Double semilunar split collecting and distributing tube for automotive parallel flow evaporator

A shunt tube and parallel flow technology, which is applied in the field of double-half-moon split-type collecting and shunting tubes, can solve the problems of affecting the heat transfer performance of the heat exchanger and poor flow distribution uniformity, and achieves improved flow distribution uniformity, uniform flow distribution, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

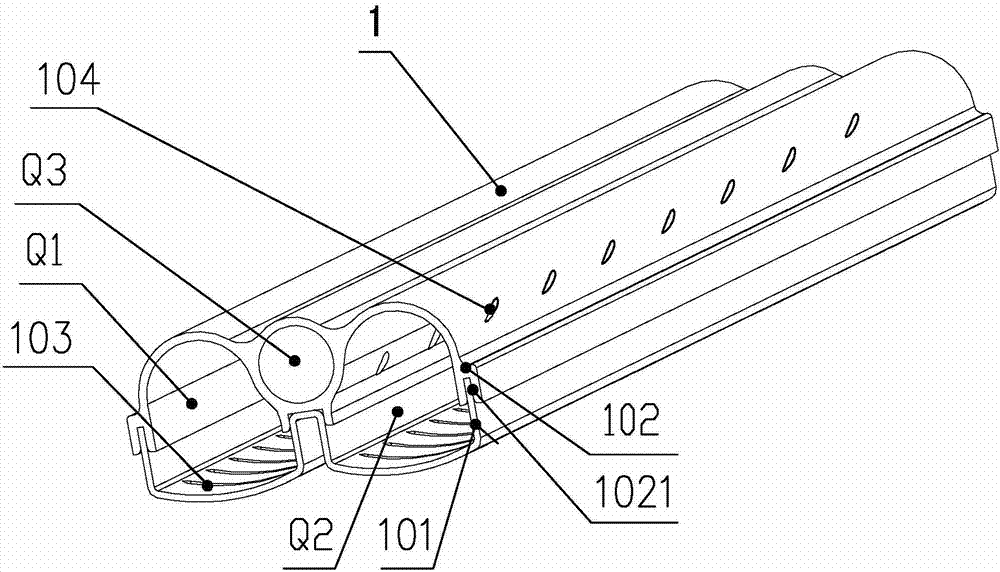

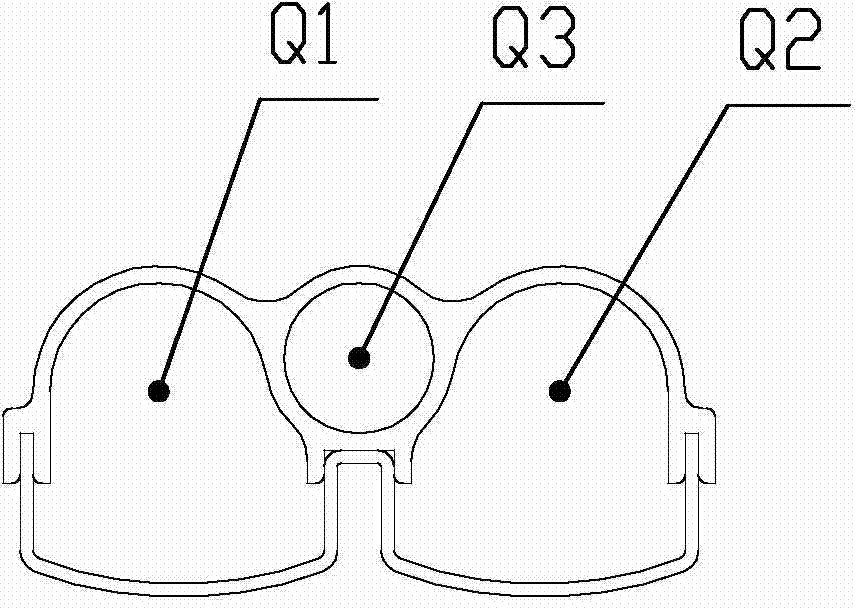

[0024] Figure 1-Figure 2 Disclosed in is a double-half-moon split-type collecting and distributing tube of a parallel flow evaporator for vehicles, which includes a tube body 1, which is formed by connecting the outer plate 102 of the collecting and distributing tube and the inner plate 101 of the collecting and distributing tube. The outer plate 102 of the collecting and distributing pipe is made of a composite aluminum plate, and the outer plate 102 of the collecting and distributing pipe is provided with two half-moon-shaped convex cavities along the axial direction; the inner plate 101 of the collecting and distributing pipe is made of profiles, the inner plate 101 of the collecting and distributing pipe There are two half-moon-shaped concave cavities along the axial direction, and the combination of the two half-moon-shaped convex cavities and the two half-moon-shaped concave cavities forms two independent inner cavities: the first manifold Q1 and the second manifold Q2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com