Full-automatic acquisition method for micro-image of textile fibre longitudinal cutting stock

A textile fiber, fully automatic technology, used in textile testing, material analysis by optical means, measuring devices, etc., can solve the problems of poor accuracy, laborious, time-consuming, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

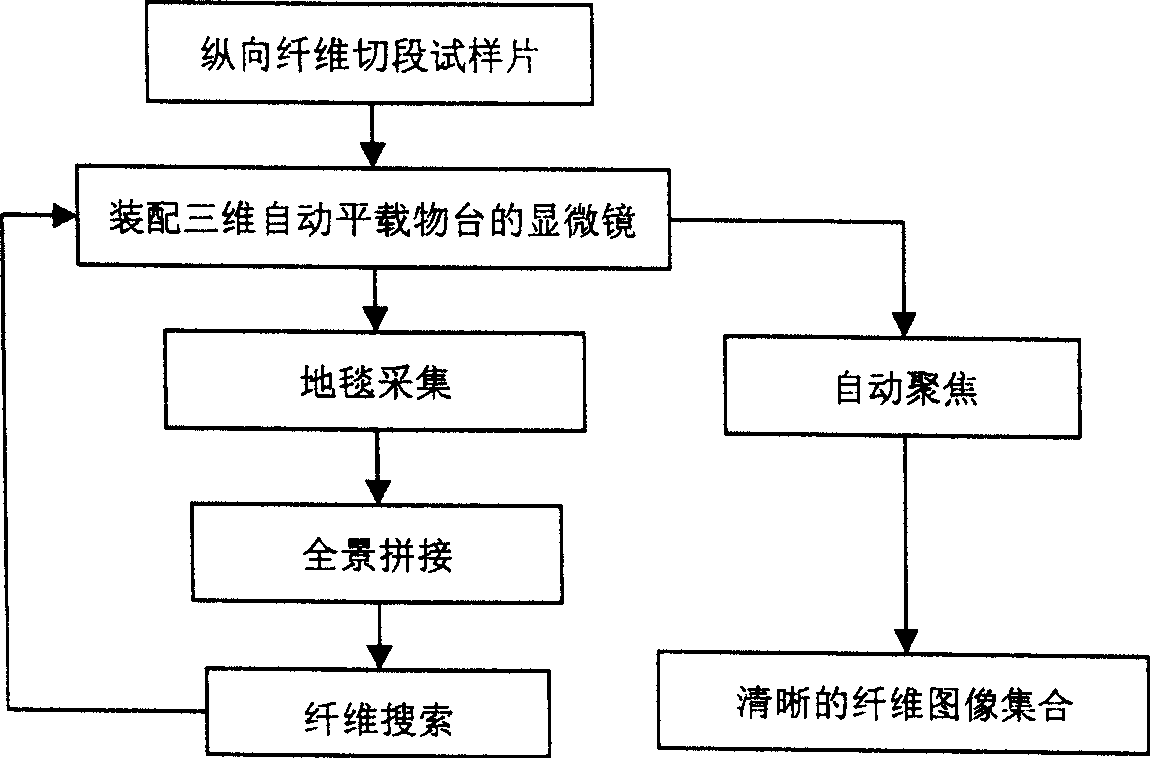

[0023] refer to figure 1 , which is a diagram of the steps of the method for fully automatic shooting and collection of microscopic images of fiber longitudinal sections in the present invention.

[0024] As shown in the figure, it is carried out through the following steps: first "starting from the longitudinal fiber section sample piece", to "microscope equipped with a three-dimensional automatic flat stage", all the way to "automatic focus" to "clear fiber image collection" ; Another way to 'carpet acquisition', 'panoramic stitching', 'fiber search', and then return to 'microscope equipped with three-dimensional automatic flat stage'.

[0025] Automatically search fibers and collect images in the horizontal (X, Y) and vertical (Z) directions, and realize automatic shooting and collection of microscopic images of fiber longitudinal sections.

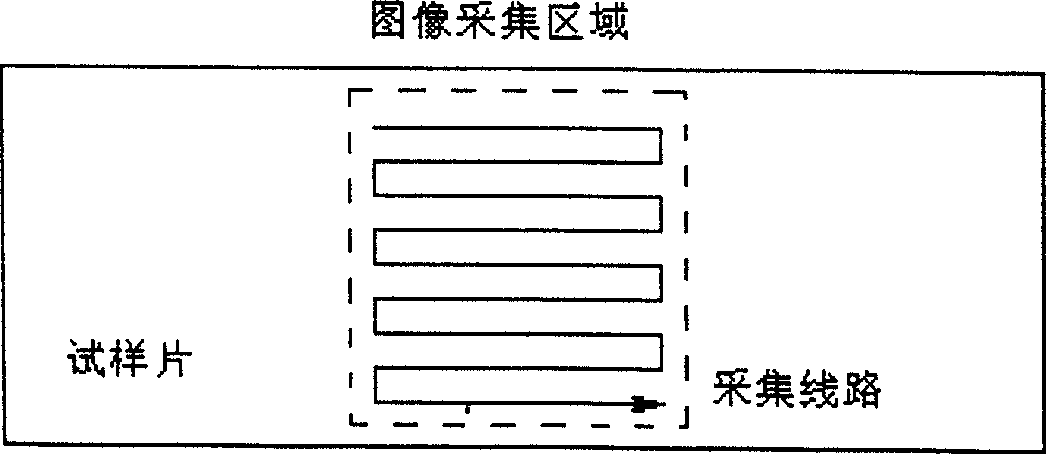

[0026] refer to figure 2 , which is a schematic diagram of carpet collection of longitudinally cut fiber of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com