Solid-liquid separation device and garbage disposer

A technology of domestic waste and solid-liquid separation, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve problems such as wear and gap expansion, and achieve the effect of good sliding and wear prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] (The overall structure of the domestic waste treatment plant)

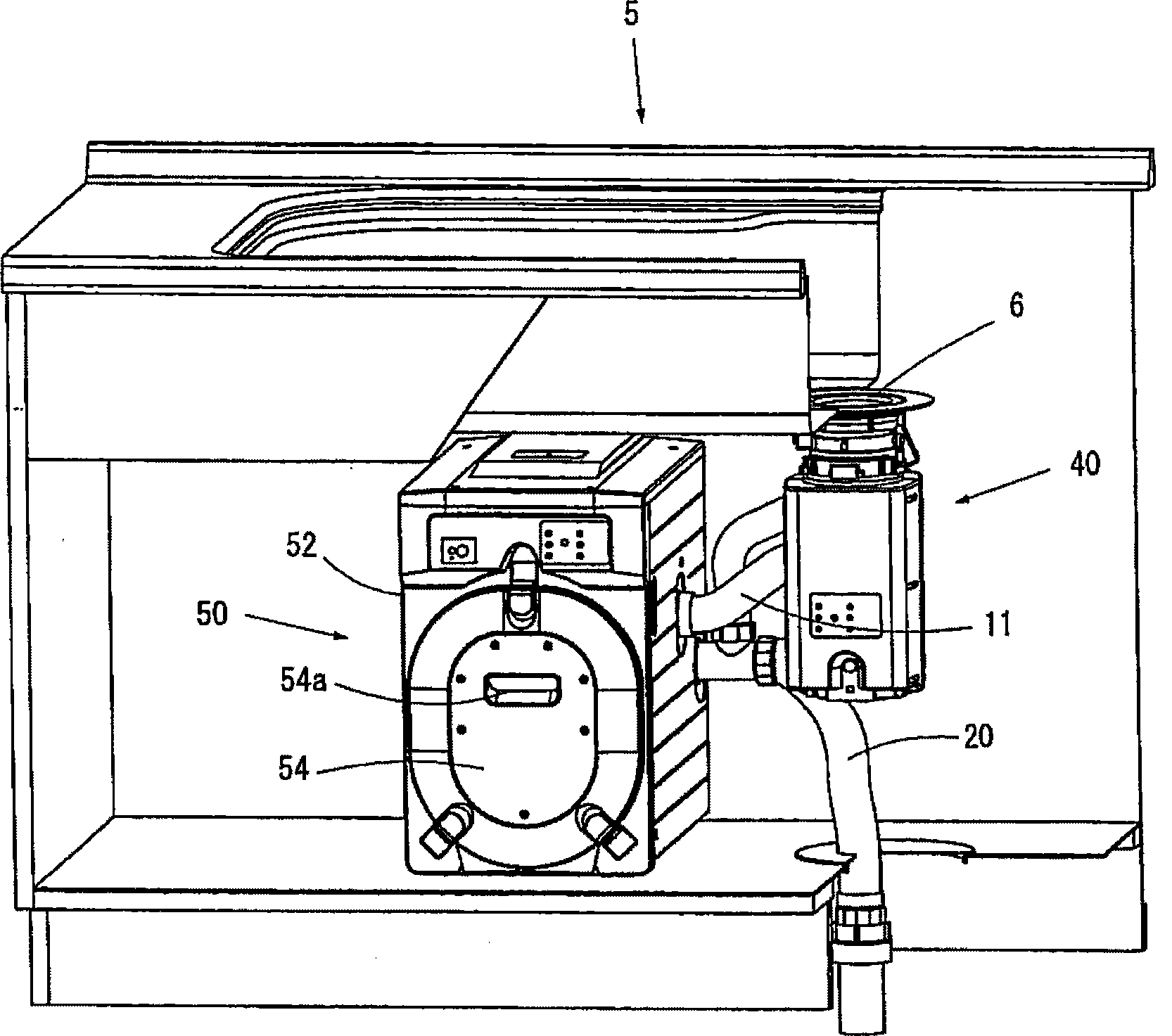

[0058] figure 1 Shown is a situation in which a domestic waste treatment device having a solid-liquid separation device of the present invention is installed on a kitchen sink 5 .

