Manufacture and application of a polyamide antiblock master batch

A technology of open-ended masterbatch and polyamide, which is applied in the mixing field of preparing open-ended polyamide masterbatch, and can solve the problems of unspecified addition method and method, corrosion of metering screw and extruder screw, backflow of feeding section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

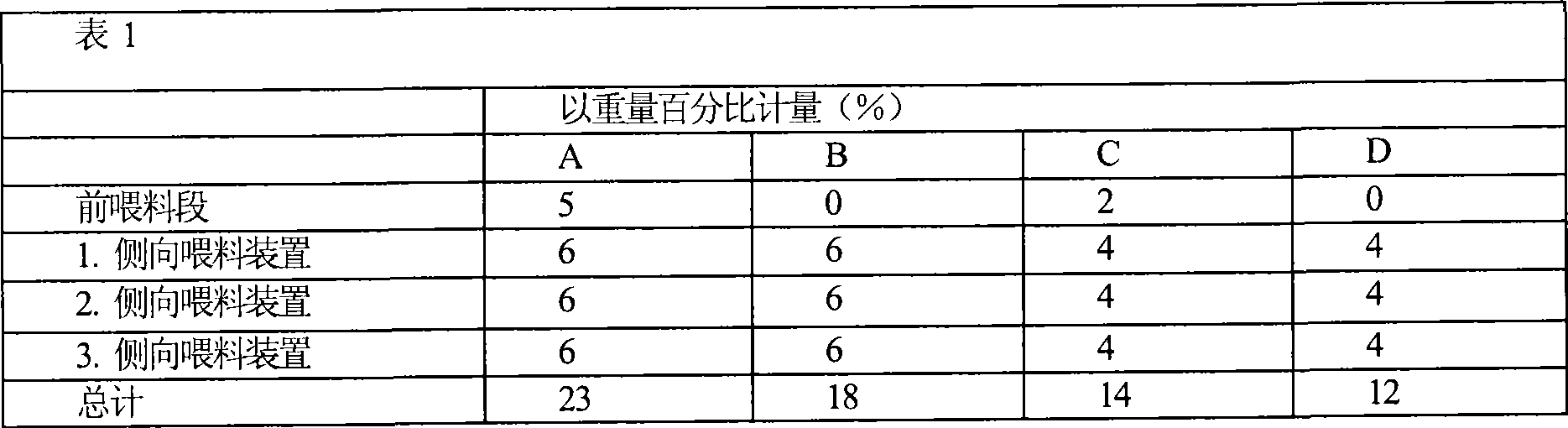

Method used

Image

Examples

Embodiment Construction

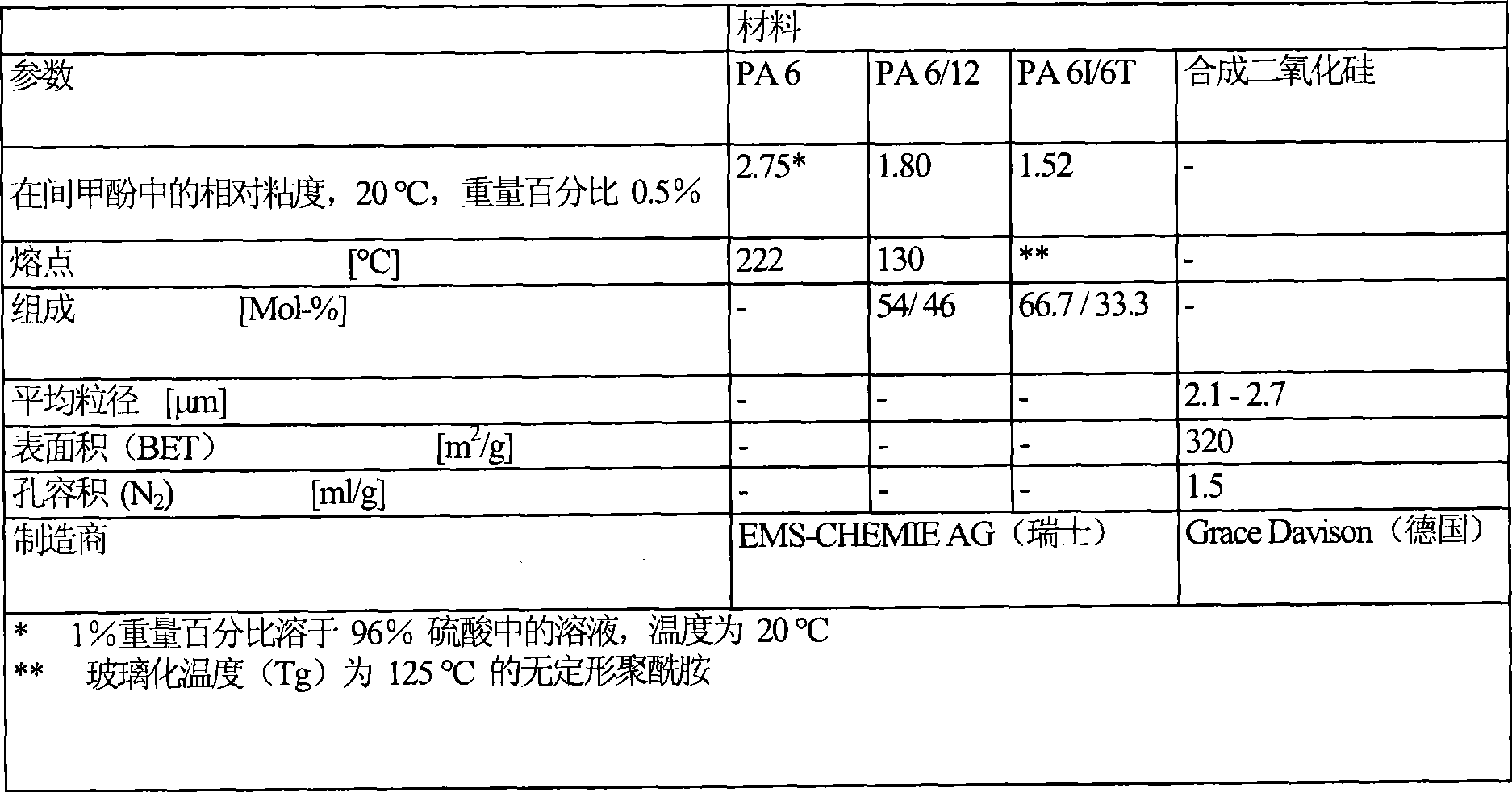

[0008] The method described in the present invention uses synthetic amorphous fine particle silica without surface treatment as blocker and filler, hereinafter referred to as synthetic silica.

[0009] The carrier polyamide is preferably selected from PA6, PA66, PA11, PA12, PA1212, PA6 / 12, PA6 / 66, PA6 / 69, PA6I / 6T and mixtures thereof, especially PA6, PA12, PA6 / 12 and PA6I / 6T and mixtures thereof.

[0010] Depending on the carrier polyamide used, the minimum temperature of the extruder is at least 180°C, suitably 220°C, particularly suitably 250°C, most suitably 250-300°C. Cool the maximum temperature of the extruder barrel in the front feeding section to 60°C, preferably to 40°C, especially to 25°C.

[0011] In the kneading method for preparing polyamide open-ended masterbatch according to the present invention, it is suitable to use synthetic amorphous fine particle silica without surface treatment. The average particle diameter of such synthetic silica is 1-8 μm, suitably ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com