Can

A technology of cans and metal sheets, applied in the field of cans, which can solve problems such as unbearable force and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

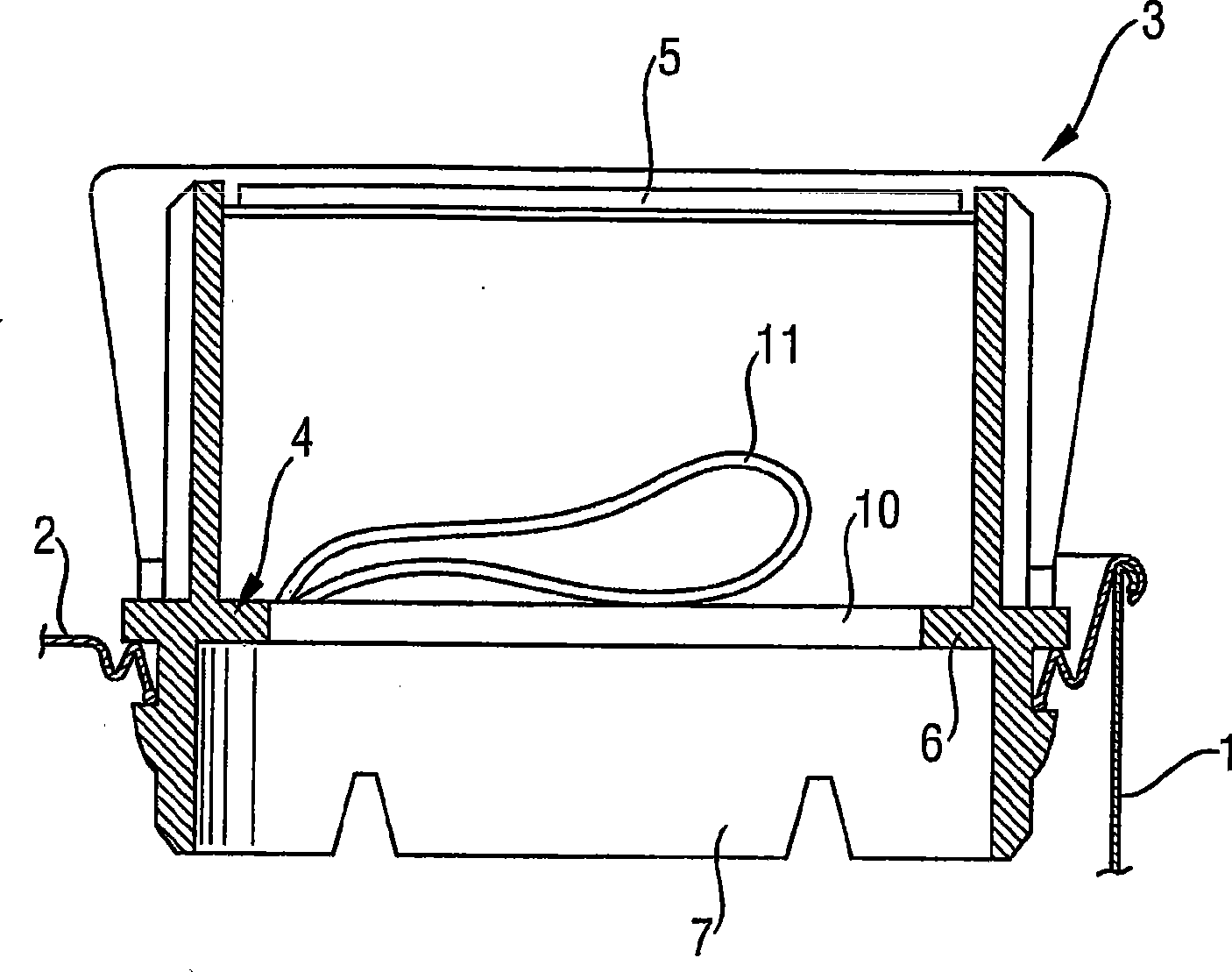

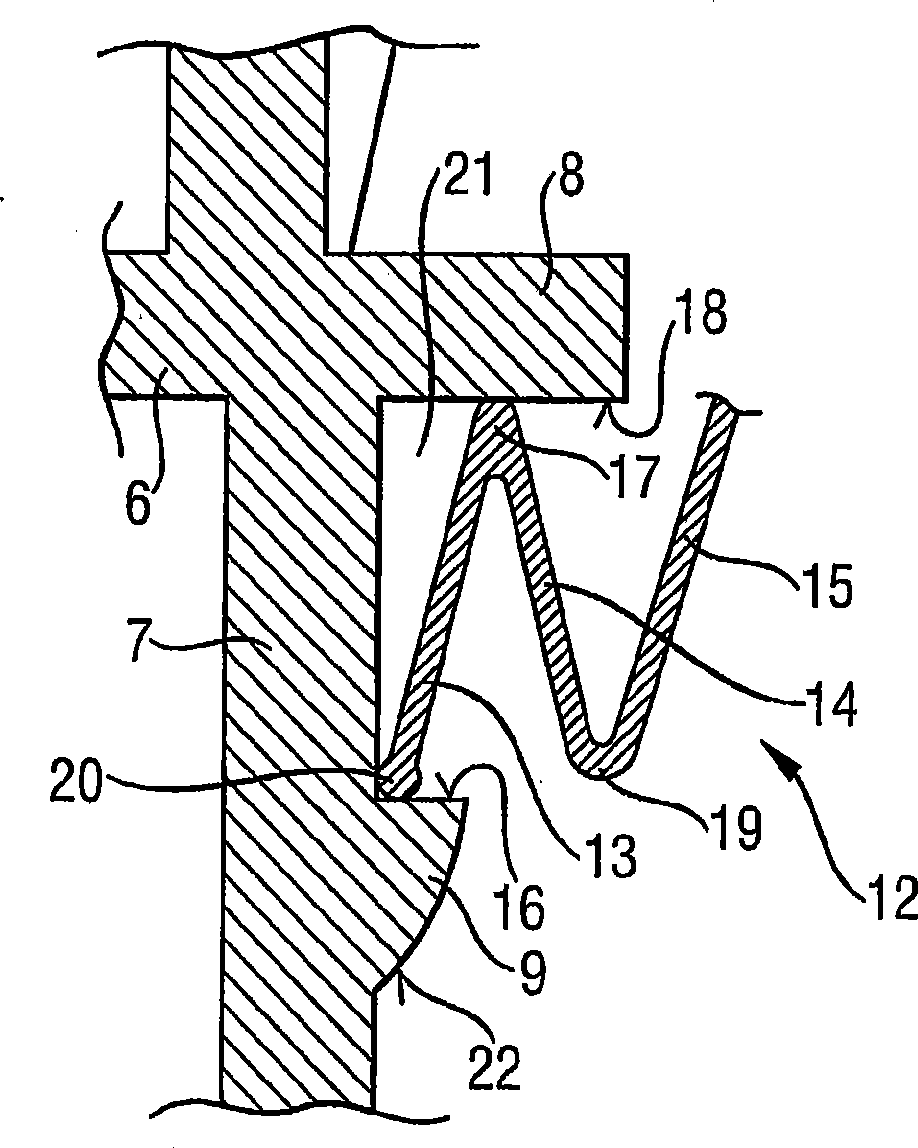

[0019] figure 1 The can has a cylindrical wall 1 closed at the top by a sheet metal lid 2 provided with a sealing element 3 . The sealing element 3 consists of a bottom part 4 and a screw cap 5 screwed into the bottom part 4 .

[0020] The bottom part 4 comprises a plate 6 on which is formed an annular cylindrical downward extension 7 constituting a retaining part. The plate 6 continues beyond the diameter of the retaining portion 7 as a flange, referred to herein as a second protrusion 8 . Below the second projection 8 there is arranged a first projection 9 which is likewise annular.

[0021] A safety cover is provided in the plate 6 , which can be torn off by means of a pull ring 11 . On the one hand, this provides an additional measure of safety against spilling or contaminating the contents before the can is opened for the first time, and on the other hand, it allows the user to determine whether the can is in original condition or has already been opened.

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com