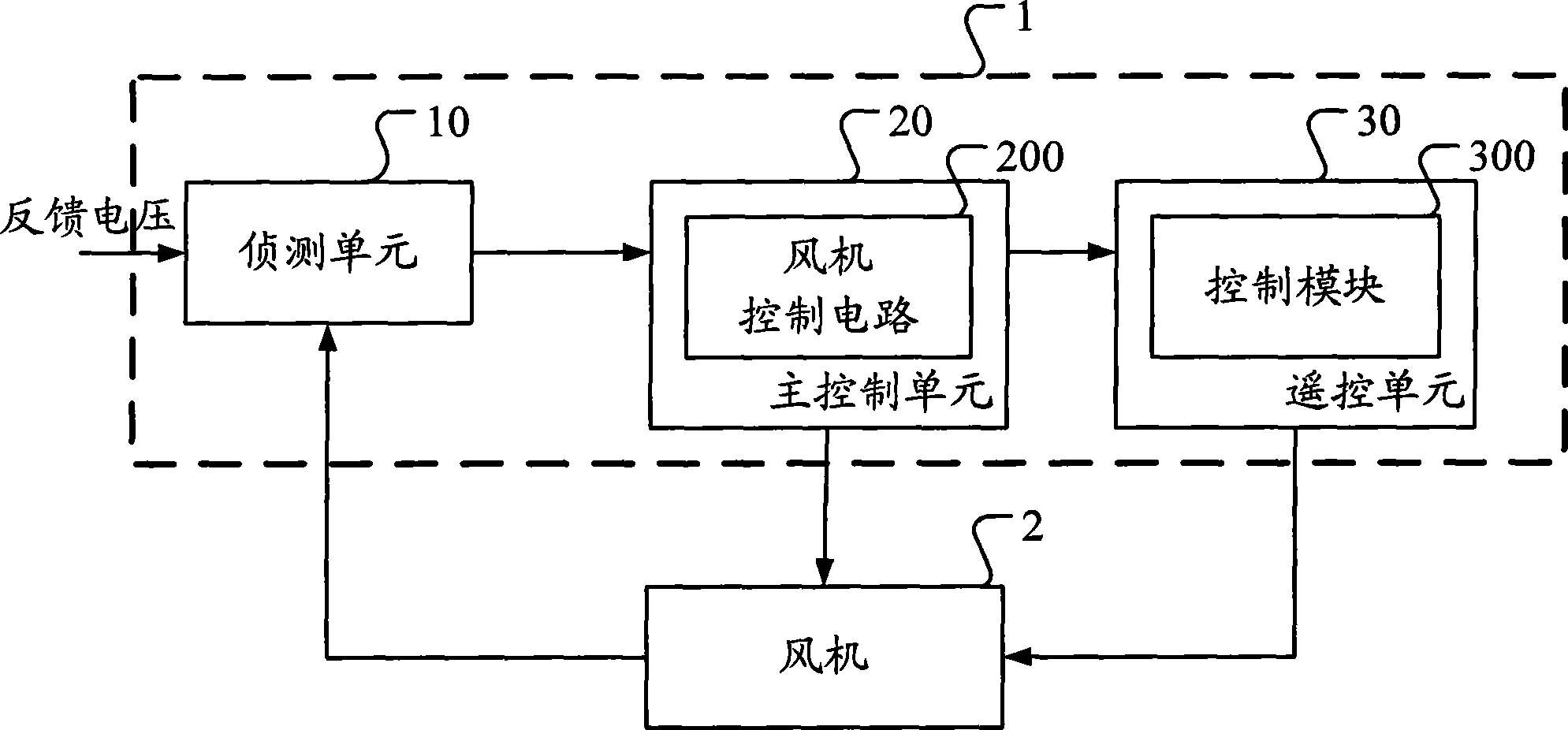

[0012] Such as figure 1 As shown, it is a simplified block diagram of an energy-saving wireless remote-control arc welding machine according to a preferred embodiment of the present invention. As shown in the figure, the energy-saving wireless remote control arc welding machine 1 of the present invention includes a detection unit 10 , a main control unit 20 and a remote control unit 30 .

[0013] The detection unit 10 is used to detect the feedback sampling voltage signal, and obtains the feedback sampling voltage through a socket. In the unwelded state, the no-load voltage output by the welding machine is zero, and the voltage on the socket is 13±2V, so the final output positive and negative no-load voltages are 13±2V; once the welding rod touches the workpiece, it is equivalent to If the socket is short-circuited, the welder immediately outputs a norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com