Locking device of cap

A cap clamping and capping technology, which is applied in the direction of capping containers, packaging, capping, etc., can solve the problem of unreliable clamping, clamping teeth and mating teeth that cannot obtain clamping force, and large working hours and cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

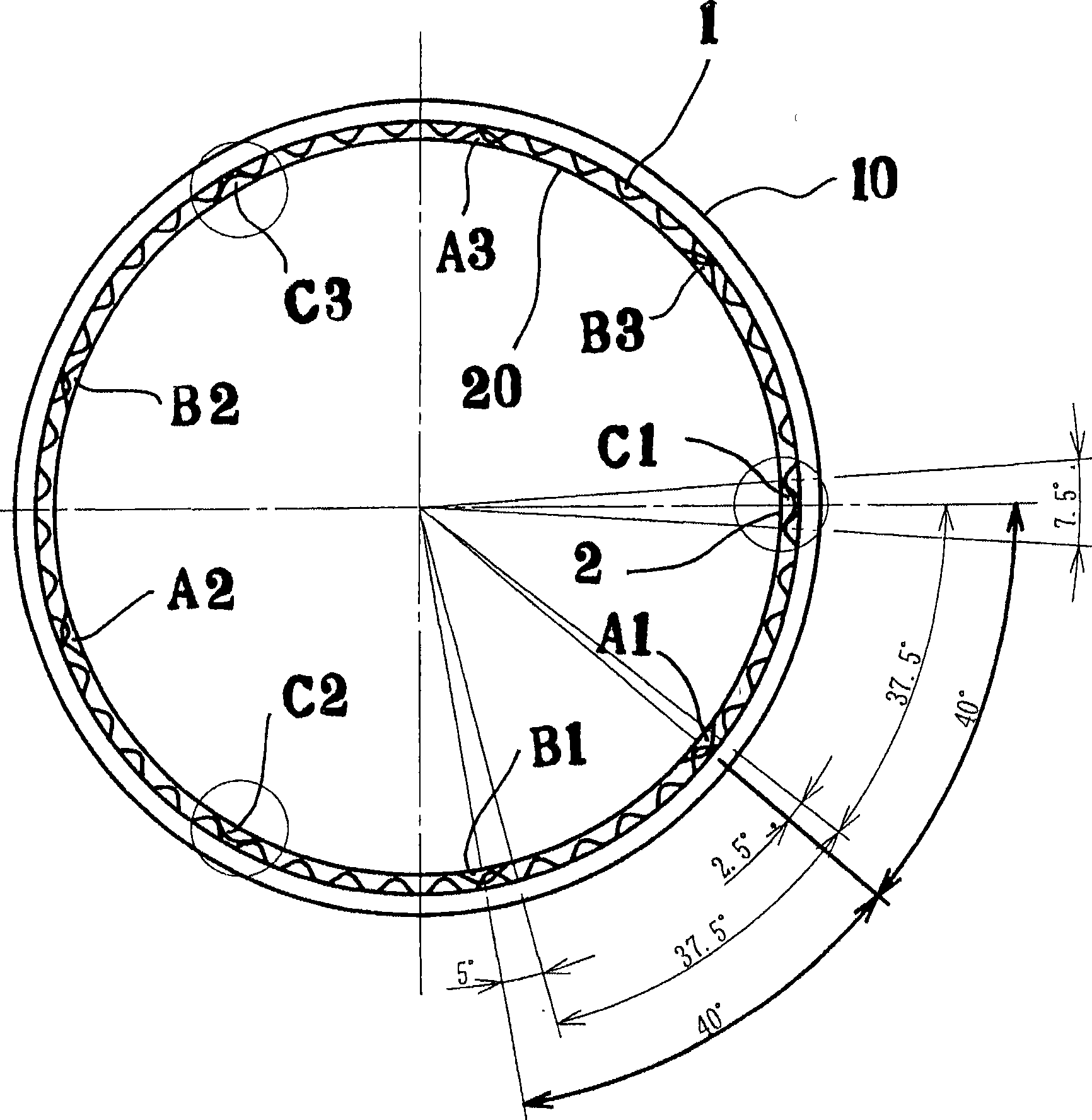

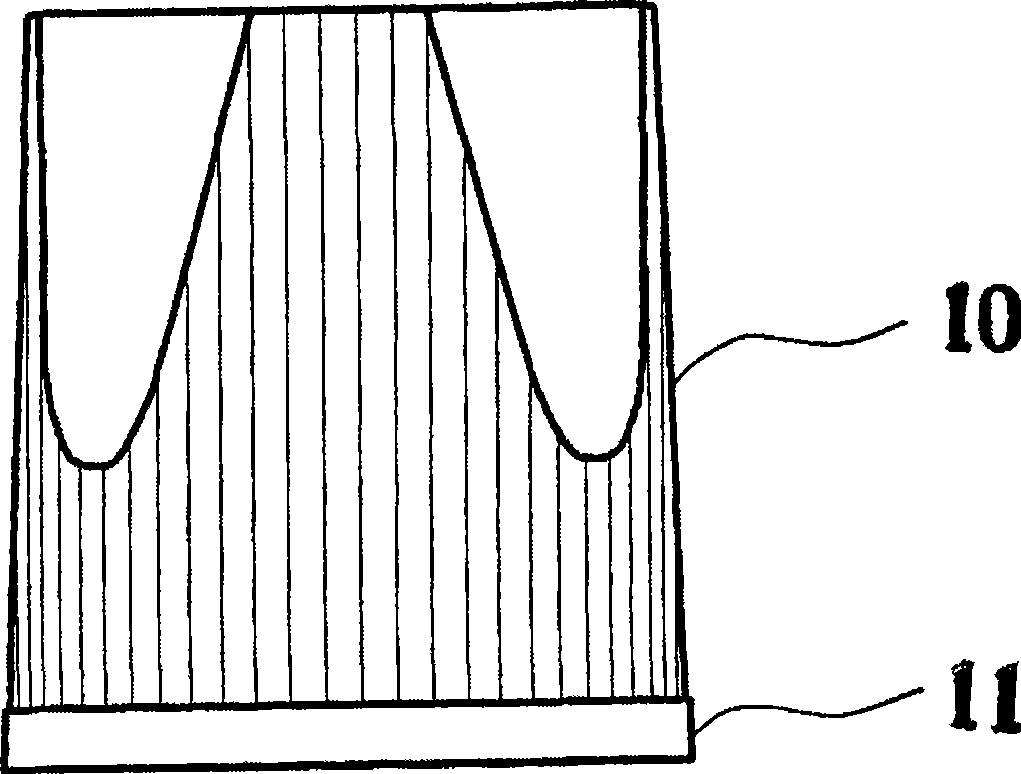

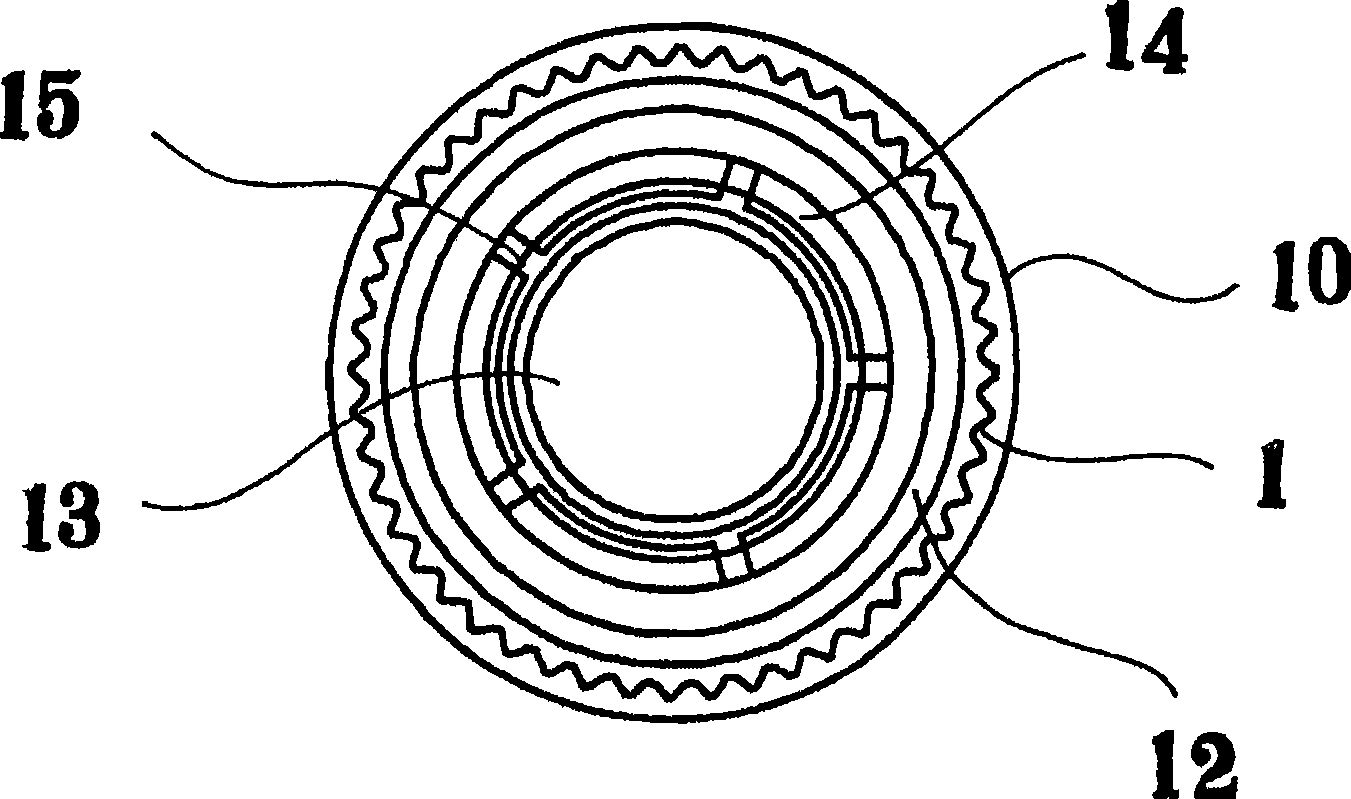

[0072] Figure 11 The cap clamping device of the present invention according to the embodiment has the following structure: when the cap is rotatably mounted to the container, a circumferential mating tooth 1 is provided on either side of the cap and the container, and the clamping tooth 1 provided on the other side is clamped. In the cap clamping device formed by elastically cooperating the tooth 2 with the mating tooth 1, the clamping teeth A, B, C in a group of three are opposite to the central clamping tooth A, and the clamping teeth B, B, C is set to a clamping interval of approximately 1 / 3 pitch P with respect to the 1 pitch P of the mating tooth, so that one of the three snapping teeth A and