Recognition device and method for abnormal heating defect rank of electric power apparatus

A technology for power equipment and defect levels, which is applied to measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problem of inability to directly judge the level of power equipment, and achieve the effect of strong practicability, failure avoidance, and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

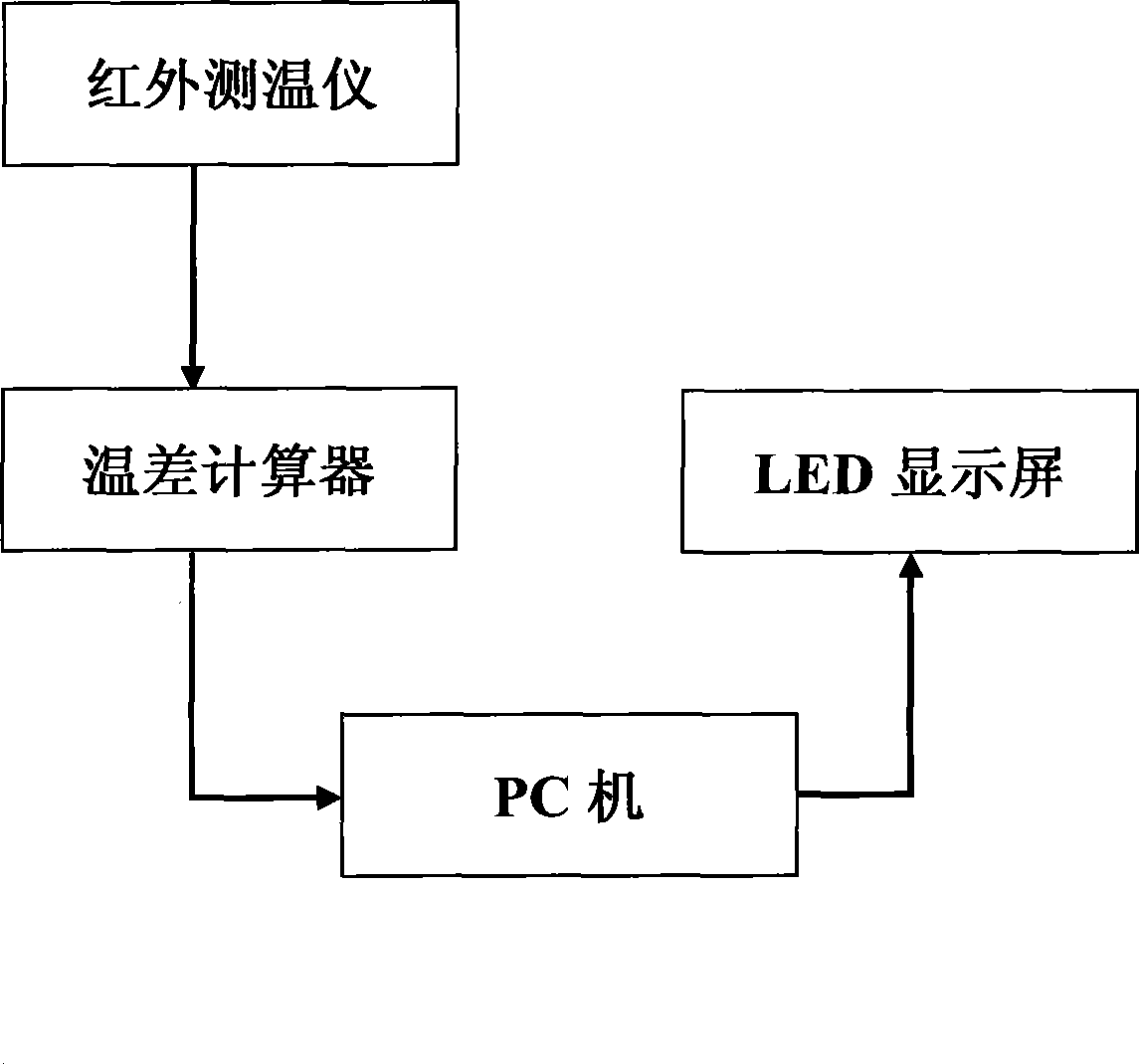

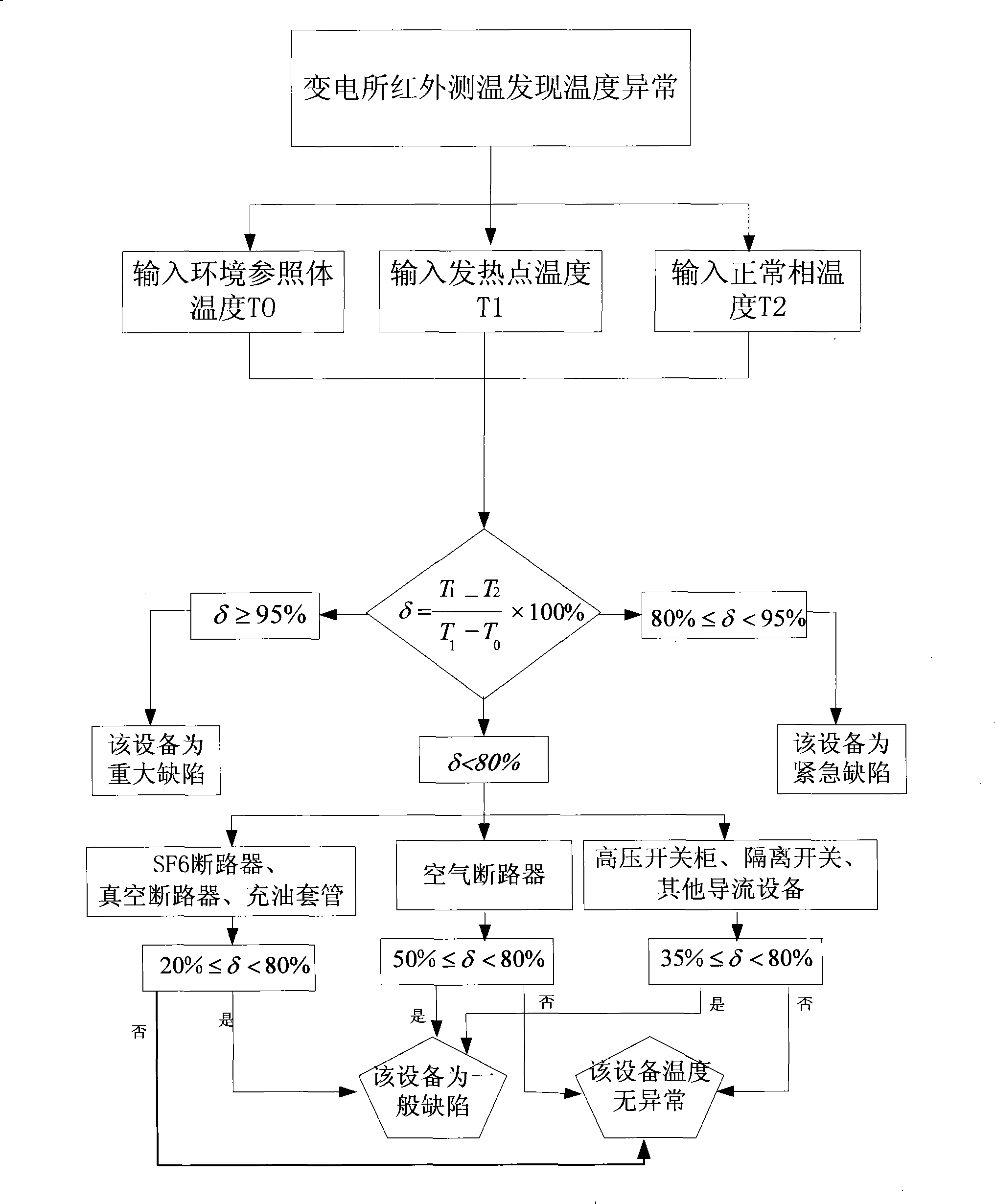

[0024] The temperature of a certain phase of oil-filled bushing equipment in a substation was measured by infrared thermometer as T1 = 100 °C, the temperature of the normal phase was T2 = 30 °C, and the temperature of the environmental reference body at that time was T0 = 25 °C. The infrared thermometer transmits the three measured temperature values to the temperature difference calculator, and the temperature difference calculator is based on the formula δ = T 1 - T 2 T 1 - T 0 × 100 % The relative temperature difference δ=93.3% is obtained, and the temperature difference calculator sends the value of the relative temperature difference δ to the PC. The PC judges that 80%≤δ<95%, and the PC displays the information as "major defect...

Embodiment 2

[0026] The temperature of a certain phase of the air circuit breaker equipment in a substation is measured by infrared thermometer as T1=120°C, the temperature of the normal phase is T2=30°C, and the temperature of the environmental reference body at that time is T0=28°C. The infrared thermometer transmits the three measured temperature values to the temperature difference calculator, and the temperature difference calculator is based on the formula δ = T 1 - T 2 T 1 - T 0 × 100 % The relative temperature difference δ=97.8% is obtained, the temperature difference calculator sends the value of the relative temperature difference δ to the PC, and the PC judges that δ≥95%, and the PC displays the information as "emergency defect" throu...

Embodiment 3

[0028] The temperature of a certain phase of the SF6 circuit breaker equipment in a substation was measured by infrared thermometer as T1=90°C, the temperature of the normal phase was T2=40°C, and the temperature of the environmental reference body at that time was T0=25°C. The infrared thermometer transmits the three measured temperature values to the temperature difference calculator, and the temperature difference calculator is based on the formula δ = T 1 - T 2 T 1 - T 0 × 100 % The relative temperature difference δ=76.9% is obtained, the temperature difference calculator sends the value of the relative temperature difference δ to the PC, and the PC judges that δ<80%, and then performs the secondary identification operation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com