Lens array, exposure head, and image forming apparatus

A lens array and exposure head technology, applied in the field of lens arrays, can solve the problems of enlarging the lens array and increasing the width of the lens array, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

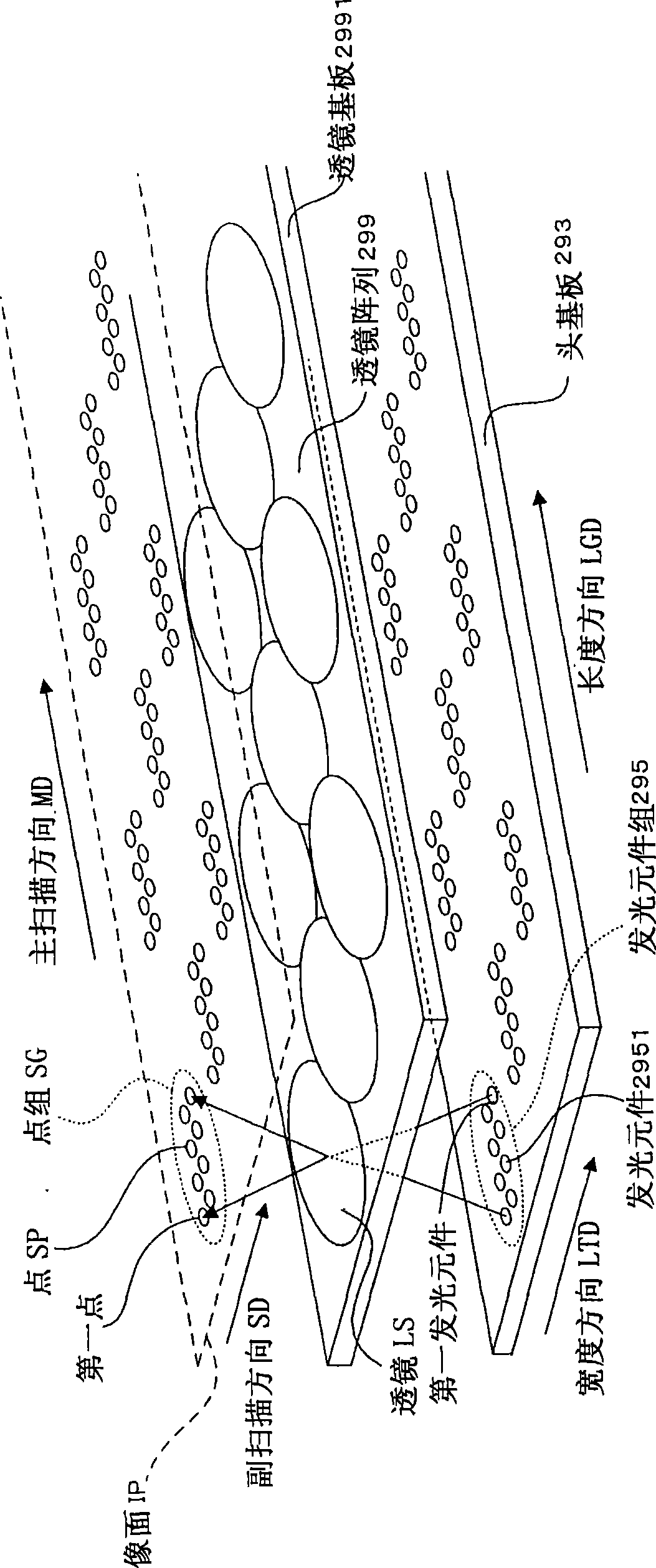

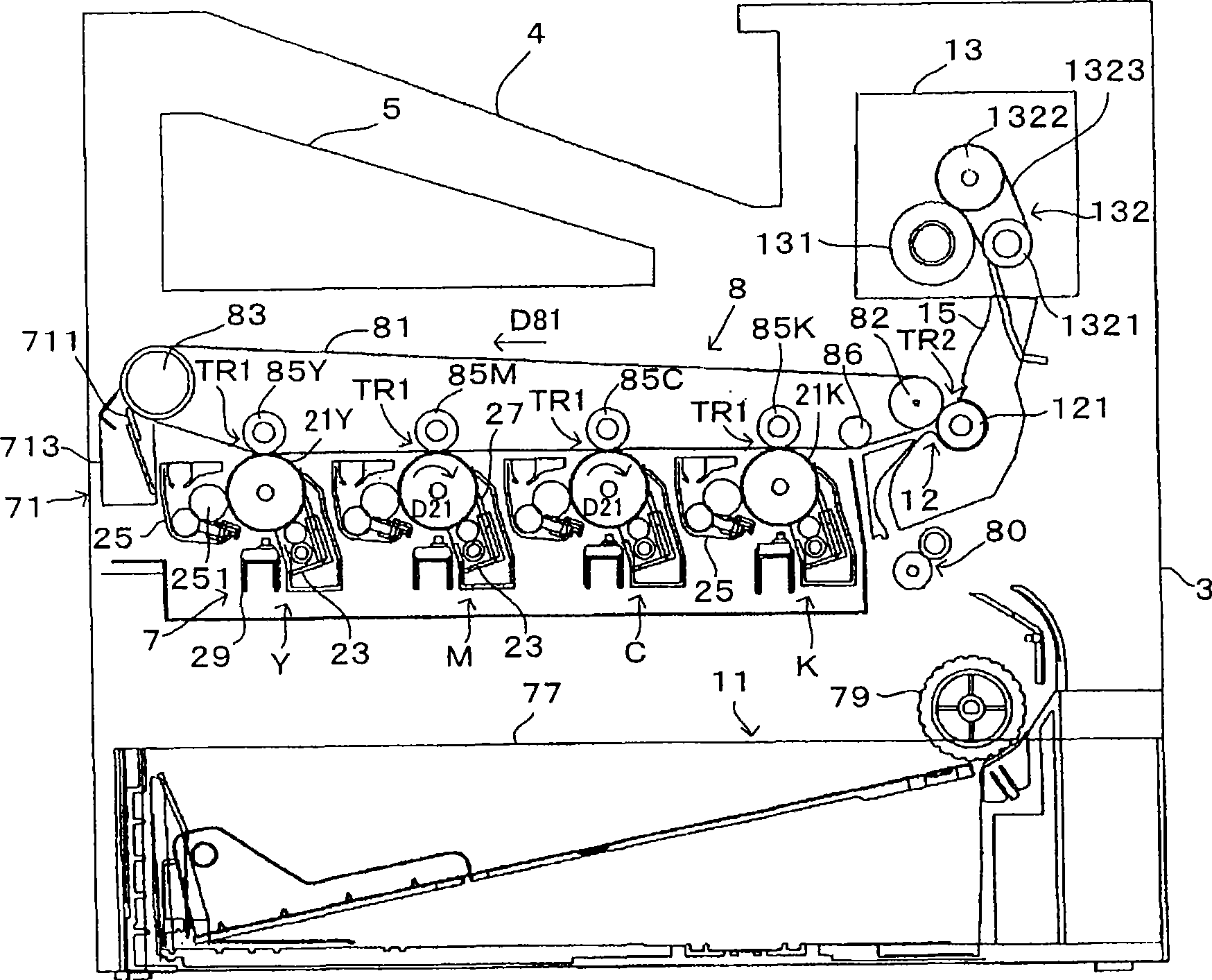

[0072] image 3 It is a diagram showing an example of an image forming apparatus equipped with a line head to which the present invention is applied. also, Figure 4 yes means image 3 A diagram of the electrical structure of the image forming device. This device is an image forming device capable of selectively executing a color mode in which toners of four colors of black (K), cyan (C), magenta (M), and yellow (Y) are superimposed While forming a color image, the monochrome mode forms a monochrome image using only black (K) toner. and, image 3 It is the corresponding drawing when the color mode is executed. In this image forming apparatus, when an image forming command is given from an external device such as a host computer to a main controller MC having a CPU, a memory, etc., the main controller MC sends a control signal, etc. to a motor controller EC, and communicates with the image The video data VD corresponding to the formation command is given to the head contr...

no. 2 approach

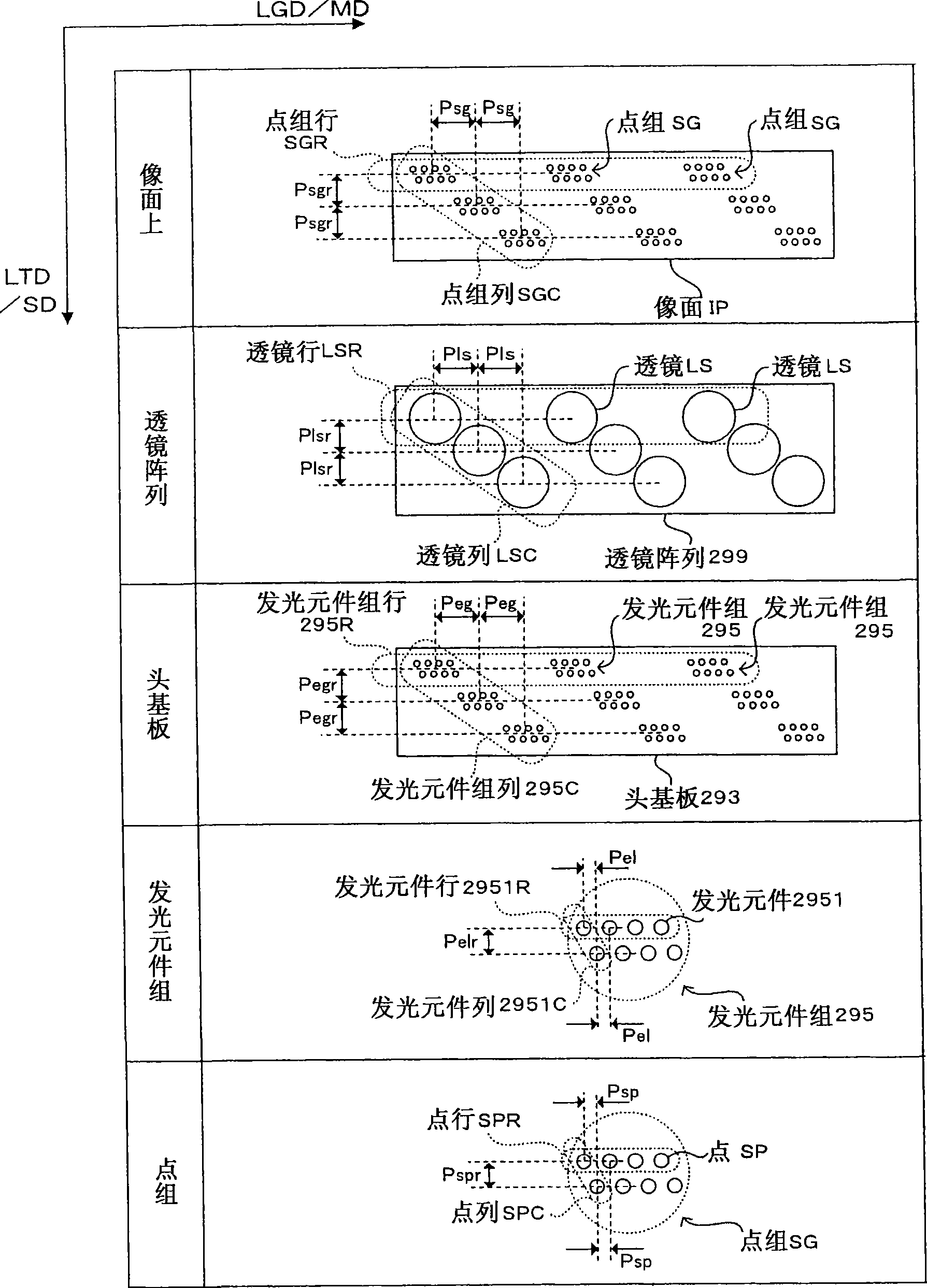

[0117] Figure 13It is a plan view which shows the structure of the lens array which concerns on 2nd Embodiment. The lens array 299 includes a lens array substrate 2991 (light-transmitting substrate) made of glass. In this way, by forming the lens array substrate 2991 from a glass material with a relatively small coefficient of linear expansion, deformation of the lens array 299 due to temperature changes is suppressed. The lens array substrate 2991 has a length W1 in the longitudinal direction LGD, and a width W2 (length W2) in the width direction LTD. In addition, the relationship of length W1>W2 is satisfied, and the lens array substrate 2991 has a long side in the longitudinal direction LGD. On the surface 2991-h of the lens array substrate 2991, a plurality of lenses LS made of photocurable resin (resin material) are formed by the above-mentioned metal mold method. The plurality of lenses LS are two-dimensionally arranged. That is, three lenses LS are arranged in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com