Fuel injector with divided flowpath nozzle

A fuel injector and flow path technology, applied in fuel injection devices, charging systems, combustion engines, etc., can solve problems such as reduced combustion efficiency, increased emissions, and incomplete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

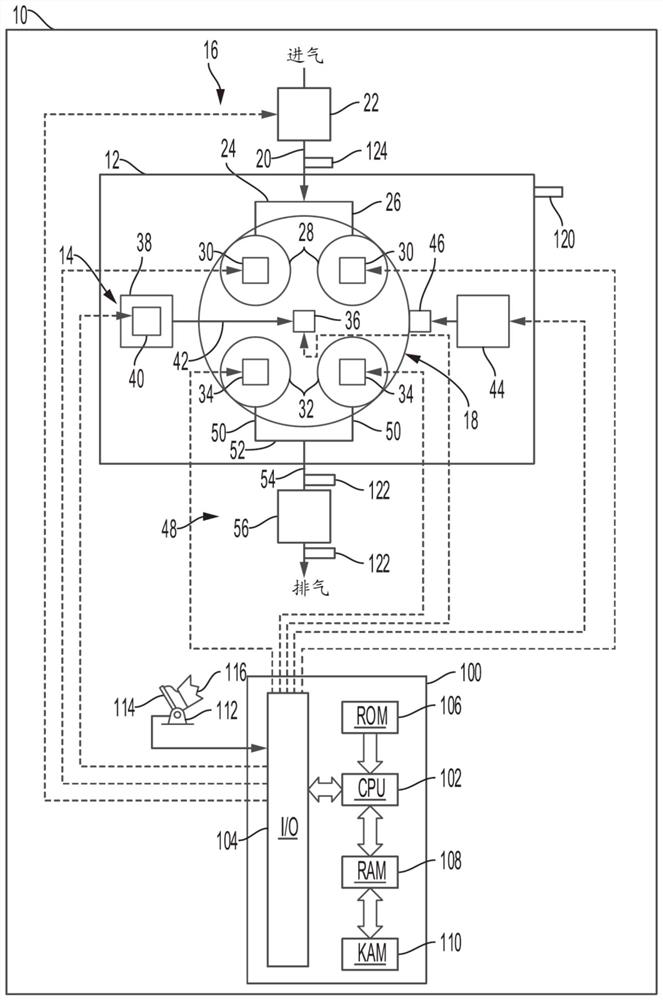

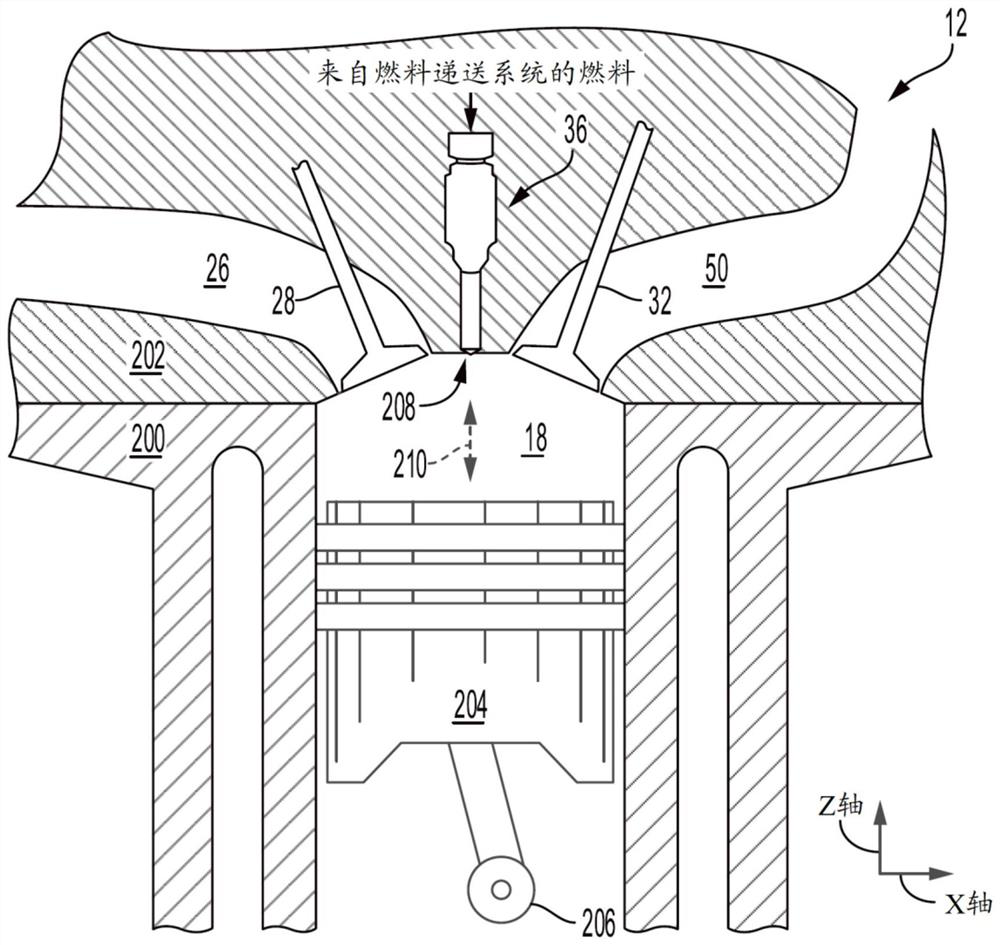

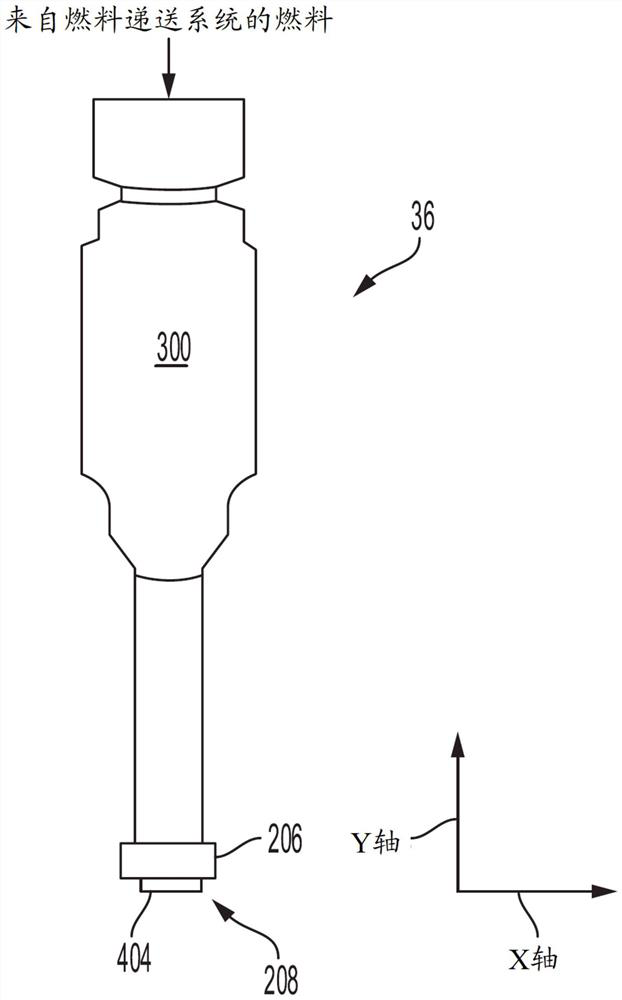

[0025] The following description relates to direct fuel injectors in fuel delivery systems of internal combustion engines. Direct fuel injectors produce a spray pattern that improves fuel atomization and reduces wall wetting. For example, the nozzle may include a divider therein that splits the fuel flow path from the inlet intake side of the nozzle to the outlet exhaust side of the nozzle, thereby providing more outlet orifices for improved fuel distribution and mixing, while Will not compromise the structural integrity of the nozzle.

[0026] Additionally, the internal geometry of the split flow path can be optimized to improve fuel spray characteristics as desired. For example, multiple fuel flow paths may be provided within the nozzle, each fuel flow path being spaced apart from each other and arranged to maximize fuel cavitation through the fuel flow path. Additionally, the cross-sectional shape of the separator, the exit flow path deflection angle, the inlet flow path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com