Surface shape detection apparatus and method for large-bore plane optical element

A technology for detecting optical components and surface shapes, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problem of high optical system design and structural design requirements of large-aperture Hartmann beam expander systems, and it is difficult to meet transient interference Instrument or LTP requirements, inability to detect the surface shape of optical components, etc., to achieve the effect of easy industrial implementation and application, easy quick adjustment, and convenient industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

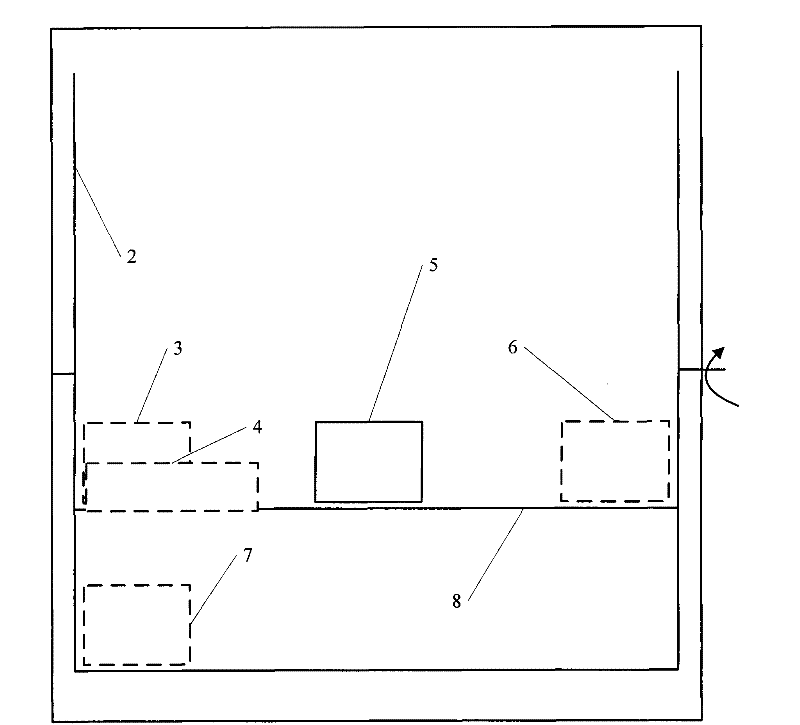

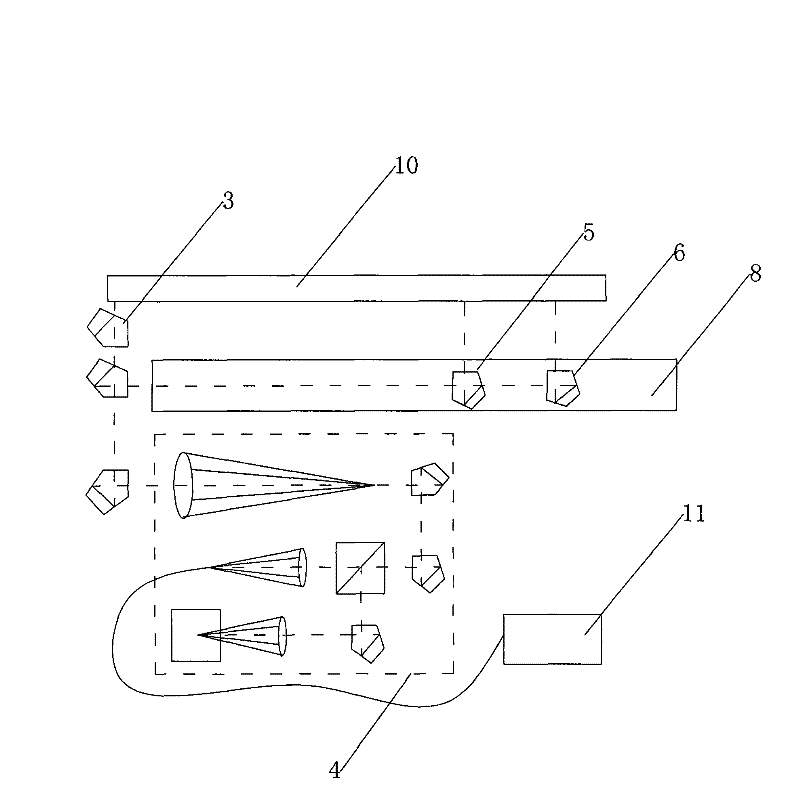

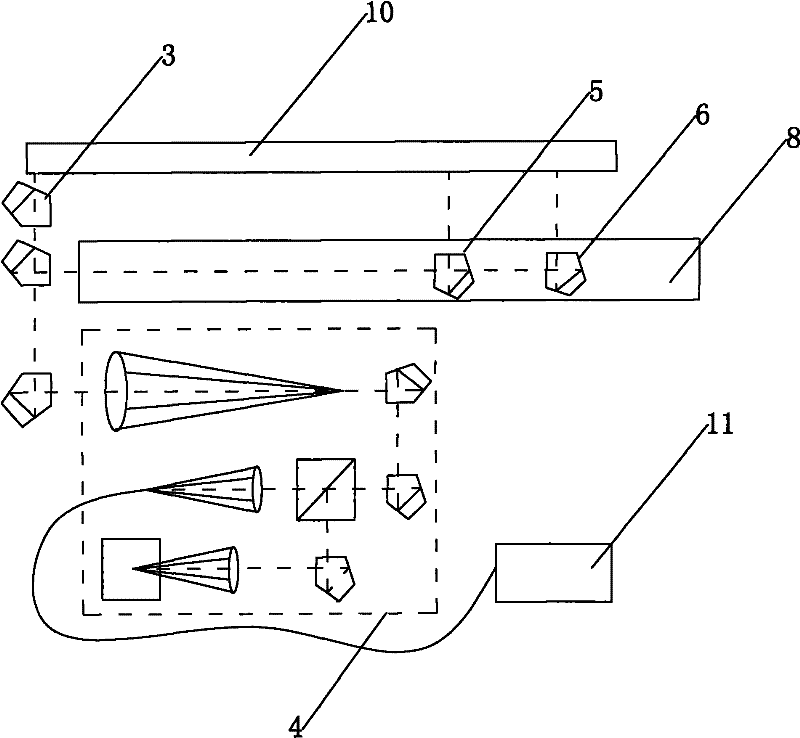

[0031] The surface shape detection device for large-caliber planar optical components includes a frame, an image acquisition and processing system, and a three-dimensional precision motion control system; the three-dimensional precision motion control system includes a vertical motion guide rail that is rotatably installed on the frame, and can Sliding horizontal motion guide rail, the shaft fixedly installed on the vertical motion guide rail is connected with the rotary power mechanism; the image acquisition and processing system includes the first scanning pentaprism arranged on the slider of the horizontal motion guide rail, fixedly installed on the horizontal motion guide rail parallel The first reference pentaprism and the second scanning pentaprism on the axis, the second reference pentaprism fixedly installed on the axis parallel to the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com