Measuring method for residual stress in coating

A technology of internal residual stress and measurement method, which is applied in measuring devices, instruments, and mechanical devices, etc., can solve the problems of increased difficulty in obtaining closed solutions of residual stress in multilayer coatings, coating errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

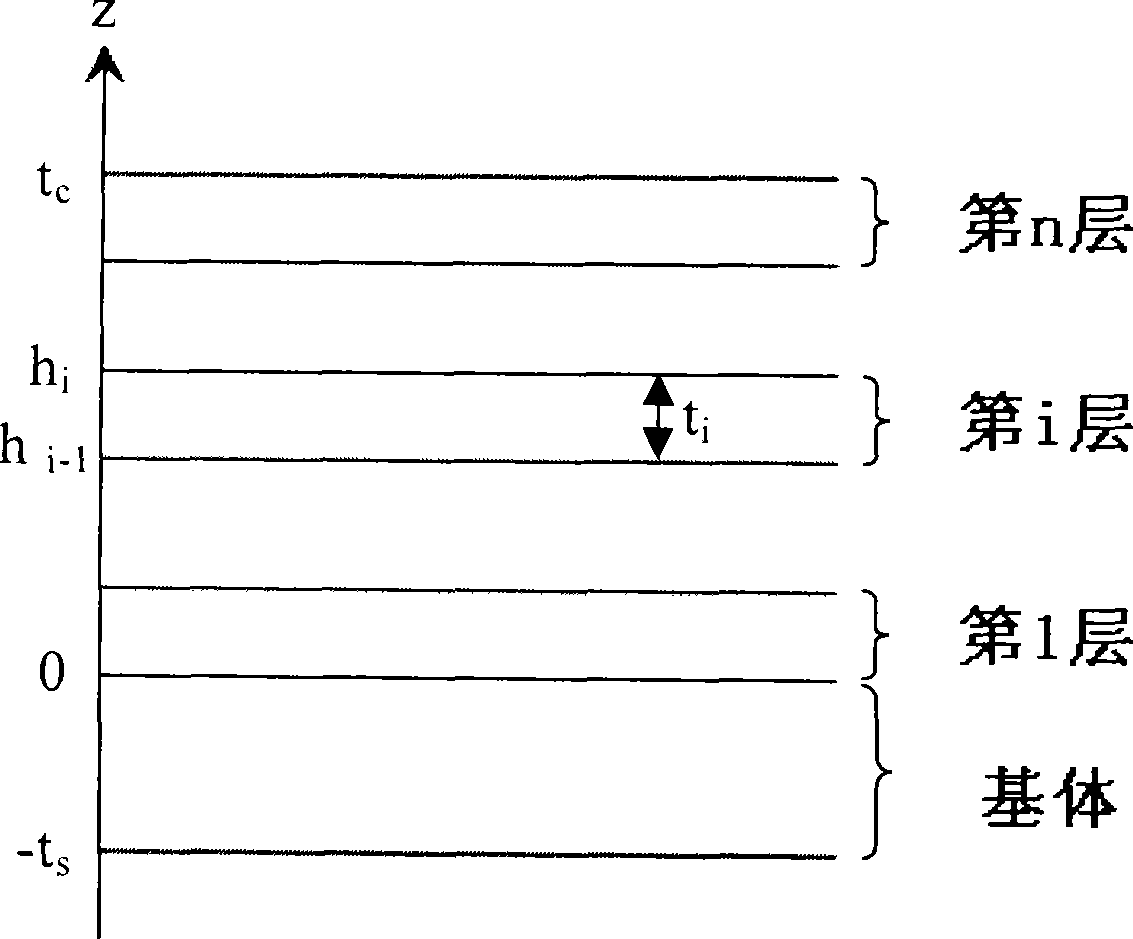

[0030] In the present invention, the composition of coating generally adopts figure 1 The structure shown is represented. figure 1 in, t s Indicates the thickness of the substrate, t c Indicates the thickness of the entire coating, t i Indicates the thickness of the i-th layer of coating, h i Indicates the distance from the upper surface of the i-th coating to the interface between the coating and the substrate, h i-1 Indicates the distance from the lower surface of the i-th coating to the interface between the coating and the substrate.

