Cage supporting and accepting device and method of hoisting vessel

A technology for stabilizing tanks and containers, which is applied in the field of devices for undertaking and stabilizing tank cages. It can solve the problems of large amount of basic engineering reconstruction, high operation requirements, and cumbersome operations, and achieve the effect of less reconstruction engineering, improved lifting efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

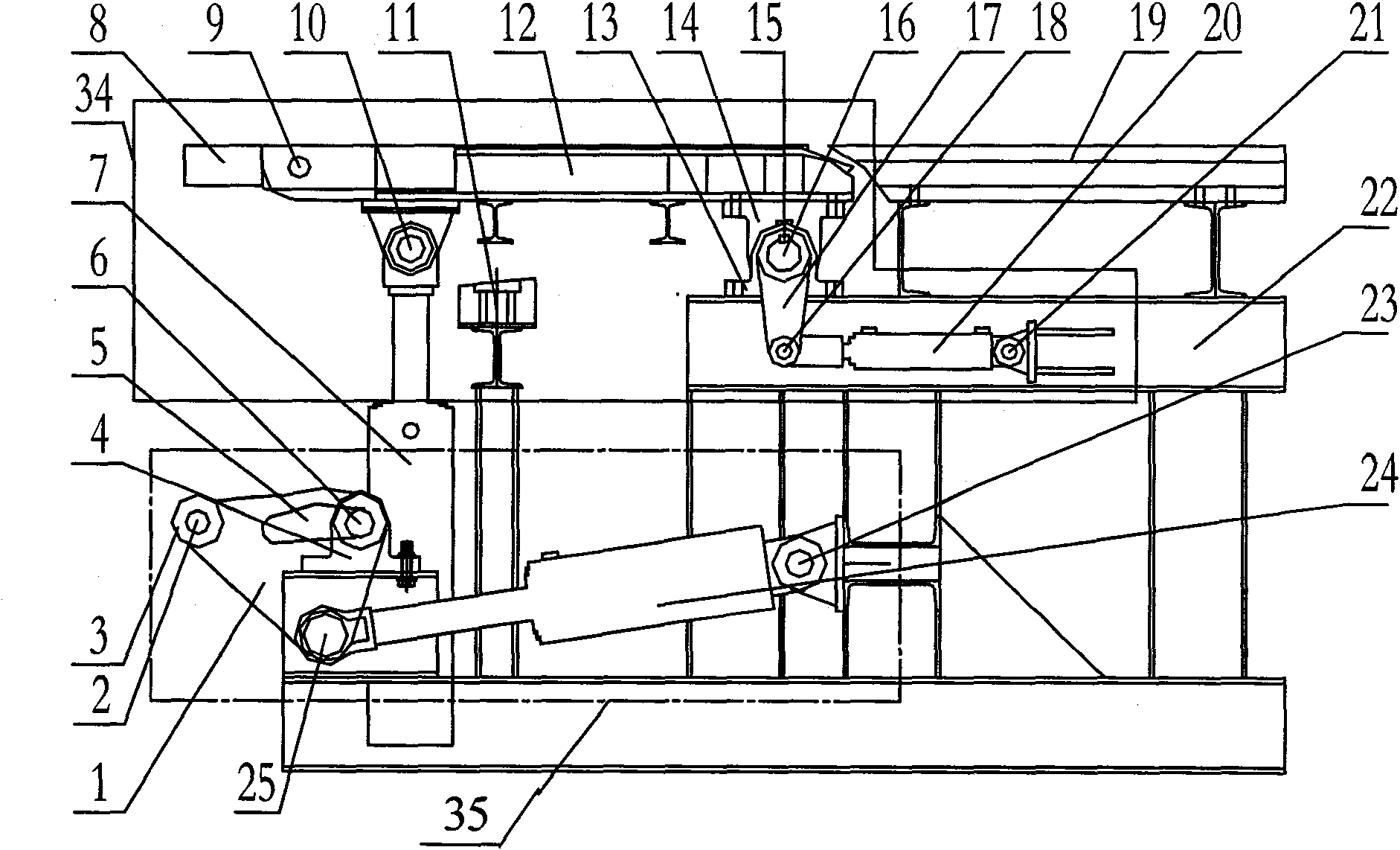

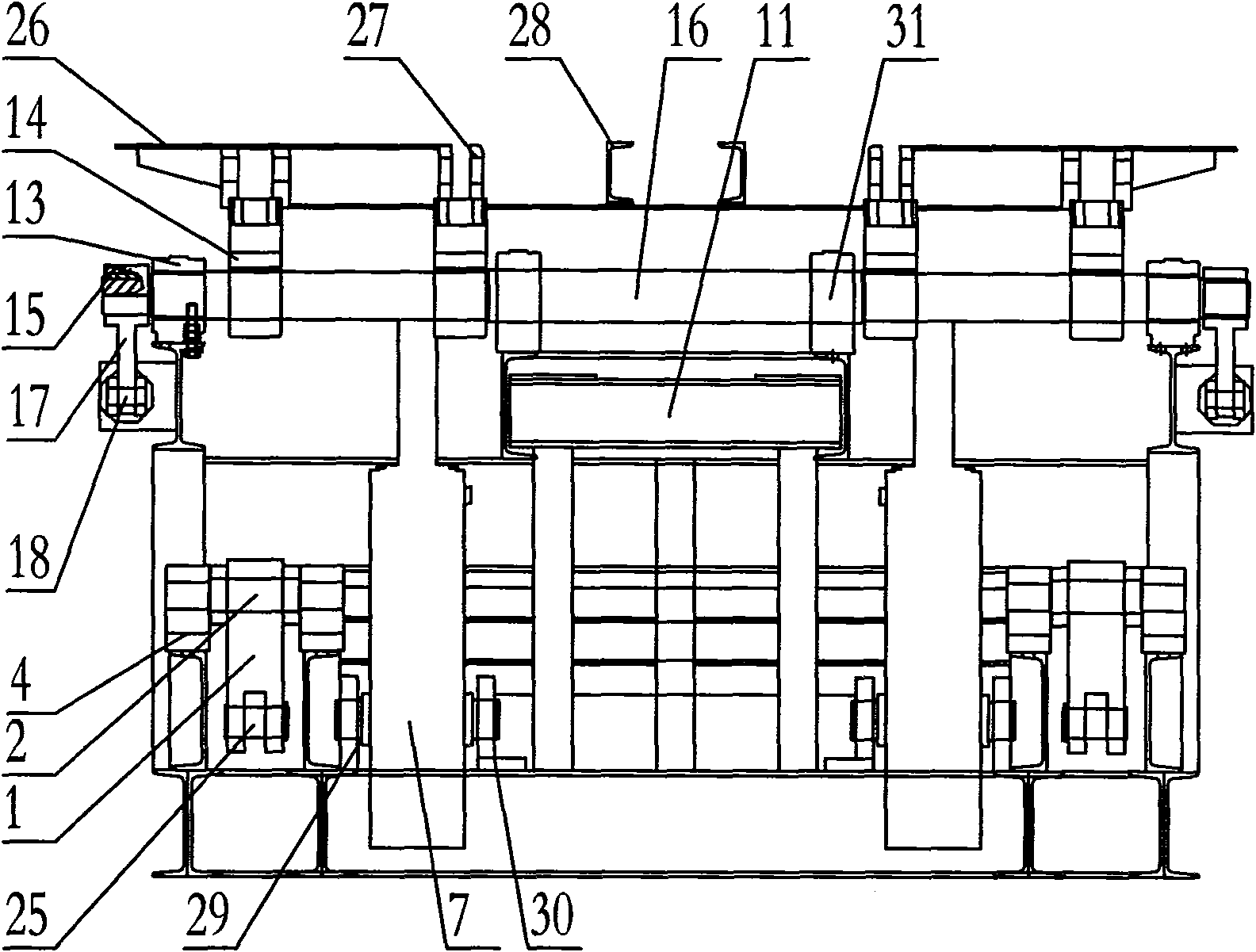

