Composite transfer method and apparatus for composite transfer paper

A technology for composite transfer and transfer paper, which is applied in the field of composite transfer method and equipment for composite transfer paper, and achieves the effects of avoiding loss and waste, reducing storage and transportation requirements, and compact equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

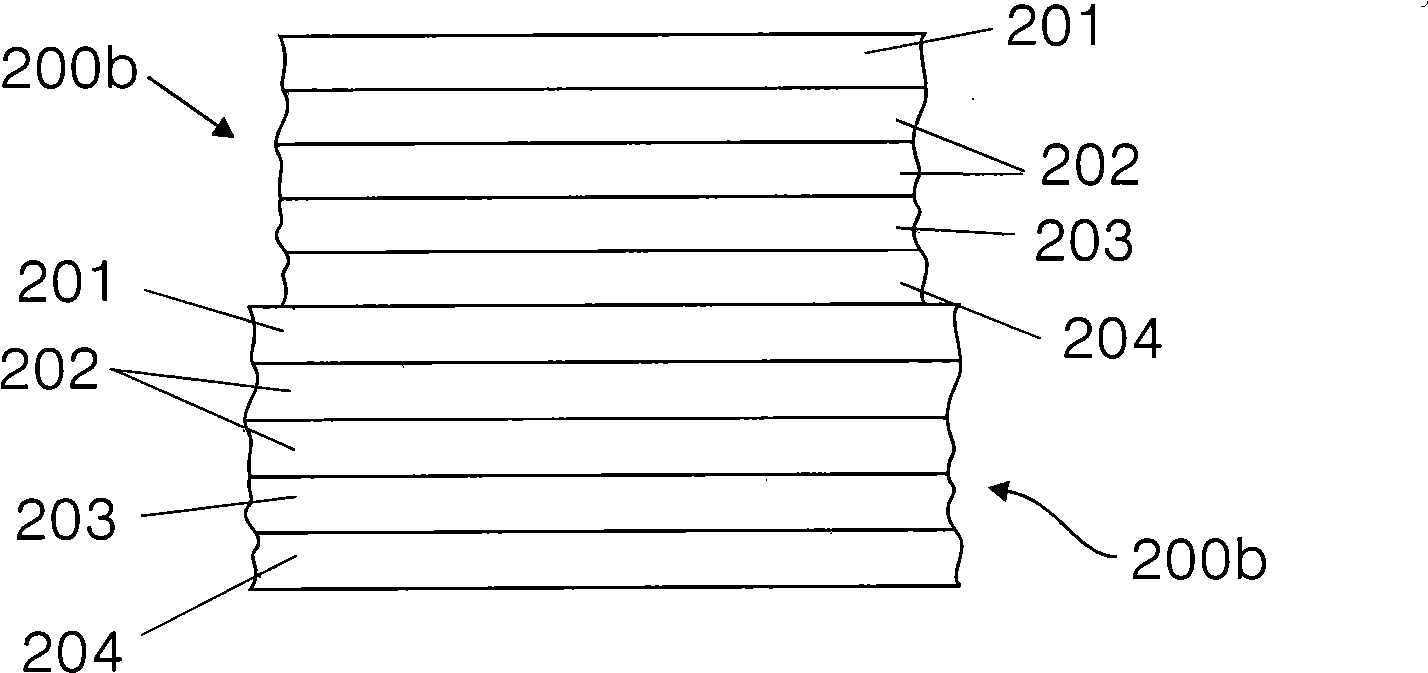

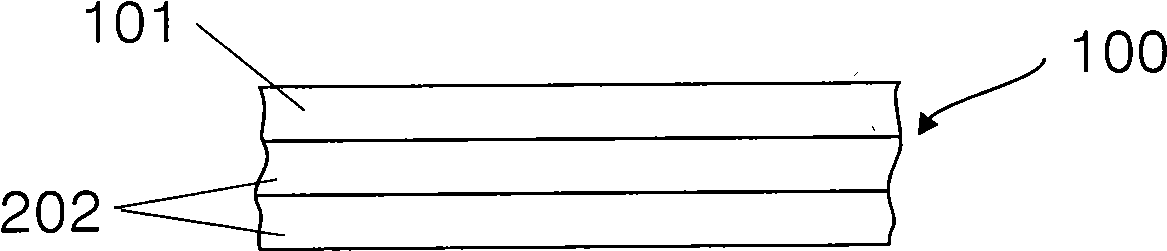

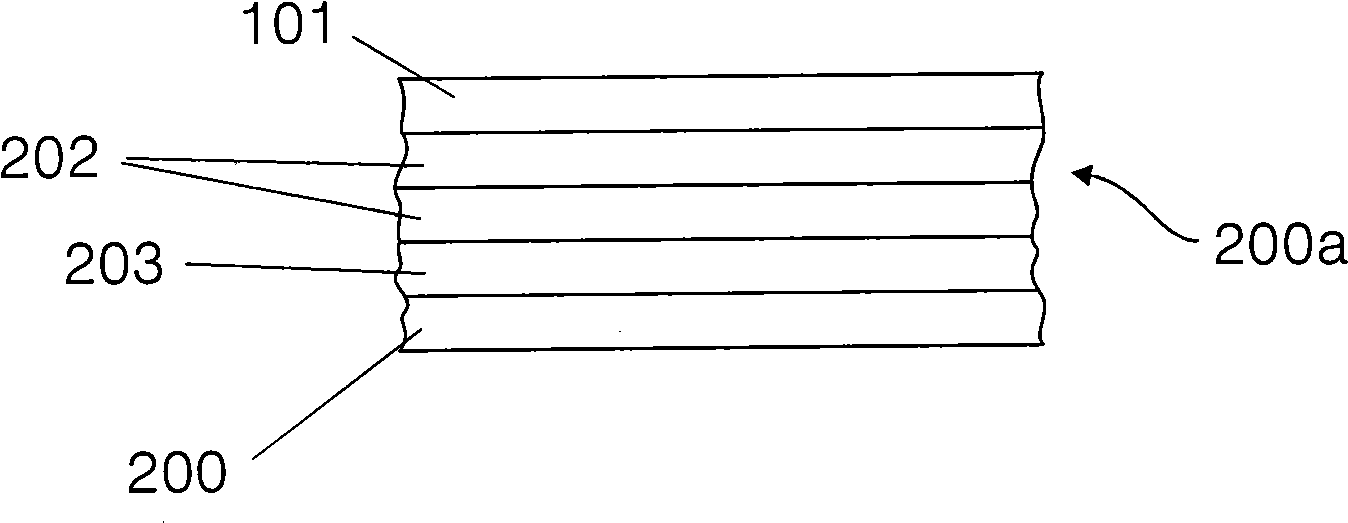

[0031] A composite transfer device for composite transfer paper, such as figure 2 As shown, it includes a frame 1, and also includes a paper unwinding device 10, a film unwinding device 20, a glue coating device 30, a composite device 40, a drying device 50, a peeling device 60, a varnish coating device 70 and a winding device 80 , and along the way a plurality of tension rollers 90 for tension adjustment and large and small cylinders 91, 92 for supporting and transmitting; between the stripping device 60 and the winding device 80, a static eliminator 94 and a cleaning roller 95 are also provided . The drying device 50 is divided into upper and lower layers 51, 52, an exhaust fan 53 is arranged between the upper and lower layers 51, 52, and several quartz heaters are evenly arranged on the upper and lower layers 51, 52. The pipe 54 is equipped with a heating cover 55; a small axial flow fan 56 is arranged between every two adjacent heating covers 55 to ensure that the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com