Wire rewinding structure for vehicle denso production open wire machine

A wire-opening machine and electrical equipment technology, applied in the direction of cable installation, cable installation devices, circuits, etc., can solve the problems affecting the factory production environment, affecting the quality of wire products, electrical equipment production, copper core flying wire, etc. Easy to bundle, ensure cleanliness, and prevent the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

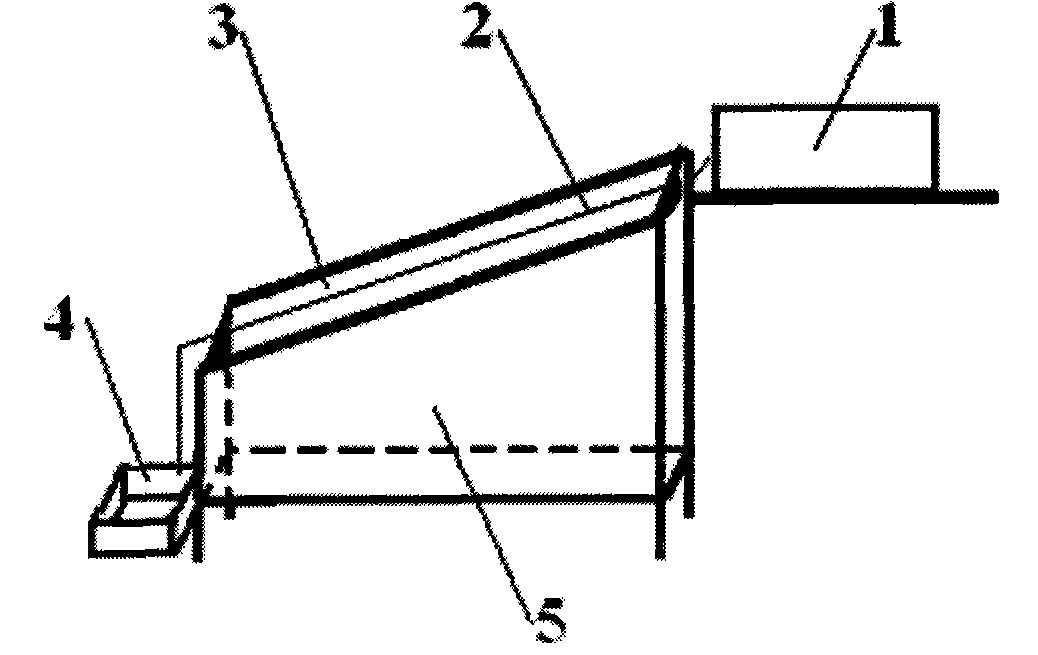

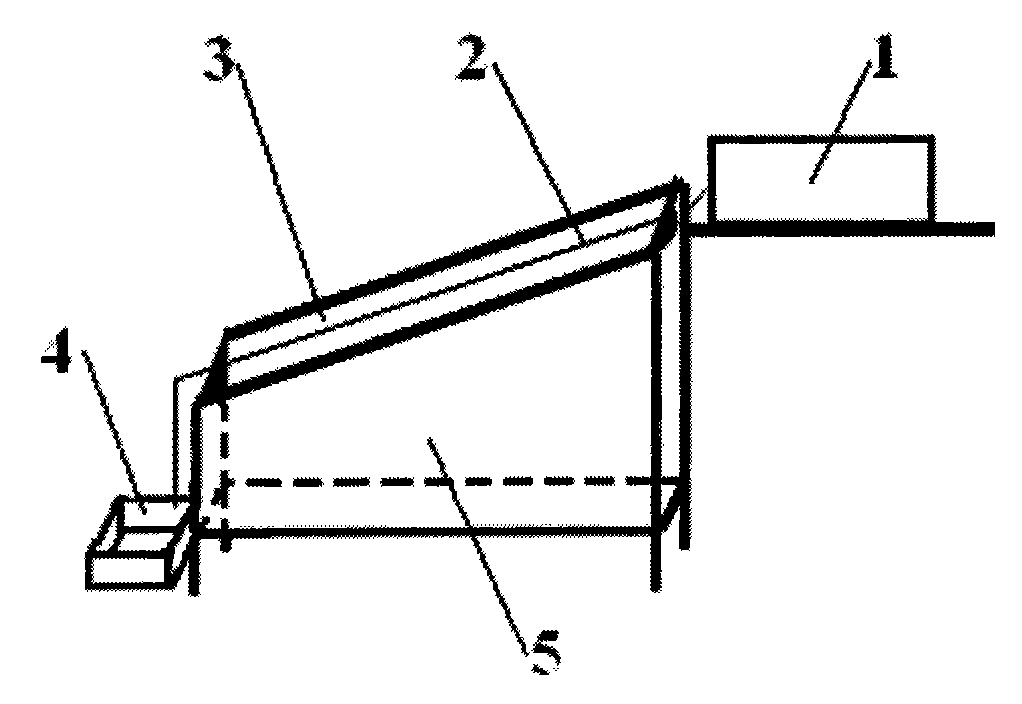

[0024] On the outside of the lower end of the inclined structure of the trapezoidal terminal frame 5, a terminal box 4 is set and placed on the ground, and the wire 2 that slides down from the inclined structure on the upper part of the trapezoidal terminal frame 5 falls into the described Inside junction box 4.

[0025] The present invention places the junction box 4 at the outer low end of the trapezoidal junction frame 5, so that the wires 2 falling from the trapezoidal junction frame 5 can all enter the junction box 4, ensuring that the outgoing lines are neat and the wires do not fall to the ground.

Embodiment 2

[0027] The structure in which the supporting wire 2 slides down on the inclined structure of the present invention is a leather pocket 3, and the two sides of the leather pocket 3 are fixed on the frame body of the trapezoidal wiring frame 5.

[0028] The present invention installs a transparent soft leather pocket on the inclined surface of the top of the trapezoidal wiring frame 5, because the material of the leather pocket 2 is very soft, so that the lead 2 can reduce damage in the process of sliding down.

Embodiment 3

[0030] The leather pocket 3 of the present invention forms a groove, and the opening of the groove is upward, and its length direction is parallel to the direction in which the wire 2 slopes down. The groove structure is adopted to prevent the wire 2 from sliding out to both sides and not falling into the junction box 4 during the sliding process, so that the work is more reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com