A mobile hydrothermal resource treatment device for hazardous waste with high salt and high cod

A resource-based, mobile technology, applied in waste treatment, transportation and packaging, chemical instruments and methods, etc., can solve the problem of small output of hazardous waste, and achieve the goal of keeping the site clean and tidy, the opening and closing method of the flying wing door is stable, and the opening and closing methods are improved. The effect of closing efficiency and opening and closing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

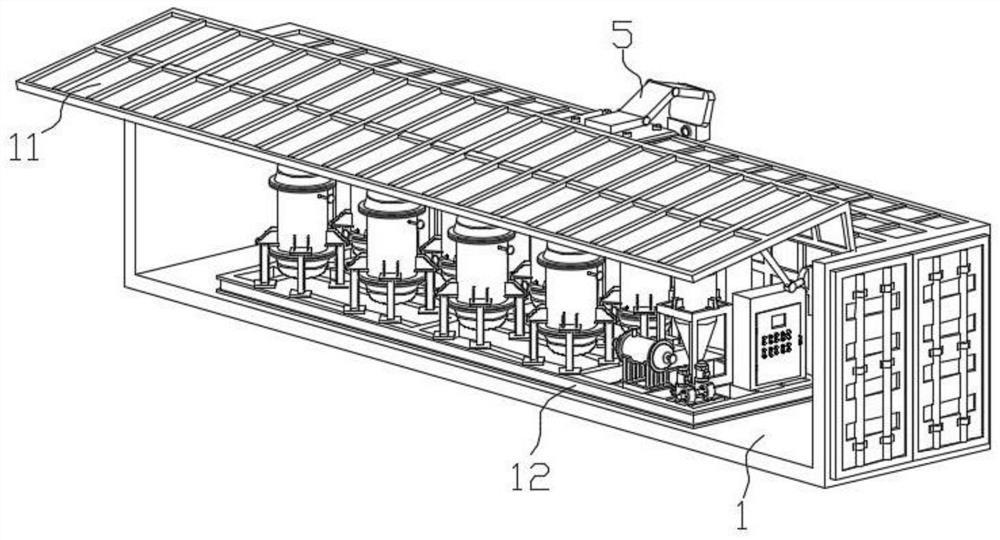

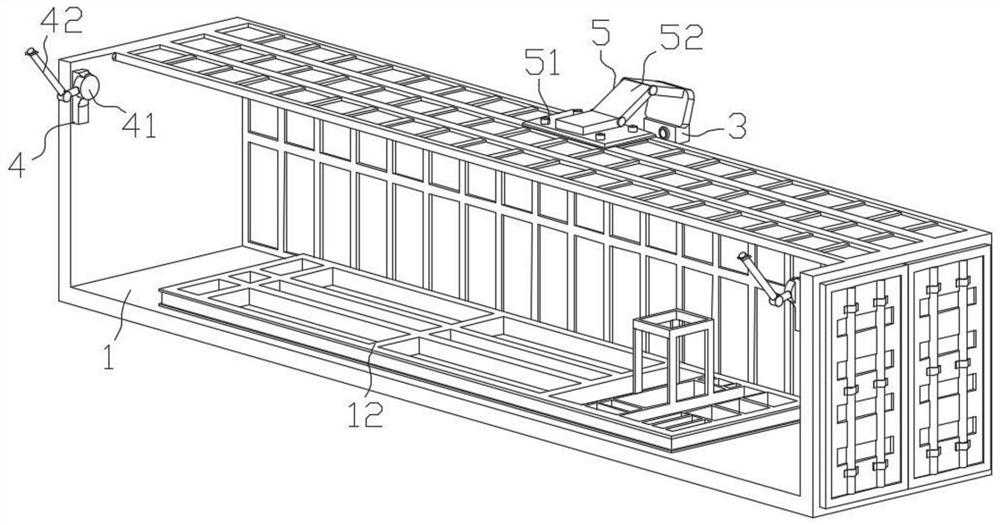

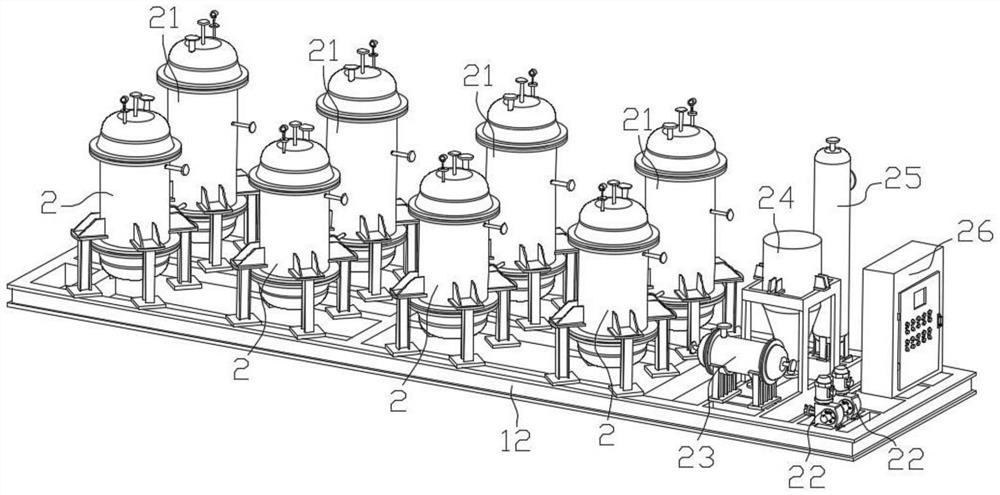

[0048] like figure 1 As shown, a mobile hydrothermal resource treatment device for high-salt and high-COD hazardous waste includes a skid body 1, one side of the skid body 1 is provided with a flying wing door 11 that can be turned up and down to open and close, and two left and right sides of the skid body 1 are provided. Each end side is provided with a set of drive mechanisms 4 which are connected with the inner side of the flying wing door 11 and control its upside-down opening and closing; the bracket 5;

[0049] Among them, such as figure 2 , 4 As shown, the driving mechanism 4 includes a rotating motor 41 and a top rod 42. The driving mechanism 4 is connected and fixed with the left and right sides of the pry body 1 through the rotating motor 41. One end of the top rod 42 is rotatably connected with the flying wing door 11, and the other end is It is connected with the output shaft of the rotating motor 41, and the rotating motor 41 can be installed in the device by...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, and the difference is that, such as Figure 5 , 6 As shown, the drive mechanism 4 also includes a positioning lock plate 6 for adjusting the support position of the ejector rod 42 and the flying wing door 11, and the bracket is a triangular bracket;

[0054] 1. Positioning lock plate 6

[0055] like Figure 9 As shown, the positioning lock plate 6 includes an annular sleeve 61, and the two inner walls of the annular sleeve 61 away from the flying wing door 11 are each provided with a fixing frame 62 for fixing two sets of main pulleys 63. A control belt 64 for controlling the extension and retraction of the magnet block 612 is sleeved,

[0056] like Figure 11 , 12 , 16, 17, 19, the main pulley 63 on the same side is slidably connected to the slot 621 provided on the fixing frame 62 through the rod body, and the slot 621 inside the rod body is provided with a spring seat 622 that contacts the rod body The end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com