Ingredient preparation device of water-based nano anti-fingerprint coating

A preparation device and anti-fingerprint technology, which is applied to mixers with rotating stirring devices, mixer accessories, dissolution, etc., can solve problems such as increased labor costs, wrong order of step-by-step feeding, cumbersome feeding and easy confusion, etc., to achieve reduction Manpower and production costs, improving uniformity and quality, and avoiding the effects of disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

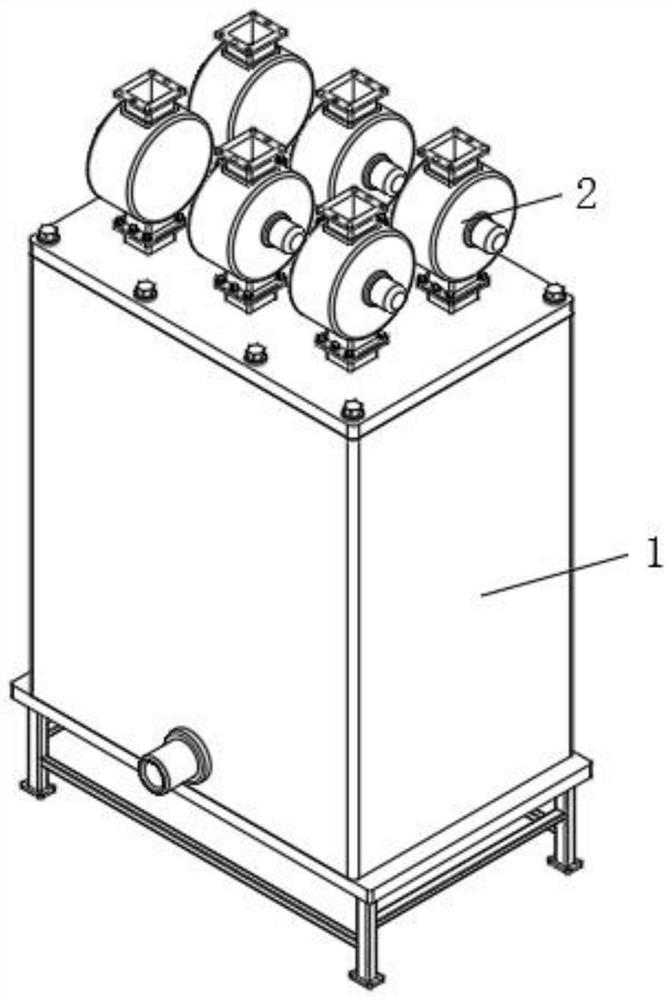

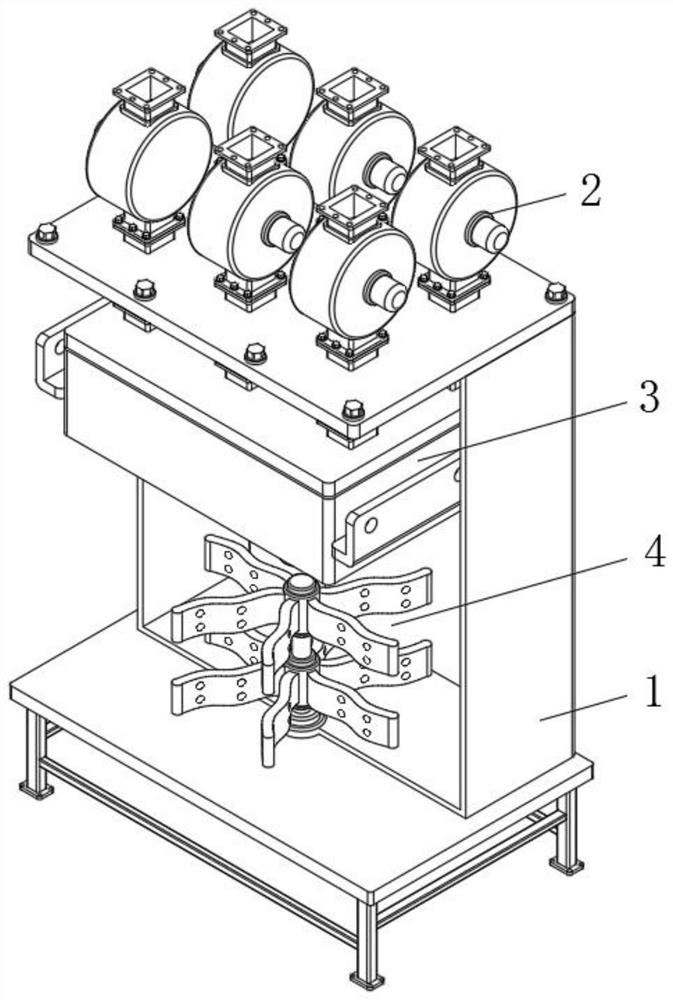

[0037] Figure 1-10 It is an embodiment of the present invention: a batching preparation device of a water-based nano-anti-fingerprint paint, including a cabinet 1, the top of the cabinet 1 is provided with a plurality of feeding mechanisms 2 that automatically execute batches of individual batching, and the inside of the cabinet 1 There is a pre-mixing mechanism 3 for the initial mixing of raw materials, and a stirring mechanism 4 for uniformly mixing the ingredients is provided in the cabinet 1, and the stirring mechanism 4 is located below the pre-mixing mechanism 3. The present invention achieves anti-fingerprint for water-based nano The purpose of automatically controlling the batching of ingredients in paint batching can realize the batch feeding operation of various powder raw materials according to the configuration standards, which not only reduces manpower and production costs, but also has the function of intelligent control of which raw materials to put in each step...

