Transverse reciprocating heating system of coke oven

A heating system and coke oven technology, which is applied in the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc., can solve the problems of difficult air flow balance, difficult temperature control and adjustment, uneven heating temperature, etc., and achieve uniform distribution , saving investment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

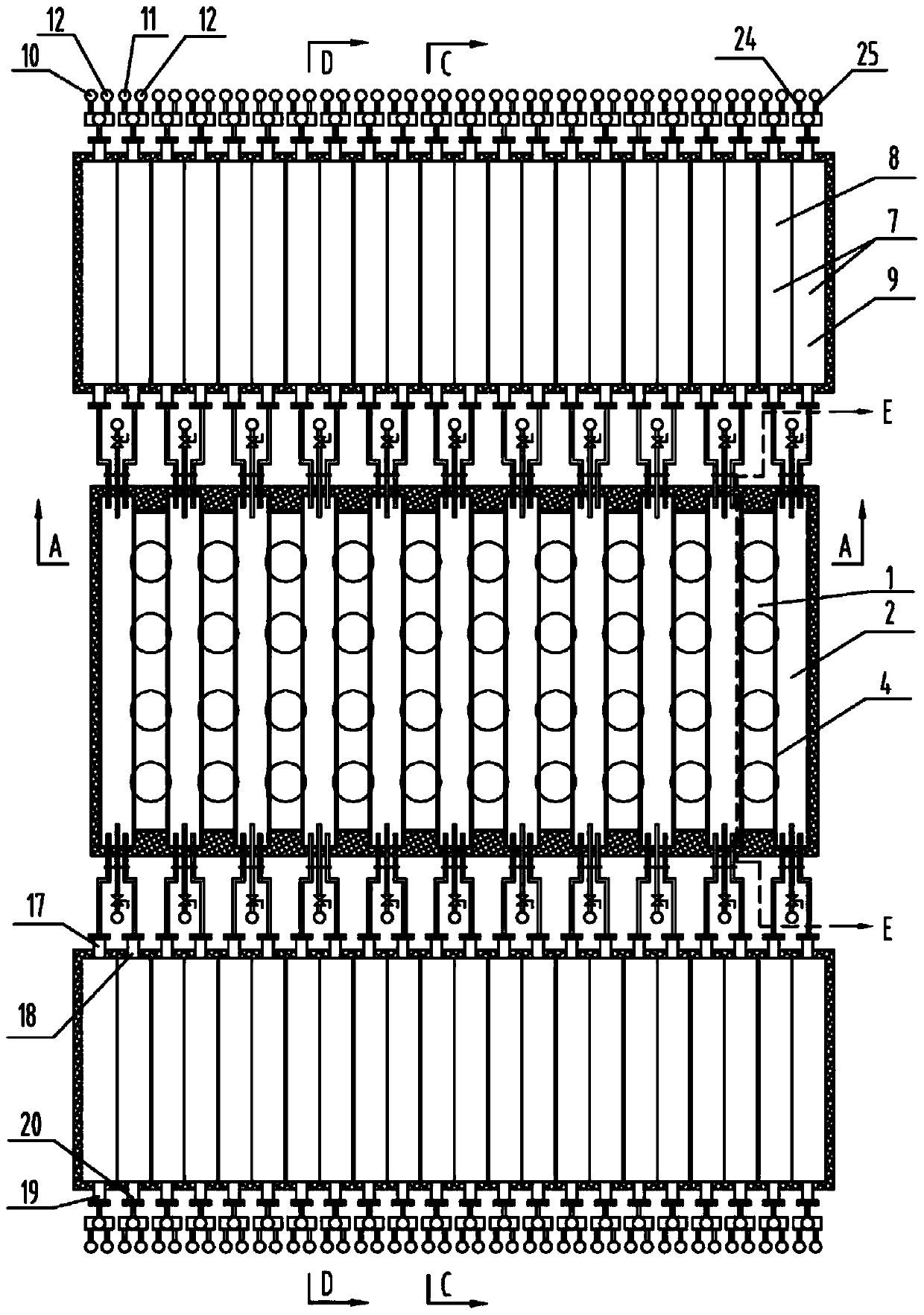

[0029] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

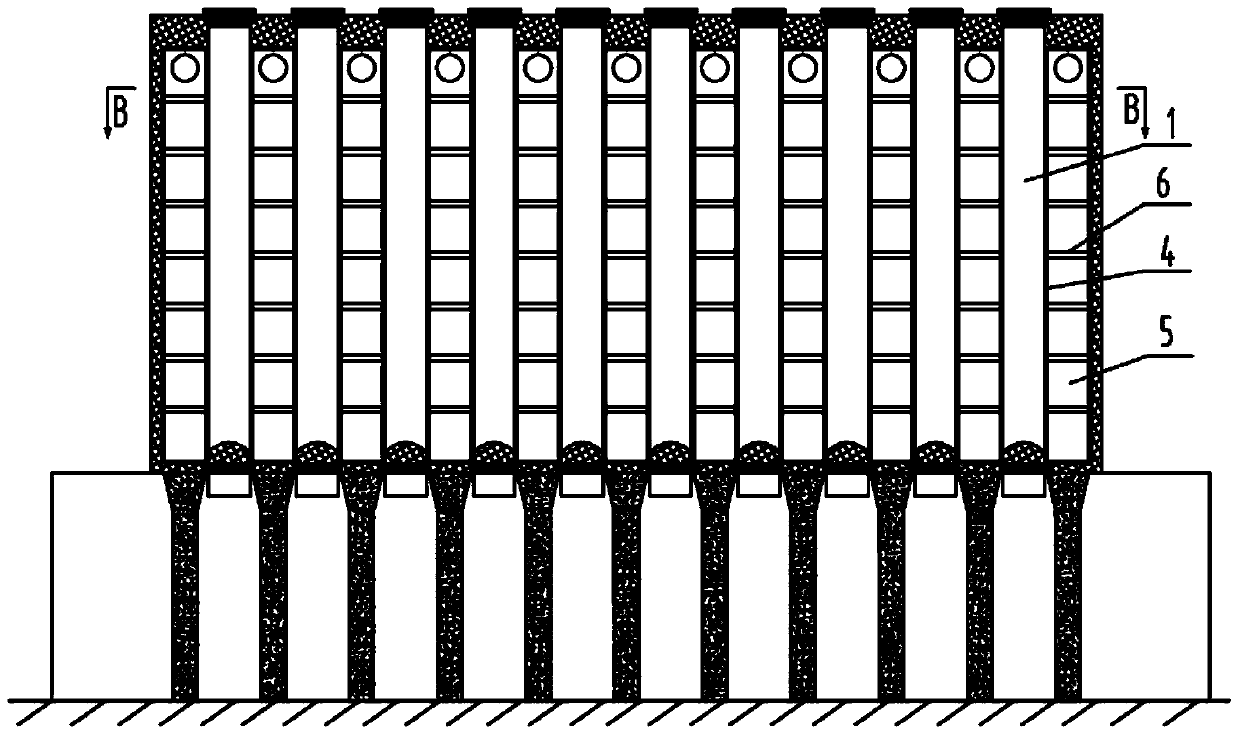

[0030] The transverse reciprocating heating system of the coke oven of the present invention is characterized in that it includes a combustion chamber 2 spaced apart from the carbonization chamber 1, and the combustion chamber 2 is made of silica bricks in a cuboid shape;