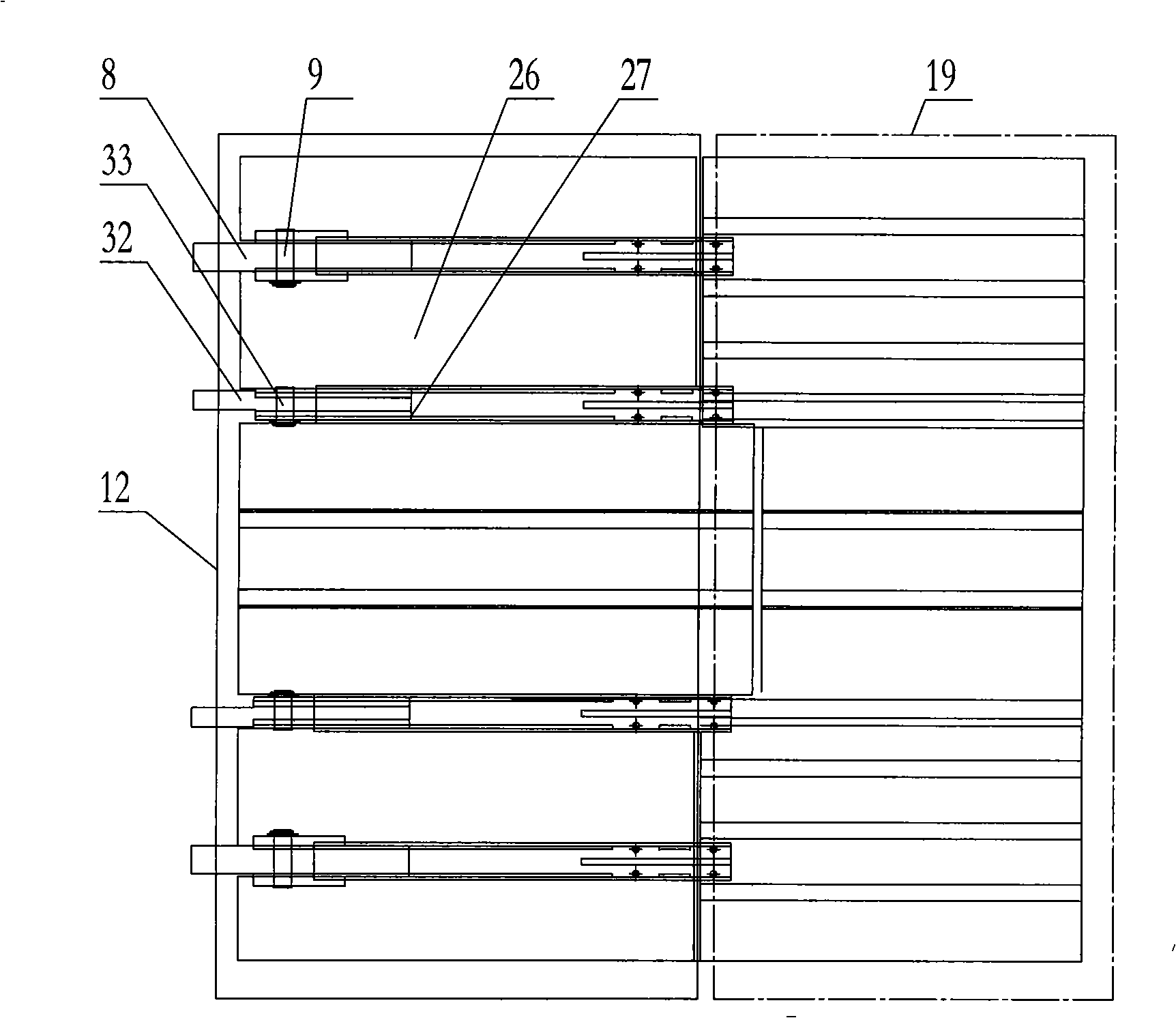

[0028] figure 1 As shown, the tank stabilizing device of the present invention is mainly composed of a frame 22 , a receiving device 35 , a rocker arm connection device 34 and a rocker arm rear platform 19 . The bottom of frame 22 is provided with the receiving device 35 that accepts cage chassis, and the top is provided with the rocking arm connecting device 34 of stabilizing cage, and the afterbody of rocking arm connecting device 34 is provided with rocking arm rear platform 19. The receiving device 35 includes a receiving cylinder 24, supporting claw 1, roller 3, receiving shaft 6, receiving bearing 4 and receiving cylinder seat 23; The rear end of the body is hinged with the receiving cylinder seat 23 through a pin shaft, and the receiving cylinder seat 23 is fixed on the frame 22; the supporting claw 1 is an asymmetric arc surface triangle, and an arc groove 5 is opened at the upper end; the accepting shaft 6 passes through the arc groove 5 is installed on the receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com