Embodiment 2

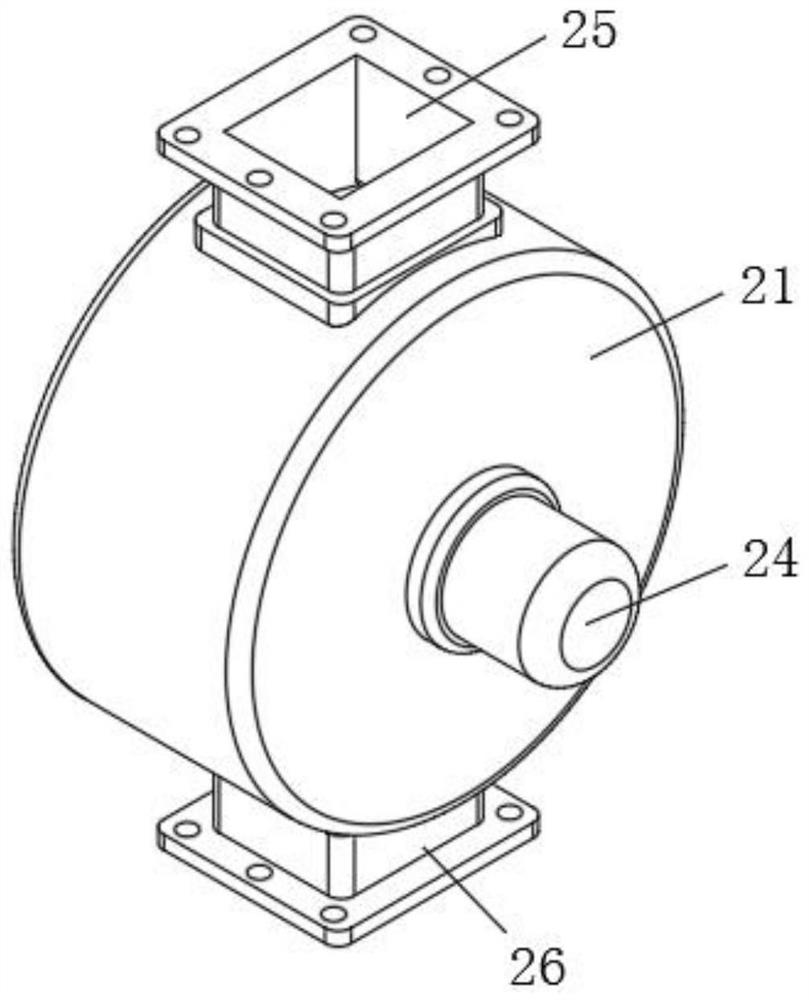

[0045] The end of the material control plate 231 is provided with a closing assembly 233 that is in contact with the inner wall of the housing 21. The closing assembly 233 includes a movable cavity 2331 opened on the end of the material control plate 231, and an extension plate 2332 is movably inserted into the movable cavity 2331. , the inside of the movable chamber 2331 is provided with a spring 2333 acting on the extension plate 2332, the end of the extension plate 2332 away from the material control plate 231 is fixedly connected with a closed end plate 2334, and the end of the closed end plate 2334 is provided with a The contact portion 2335 of the overlapping wall, the two ends of the spring 2333 are respectively fixedly connected with the extension plate 2332 and the opposite side of the inner wall of the movable cavity 2331, the extension plate 2332 is T-shaped, and the contact portion 2335 is set at the end of the closed end plate 2334 The arc structure on the upper pa...

Embodiment 3

[0048] The stirring blade 42 is provided with a drainage hole 44, which can be used in conjunction with the drainage hole 44 on the stirring blade 42, so that the stirring blade 42 can reduce the resistance caused by the solvent when the stirring blade 42 moves in the axial direction, and at the same time provide dredging for the mixing of the solvent and the powder. function, thereby reducing the phenomenon of powder agglomeration and improving mixing efficiency.

[0049] During the operation of the present invention, the external feeding device communicates with the storage containers of various ingredients, and the feeding end communicates with the feeding end 25. When feeding in batches, the servo motor 24 runs to drive the main shaft 22 Rotate, at the same time the material control assembly 23 on the main shaft 22 undertakes the ingredients entered by the feed end 25, the material trough 232 on the material control plate 231 carries the ingredients, and at the same time si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com