[0031] A plurality of horizontal fire channels 5 are arranged up and down inside each combustion chamber 2, and each horizontal fire channel is separated by partition bricks 6, and lean gas / flue gas ports are respectively provided at both ends of each horizontal fire channel 14 and air / flue gas port 15,

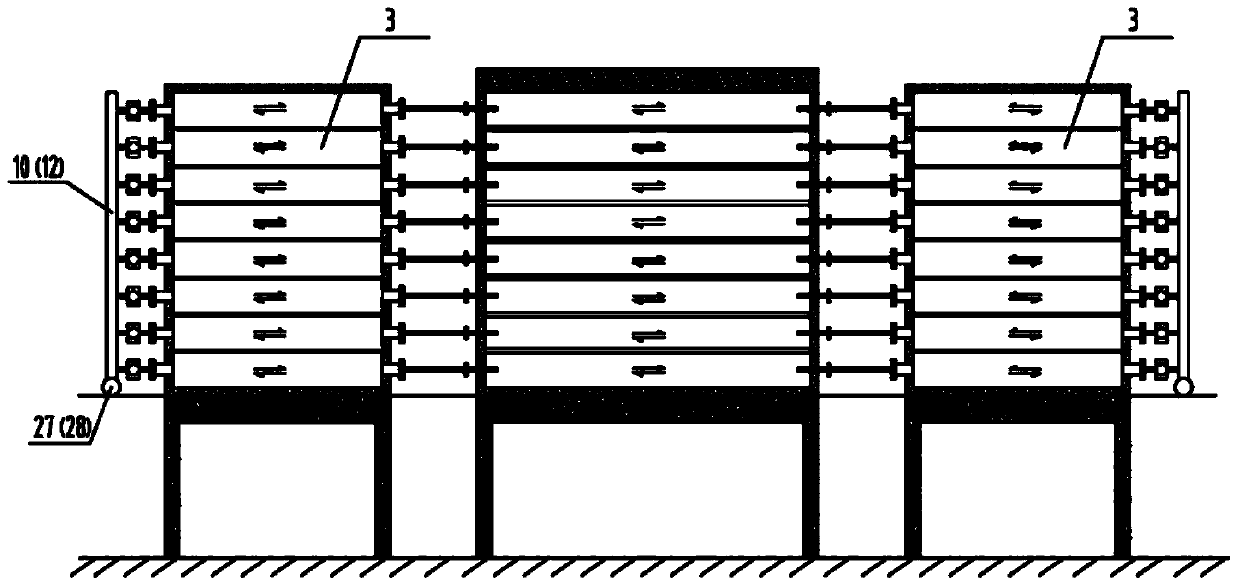

[0032] The regenerator 3 is placed on both sides of the combustion chamber 2;

[0033] The interior of each regenerator 3 is divided into a plurality of heat exchange channels 7 up and down. The number of heat exchange channels 7 is the same as that of the combustion chamber horizontal fire ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com