Sediment detector for filling pile

A technology of detectors and cast-in-situ piles, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of inability to quantify sediment detection, and achieve the effects of quantitative detection of sediment thickness, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in detail below in conjunction with accompanying drawing:

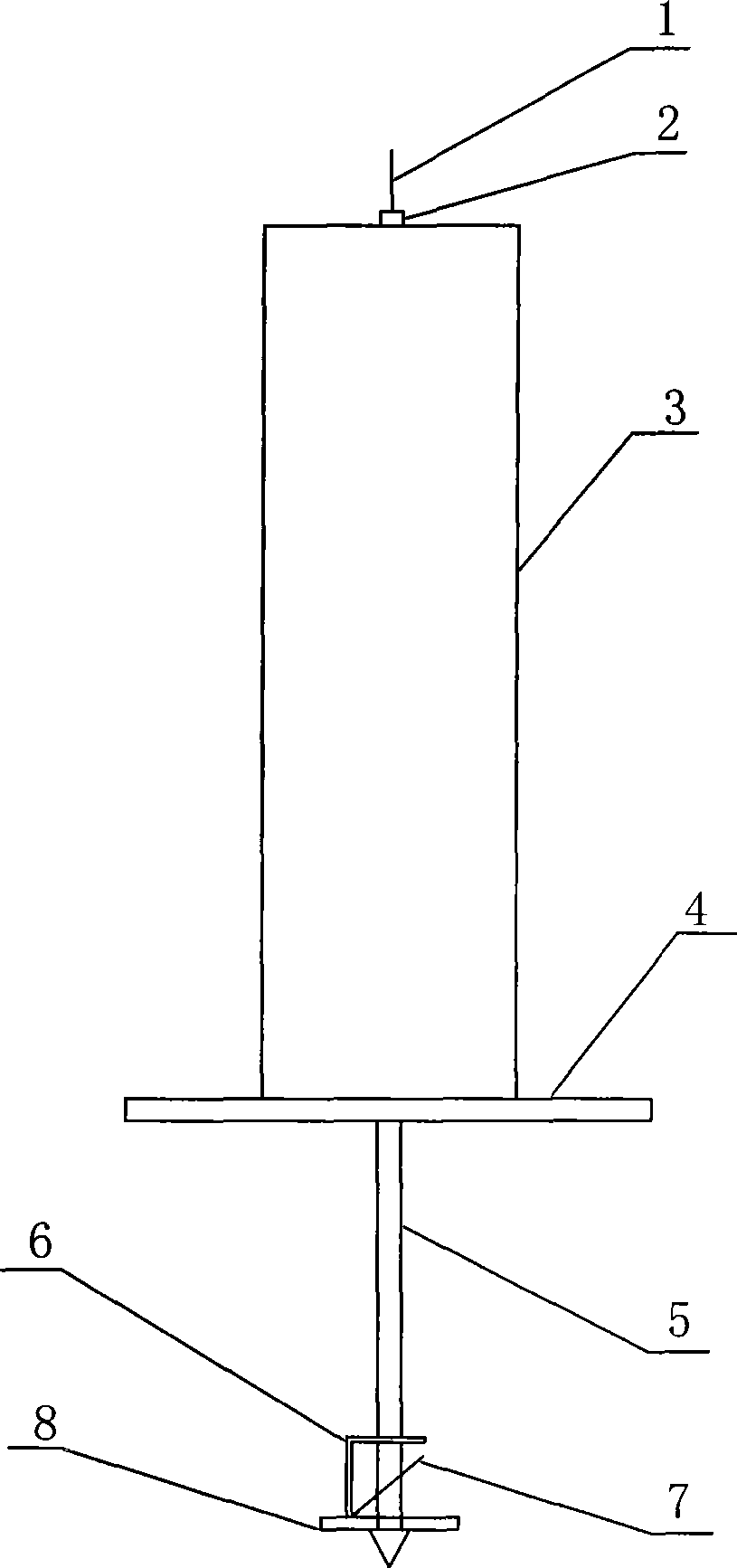

[0009] Such as figure 1 As shown, the present invention includes a suspension rope 1, a lifting lug 2, a counterweight bar 3, a guard plate 4, a probe 5, a guide plate 6, a spring leaf 7, and a one-way plate 8, and the counterweight bar 3 is cylindrical or other shapes The cylindrical weight of the present invention realizes the vertical downward movement of the present invention through the weight of the counterweight bar itself. The upper center of the counterweight bar is provided with a lifting lug 2, and a sling 1 is tied on the lifting lug, and the lower end of the counterweight bar is provided with a There is a guard plate 4, and a probe 5 is arranged under the guard plate. The bottom end of the probe is a conical structure, and the cone top of the conical structure faces downward, which can reduce the resistance when the probe contacts with the sediment at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com