High-efficiency air-conditioner heat exchanger

A technology for heat exchangers and air conditioners, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve problems such as poor effect and failure, and achieve the effect of uniform temperature and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

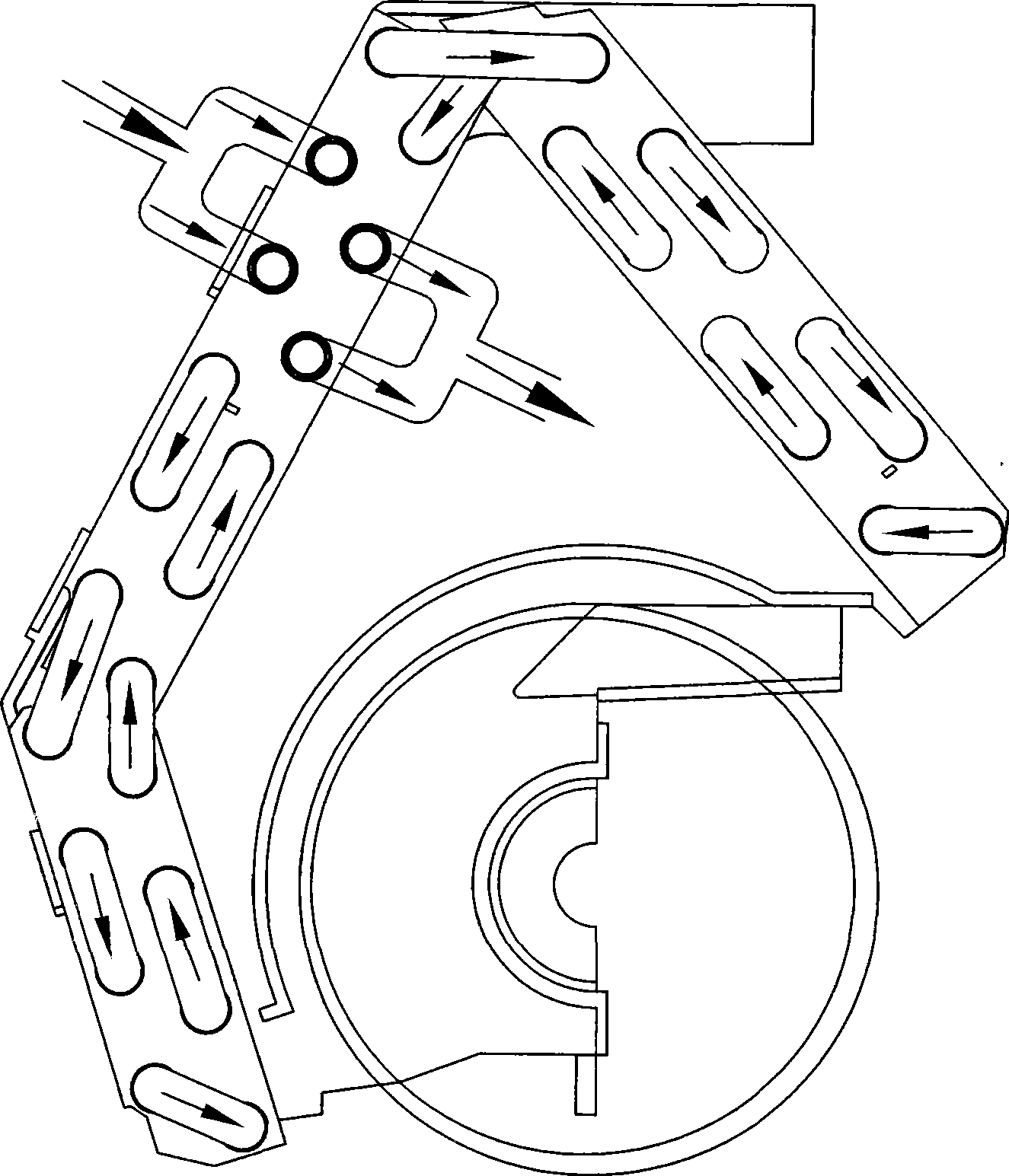

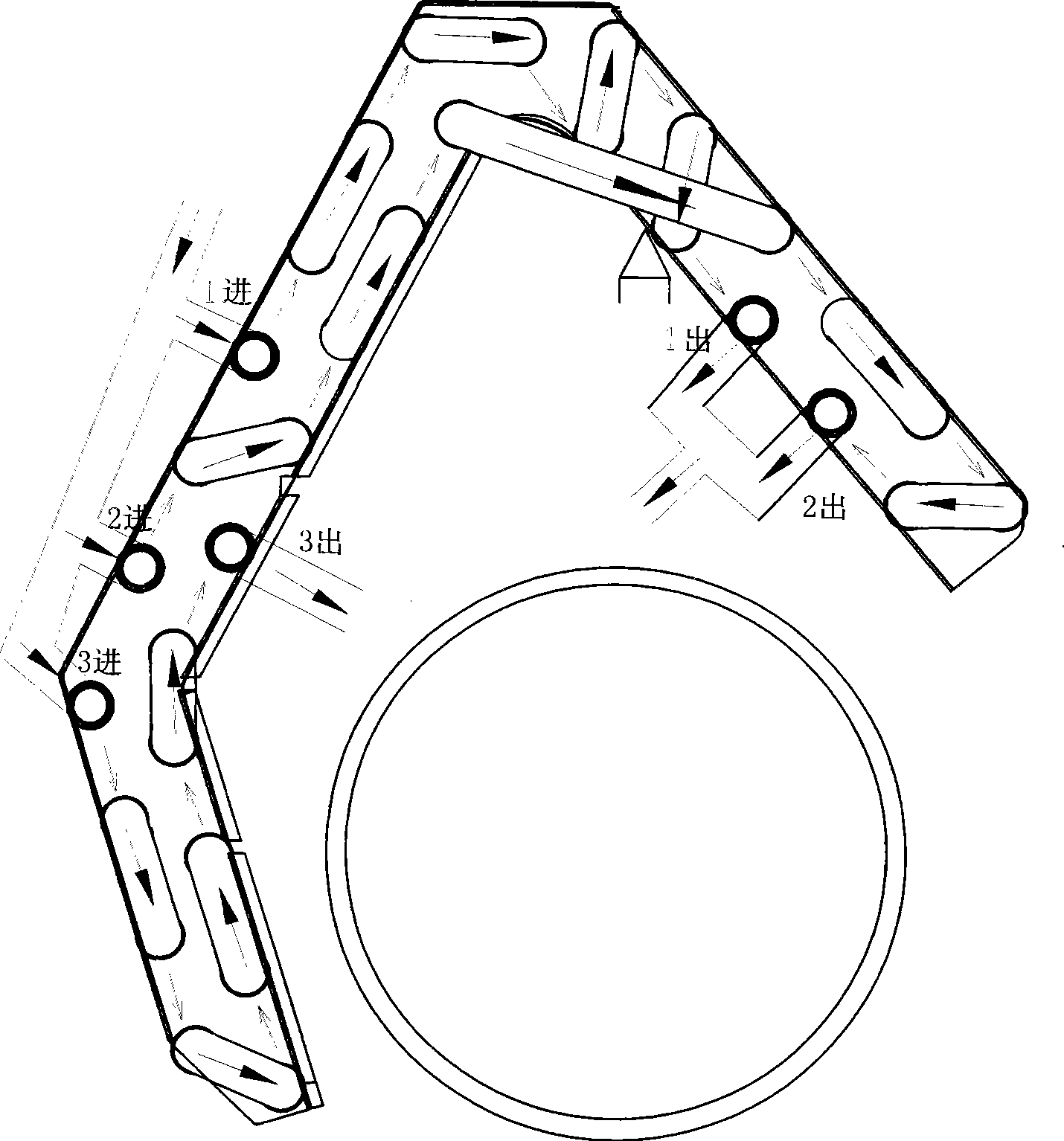

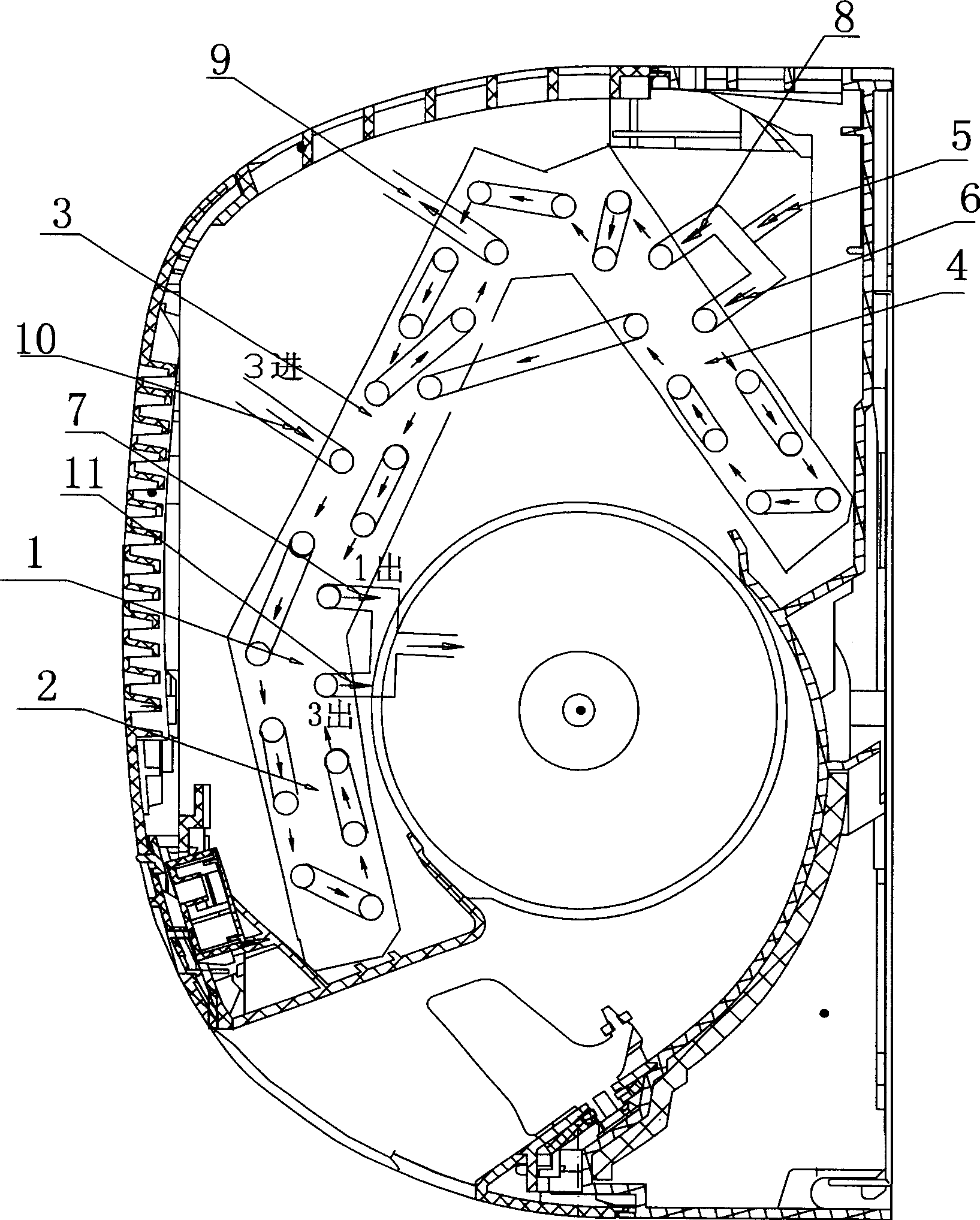

[0012] like image 3 As shown, a high-efficiency air-conditioning heat exchanger 1, when the refrigerant enters the high-efficiency air-conditioning heat exchanger 1, it is divided into three paths, the first path of refrigerant enters from the middle position 6 of the third fold 4 of the heat exchanger, Walk two U-tubes and then go up two U-tubes, jump to the middle of the second fold 3 of the heat exchanger, walk two U-tubes and come out from the first outlet 7 of the heat exchanger. The second route of refrigerant also enters from the middle position 8 of the third fold 4 of the heat exchanger, walks up the distance of one and a half U tubes, and then walks to the second fold 3 of the adjacent heat exchanger to the top of the heat exchanger 1 , and then go down 2 U tubes, and then turn back 1 U tube and come out from the second exit 9. The third fold 4 of the heat exchanger is all on the evaporation temperature like this. The third refrigerant enters from the middle posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com