Transmission with at least two planet gear stages

A technology of planetary gears and planetary gear racks, which is applied to vehicle gearboxes, components with teeth, gear transmissions, etc., can solve problems such as difficult to use and insufficient installation space, and achieve the effect of reducing loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

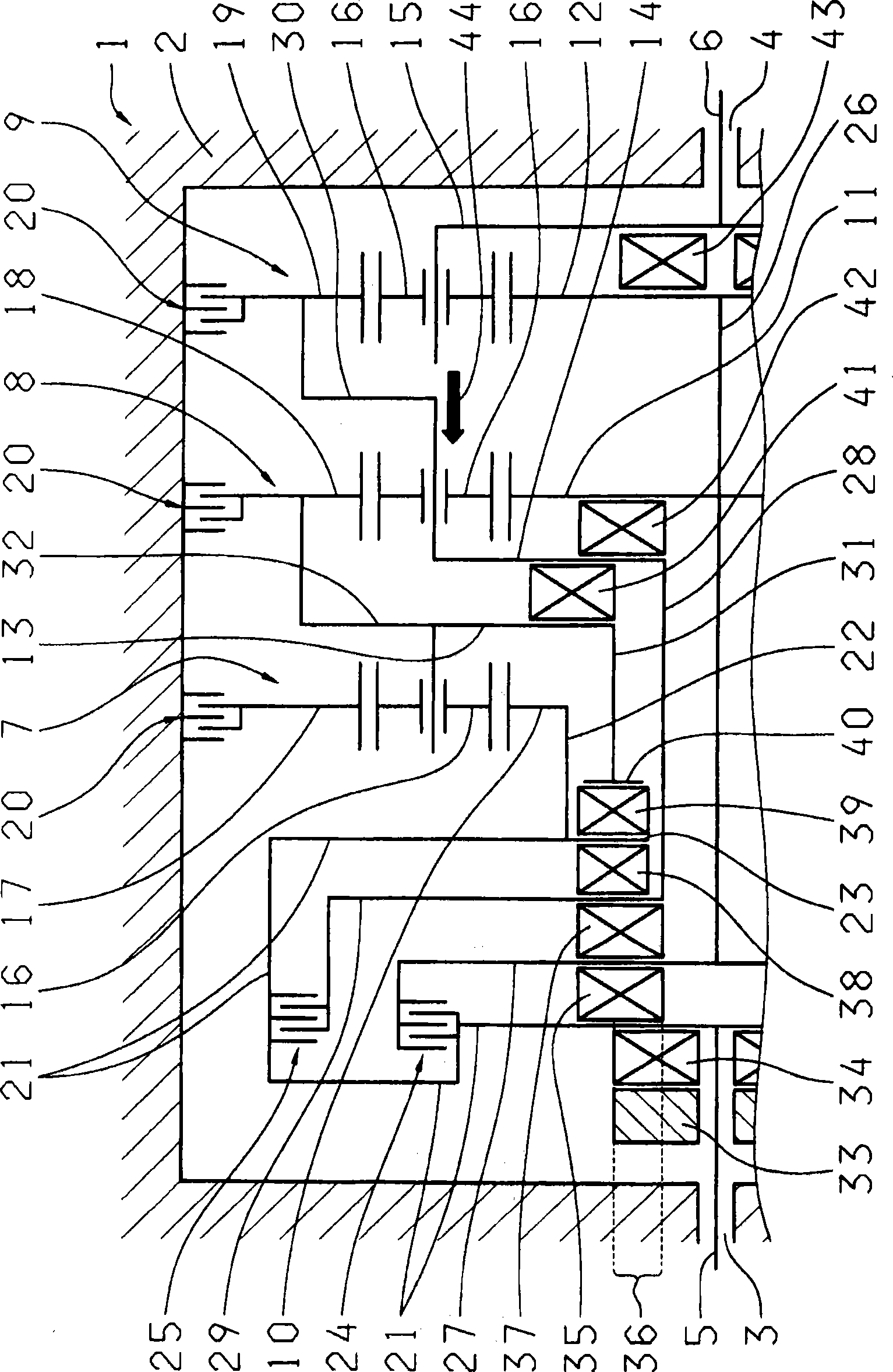

[0028] The automatic transmission 1 shown has a housing 2 which substantially encloses the transmission, and which is provided with a first opening 3 on one side and a second opening 4 on the opposite side. The gearbox 1 also includes a driving shaft 5 , which protrudes into the housing 2 through the first opening 3 ; and a driven shaft 6 protrudes from the housing 2 through the second opening 4 . The drive shaft 5 and the driven shaft 6 are arranged coaxially in sequence.

[0029] In the housing 2, a first planetary gear stage 7, a second planetary gear stage 8 and a third planetary gear stage 9 are also arranged between the driving shaft 5 and the driven shaft 6, in order to drive the driving shaft 5 The rotary motion is transmitted to the driven shaft 6. Planetary gear stages 7, 8, 9 respectively include: a sun gear 10, 11, 12; a planetary gear carrier 13, 14, 15 on which a plurality of planetary gears 16 are arranged; and an internal gear 17, 18 , 19. The planet carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com