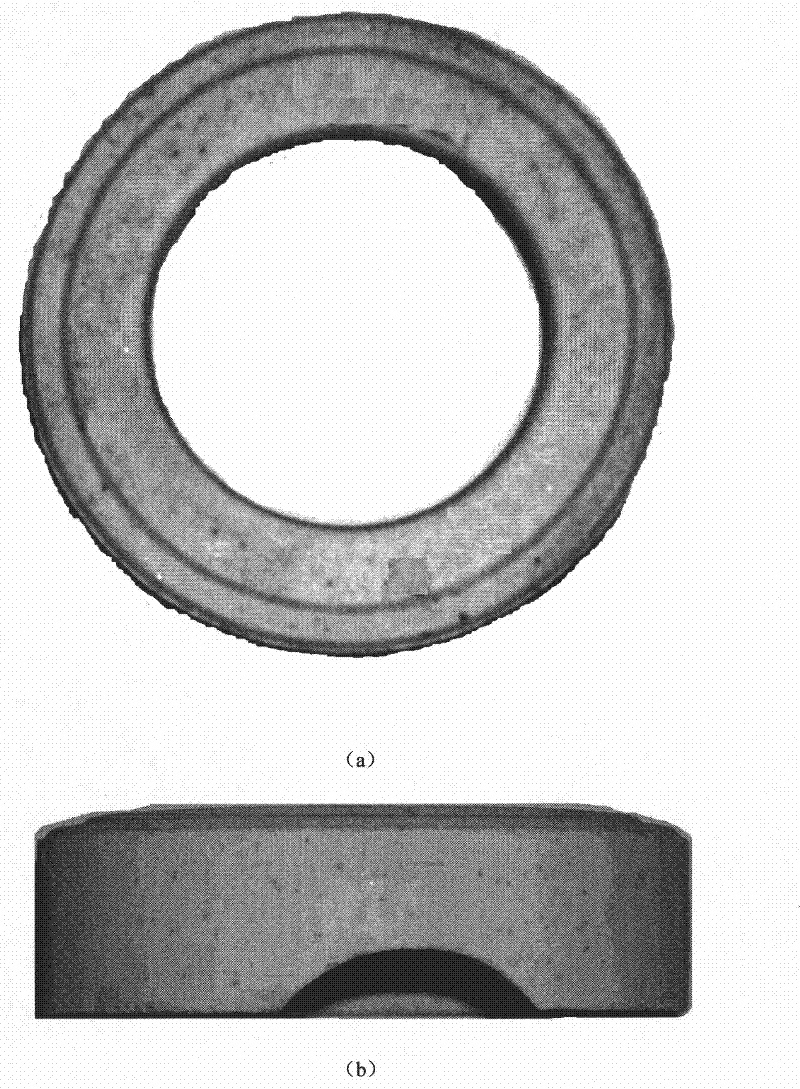

Mullite-corundum deflecting yoke core frame for burning and preparation thereof

A technology of corundum and mullite, which is applied in the preparation and manufacture of fired mullite-corundum deflection magnetic core holders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