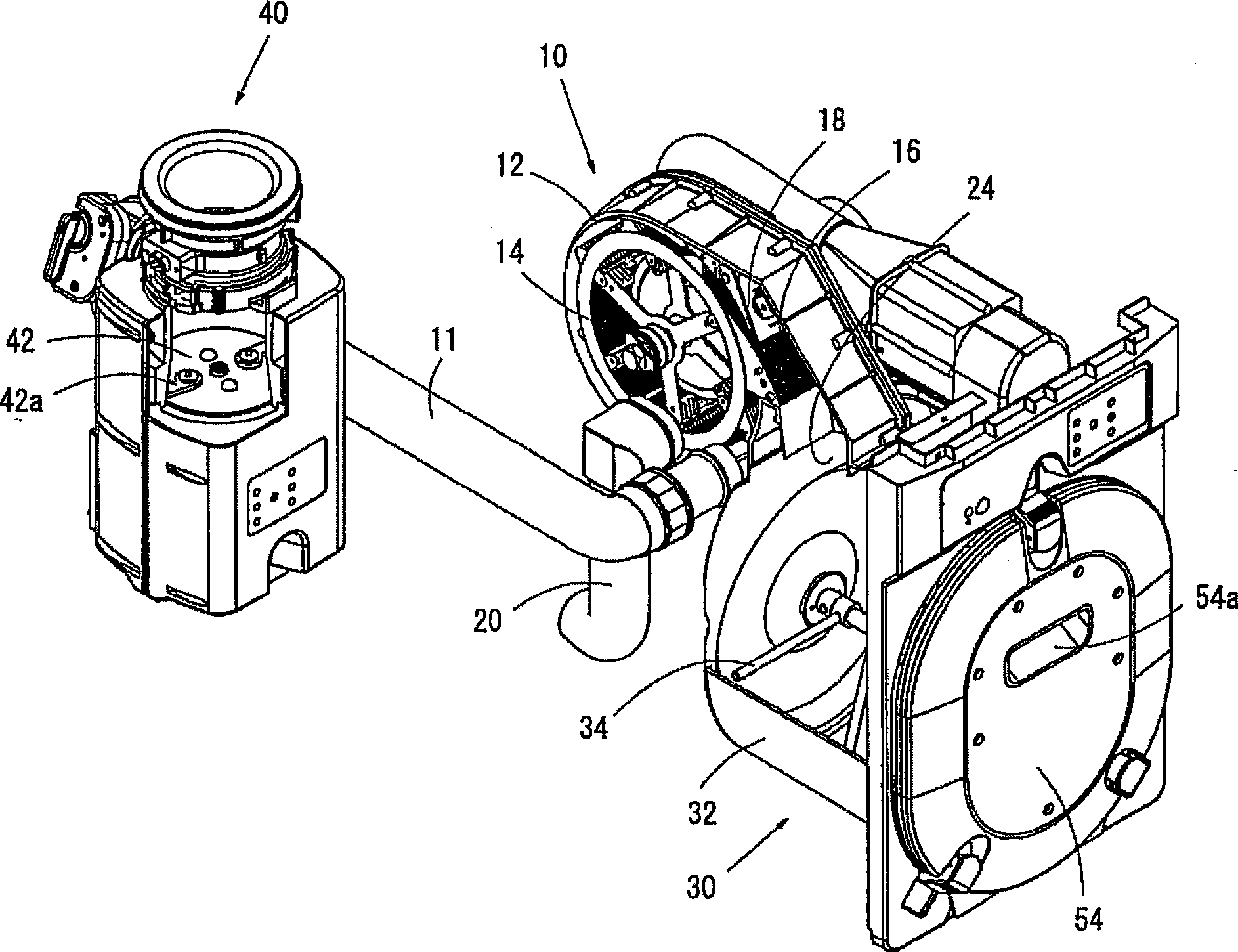

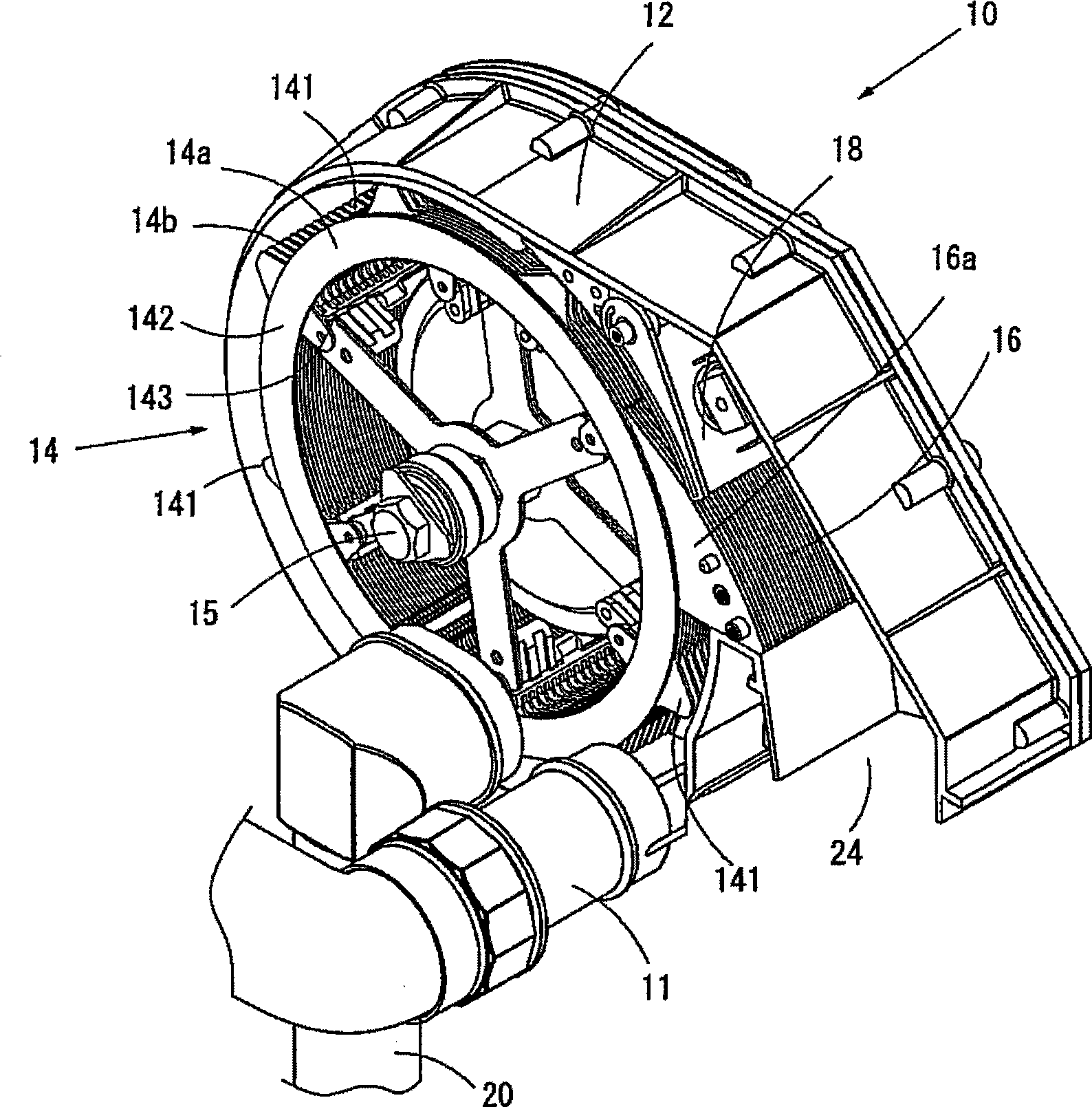

[0059] The domestic waste treatment device includes: a crusher 40, which is hung and installed at the lower part of the drain 6 of the sink 5; a body 50, which processes the domestic waste discharged from the crusher 40 together with water. The main body 50 is configured such that the solid-liquid separation device 10 and the drying device 30 are accommodated in a box-shaped casing 52 .

[0060] A front cover 54 is detachably attached to the front surface of the main body 50 , and the front cover 54 serves as a front portion of the storage 32 of the drying device 30 . A handle 54a is provided on the front surface of the front cover 54, and the storage device 32 can be pulled out by hooking the handle 54a and pulling it forwar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap