Manufacturing method of online side crop recycling device

The technology of a collecting device and a manufacturing method is applied to the manufacturing field of the waste edge online collecting device, which can solve the problems of confusion on site, increase in production cost, cumbersome process, etc., and achieve the effect of saving production cost, keeping the site clean and tidy, and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

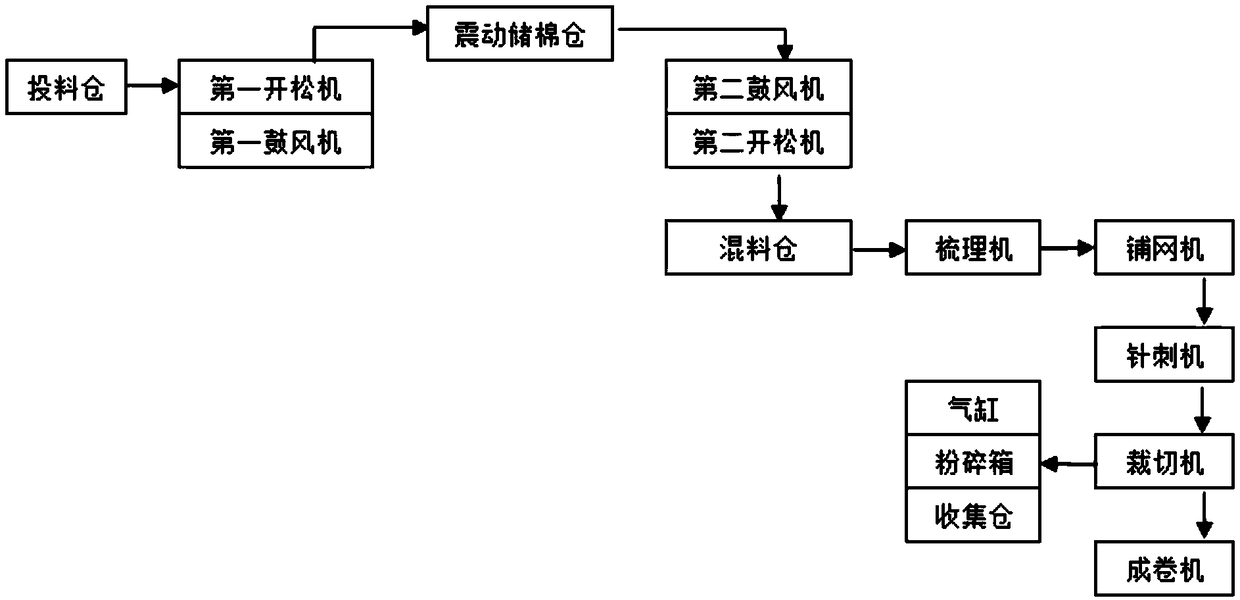

[0023] Such as figure 1 As shown, a non-woven fabric production line with a waste edge online collection device includes a feeding bin, an opening machine, a mixing bin, a carding machine, a netting machine, a needle punching machine, a cutting machine, and waste edge On-line collection device, lapping machine.

[0024] Such as figure 1 As shown, the feeding bin is located above the opener and is connected to the opener through a cotton delivery pipeline. The opener includes a rough start-up and a fine start-up, and the rough start-up includes the first opener and the second opener. The first blower connected to the opening machine, the fine start includes the second opener and the second blower connected with the second opener, a vibrating cotton storage bin is arranged between the rough starting machine and the fine starting machine, and the vibrating cotton storage bin is composed of The cotton conveying pipeline is connected with the first opener, the vibrating cotton st...

Embodiment 2

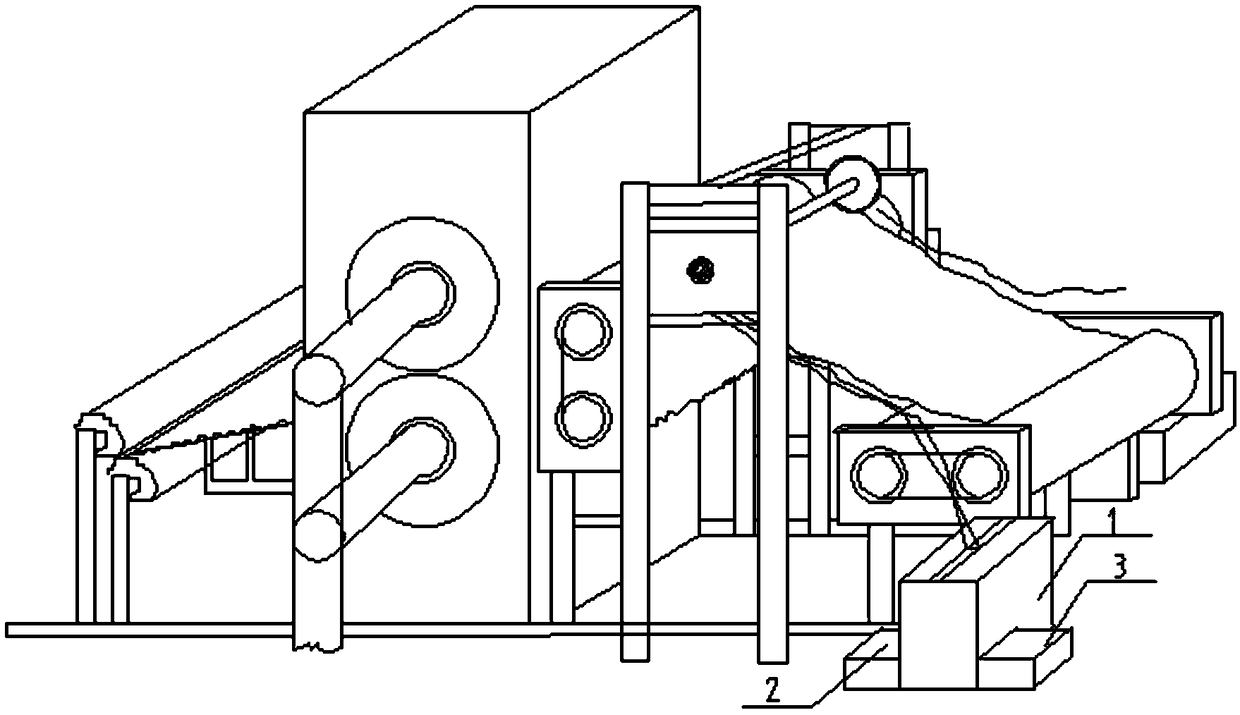

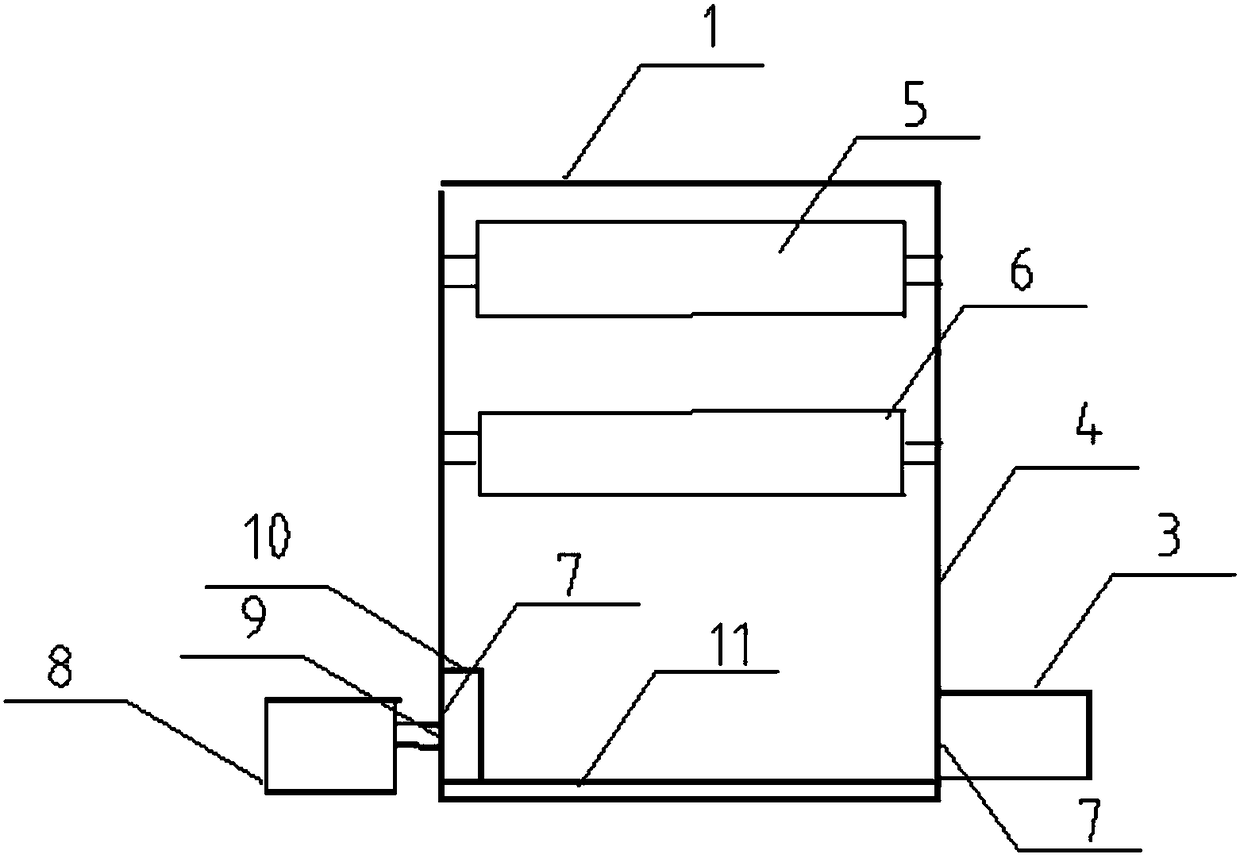

[0027] Such as Figure 2 to Figure 3 The manufacturing method of a waste edge online collection device shown is applied to a waste edge online collection device, including a crushing box 1, a push rod mechanism 2, and a collection bin 3; the crushing box 1 includes a crushing box body 4, pull rollers 5. The pulverizer 6, the pulling roller 5 is located at the top of the pulverizing box body 4, the pulling roller 5 is connected with the pulverizing box casing 4 by welding, the pulling roller 5 is located at the upper part of the pulverizer 6, and an appropriate space is left between the pulverizer 6 and the pulverizer 6. The gap, the pulverizer 6 is located in the middle part of the pulverizer 1, the pulverizer 6 is connected with the pulverizer box body 4 by welding, and two through holes 7 are arranged on the opposite side walls of the pulverizer box box body 4, and the width of the through hole 7 is the same as that of the pulverizer box body 4. The width of the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com