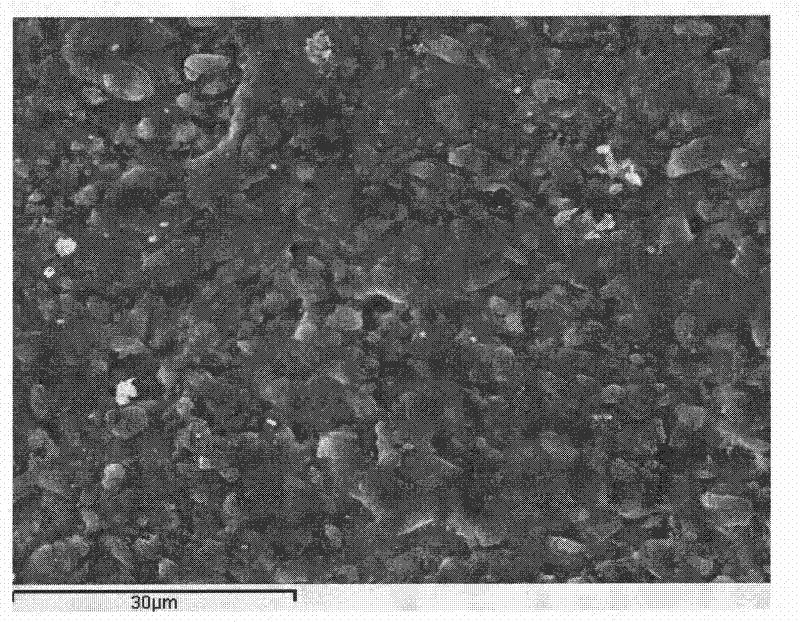

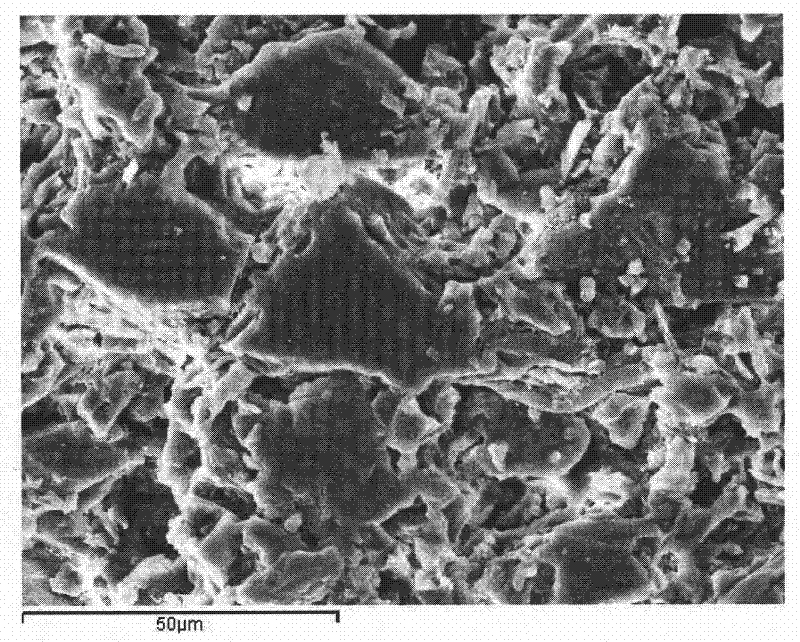

Image

Examples

Embodiment 1

[0027] In this embodiment, the usage of fused corundum is 40% (weight), the usage of fused mullite is 30% (weight), the usage of Suzhou clay is 25% (weight), α-Al 2 o 3 Micronized 5%.

[0028] Mineralizer MgCO 3 5% of raw material weight, BaCO 3 2% of the raw material weight.

[0029] The mullite-corundum deflection magnetic core setter of this embodiment is prepared according to the following method:

[0030] The above-mentioned raw materials and mineralizers are accurately weighed and mixed, and then a cellulose solution binder (organic temporary binder) is added as usual. After mixing, molding, and drying, they are placed in a sintering furnace at 1480 ° C. After firing The mullite-corundum deflection magnetic core bearing seat is selected and the finished product is obtained.

Embodiment 2

[0032] The difference between this embodiment and Example 1 is that the usage of fused corundum is 43% (weight), the usage of fused mullite is 30% (weight), and the usage of Suzhou clay is 20% ( weight), α-Al 2 o 3 Micropowder 7%, mineralizer take MgCO 3 7% of raw material weight, BaCO 3 Be 1% of raw material weight and all the other are with embodiment 1.

Embodiment 3

[0034]The difference between this embodiment and Example 1 is that the usage of fused corundum is 35% (weight), the usage of fused mullite is 35% (weight), and the usage of Suzhou clay is 24% ( weight), α-Al 2 o 3 Micropowder 6%, mineralizer take MgCO 3 6% of raw material weight, BaCO 3 Be 1% of raw material weight, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com