Fuel injector

一种燃料喷射器、喷嘴体的技术,应用在燃料喷射装置、特殊燃料喷射装置、具有压电元件或磁致伸缩元件的燃料喷射装置等方向,能够解决成本和复杂性影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] In all the drawings, the same reference numerals denote the same features, and for clarity, the reference numerals of the features described in other drawings are omitted.

[0102] In the following description, the terms "up" and "down" are used to denote the directions of the fuel injectors shown in the drawings. However, it is understood that the fuel injectors need not be limited to specific directions in use or other aspects. The terms "upstream" and "downstream" are relative to the direction of fuel flow through the injector from the inlet of the injector to the corresponding outlet.

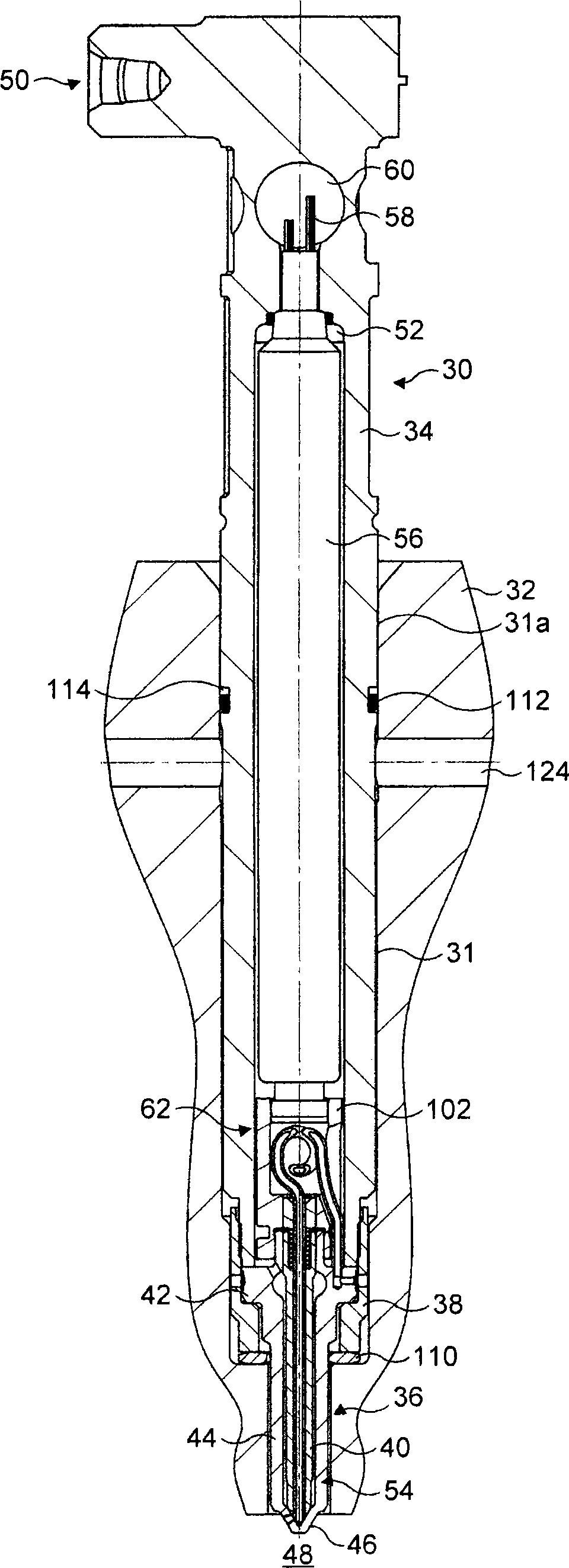

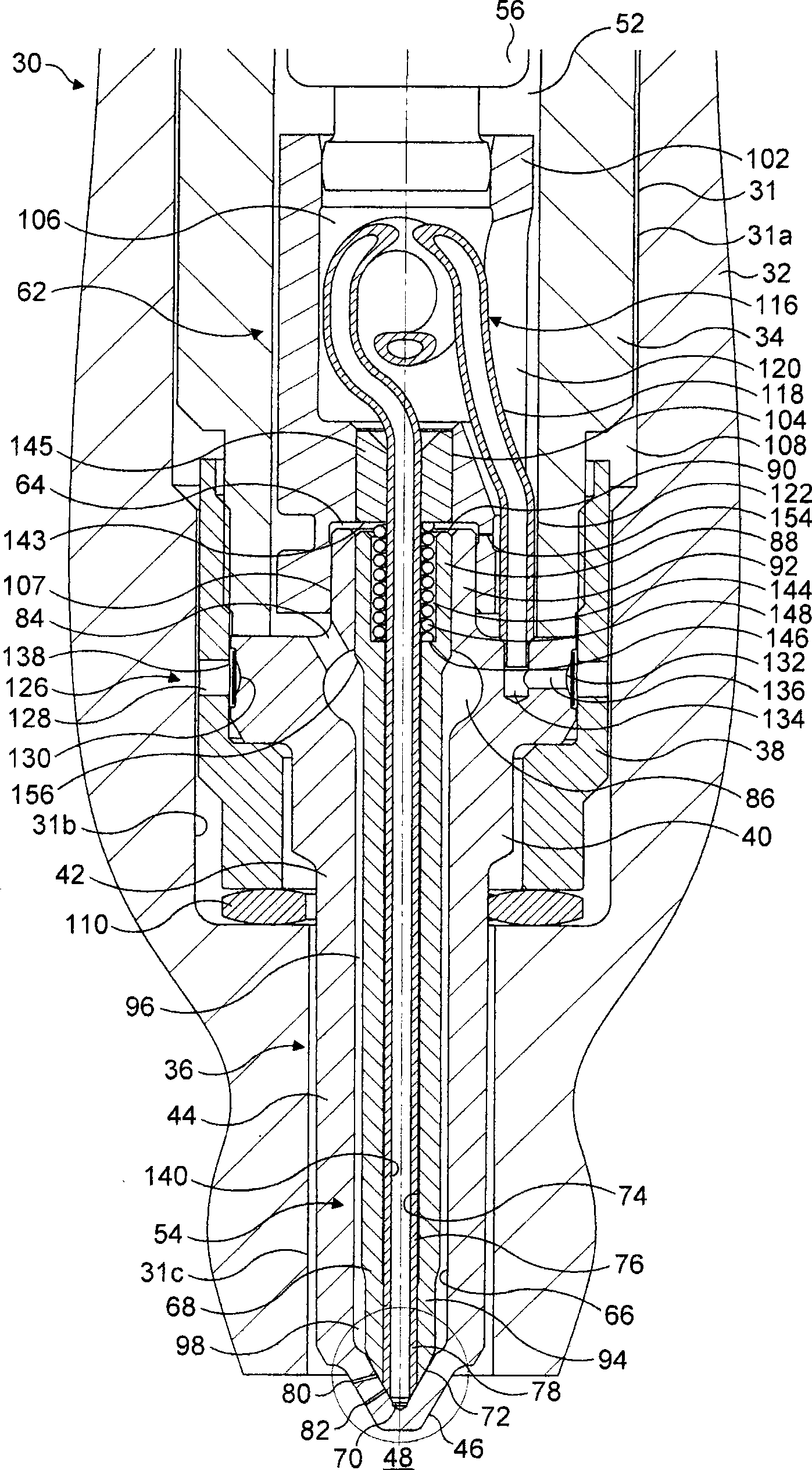

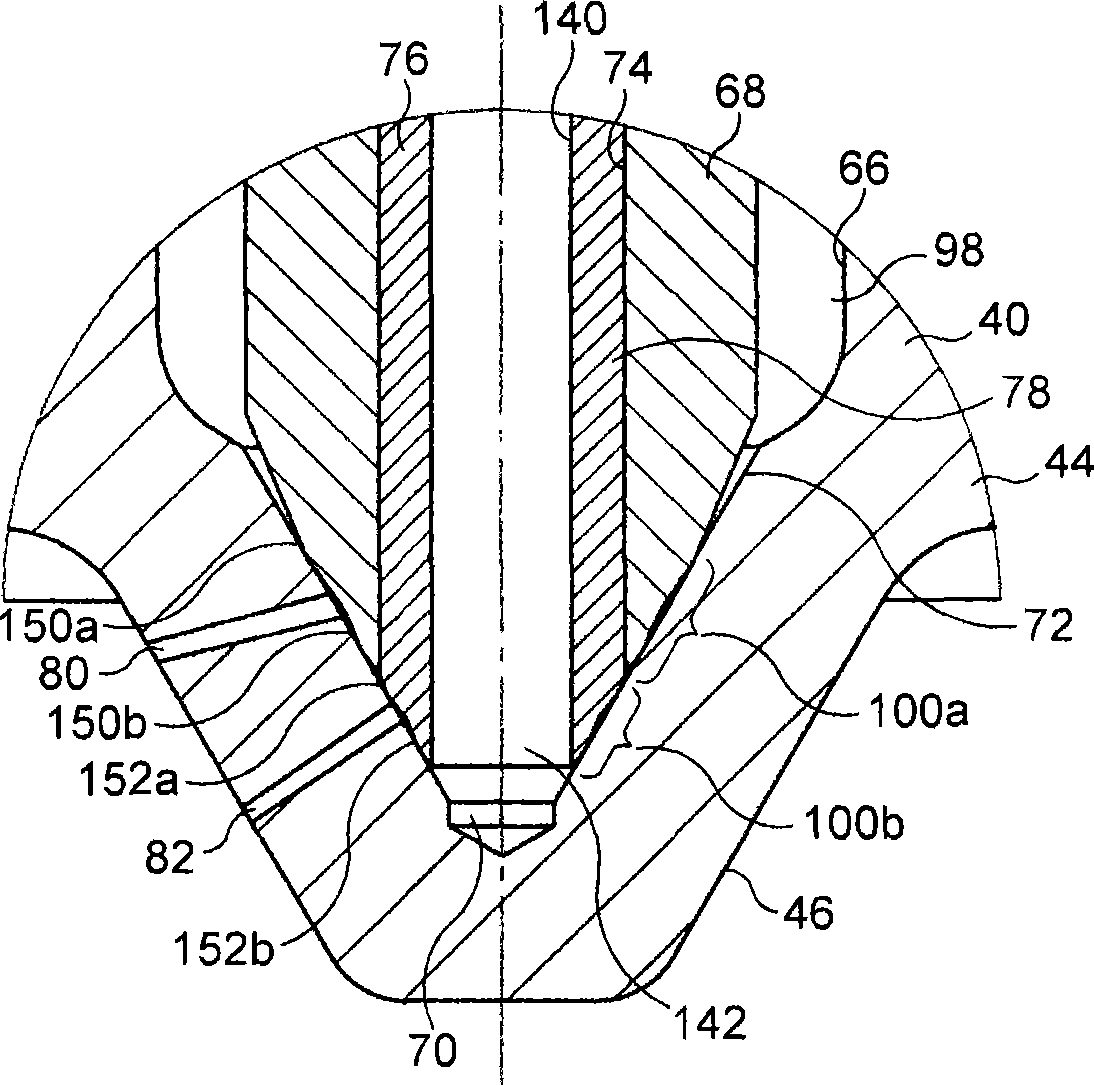

[0103] figure 1 The first embodiment of the fuel injector 30 of the present invention is shown, which is installed in a hole 31 penetrating the cylinder head 32 of an internal combustion engine. The ejector 30 includes an ejector body 34 and an ejector nozzle 36 extending longitudinally.

[0104] The ejector nozzle 36 is fixed to the ejector body 34 by a cap nut 38. Cap nut 38 carries ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com