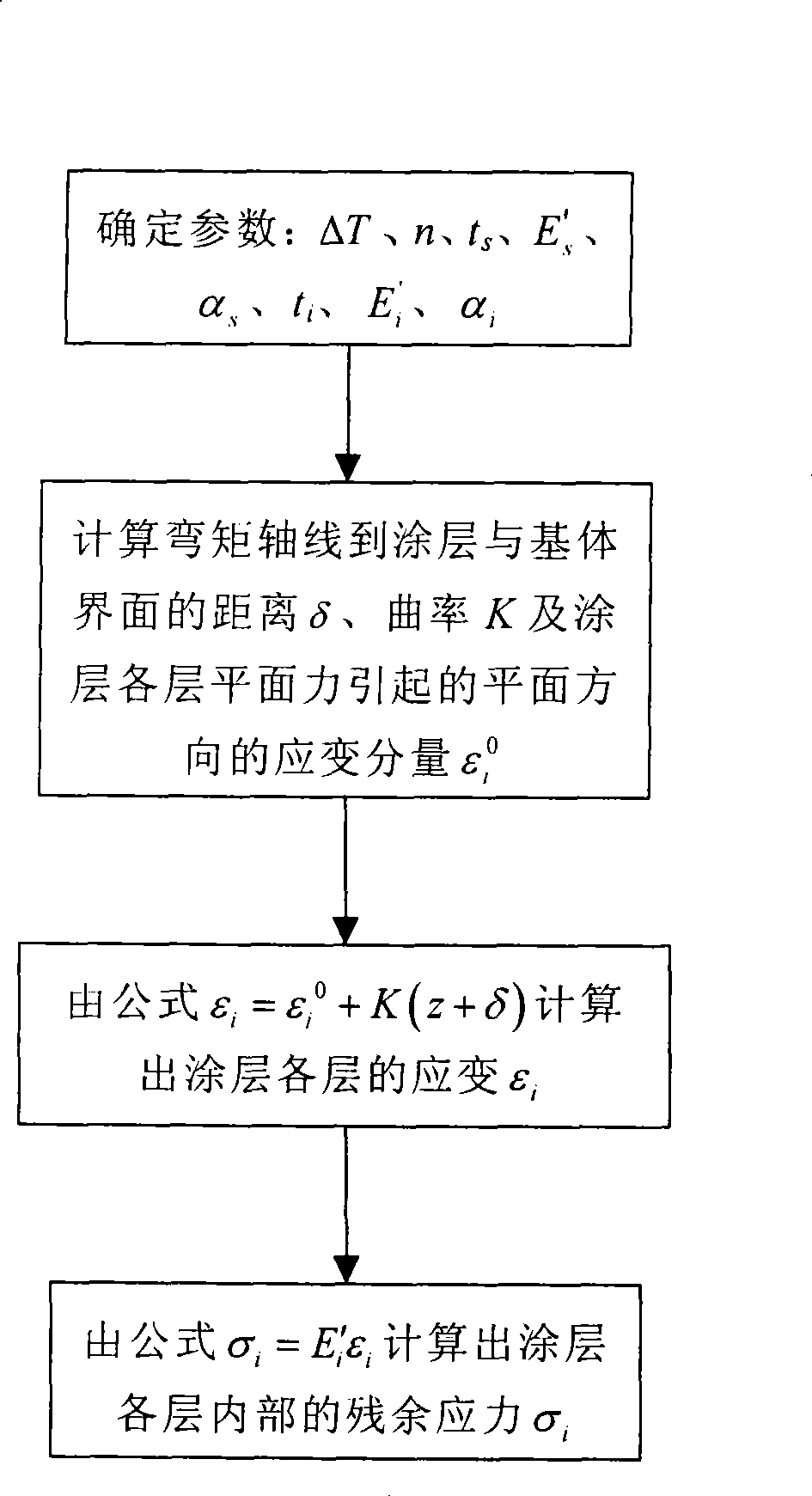

[0031] Such as figure 2 As shown, the determination method of the internal residual stress of the coating includes the following steps:

[0032] 1) Determine the temperature difference ΔT, the number of layers n of the coating to be tested, and the thickness t of the substrate s , effective elastic modulus Coefficient of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com