the adjacent peak and peak of the mating tooth 1 When the center T1 of the valley in the middle cooperates, the other two clamping teeth B and C will contact the inclined surfaces T2 and T3 in the middle of the peak in a balanced manner, so that the mating tooth 1 and the central cl...

Embodiment 2

[0076] In addition, in Figure 12 The cover clamping device has the following structure: three sets of clamping teeth A, B, C are located relative to the central clamping tooth A, and the clamping teeth B and C on both sides are opposite to the first tooth of the mating tooth. The pitch P is set to a clamping interval of approximately 2 / 3 of the pitch P, whereby one A of the three clamping teeth 2 cooperates with the center T1 of the valley between the adjacent peaks and peaks of the mating tooth 1 At the same time, the other two clamping teeth B and C are balanced against the inclined surfaces T2 and T3 in the middle of the peak with elastic force, so that the mating tooth 1 and the central clamping tooth A are close to each other on both sides. Therefore, including the central The clamping teeth A, B, and C of the three groups of clamping teeth are fixedly clamped with the mating tooth 1, so that the cover is kept in a stopped state.

[0077] When one side of the clamping t...

Embodiment 3

[0082] Secondly, in Figure 11 In the embodiment of the above example, among the clamping teeth A, B, and C in groups of three, relative to the clamping tooth A at the center T1, even if the clamping teeth B and C on either side or both sides are set to match the matching teeth 1 The integer multiple of the pitch interval P above 1 pitch is the clamping interval of approximately 1 / 3 pitch interval, which is determined by the Figure 11 The same principle of the embodiment can also obtain the same clamping relationship. Figure 13 In the case of the described embodiment, the cap clamping device of the present invention is set so that when the cap is rotatably mounted to the container, a circumferential mating tooth 1 is provided on either side of the cap and the container, In the cap clamping device in which the provided clamping teeth 2 are elastically matched with the mating teeth 1, a group of three clamping teeth A1, B1, and C1 are located on both sides of the central clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com