Anticracking reinforced conductive method for assembling anode and structure thereof

A conductive structure and anti-crack technology, which is applied in the field of anti-cracking and strengthening of assembled anodes, can solve problems such as cracking of connection parts, insufficient welding contact surface, and anode shedding, so as to prevent early damage and fracture, improve electrical conductivity, and increase electrical conductivity area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

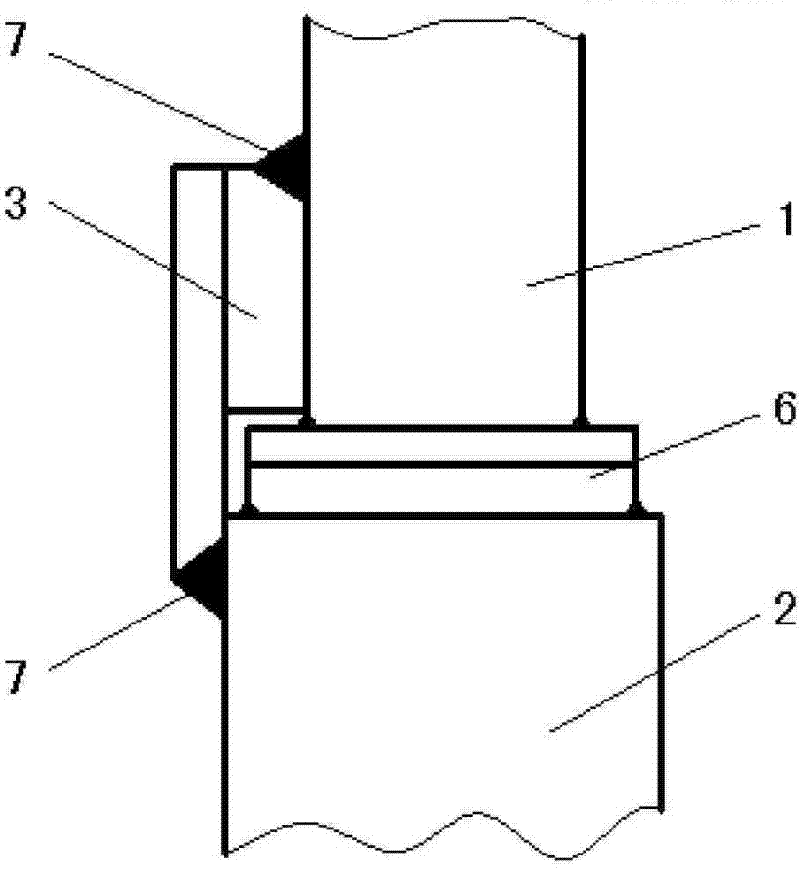

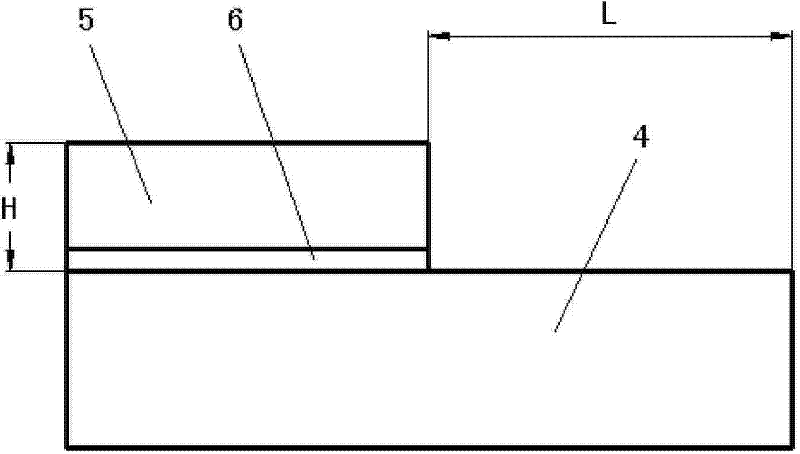

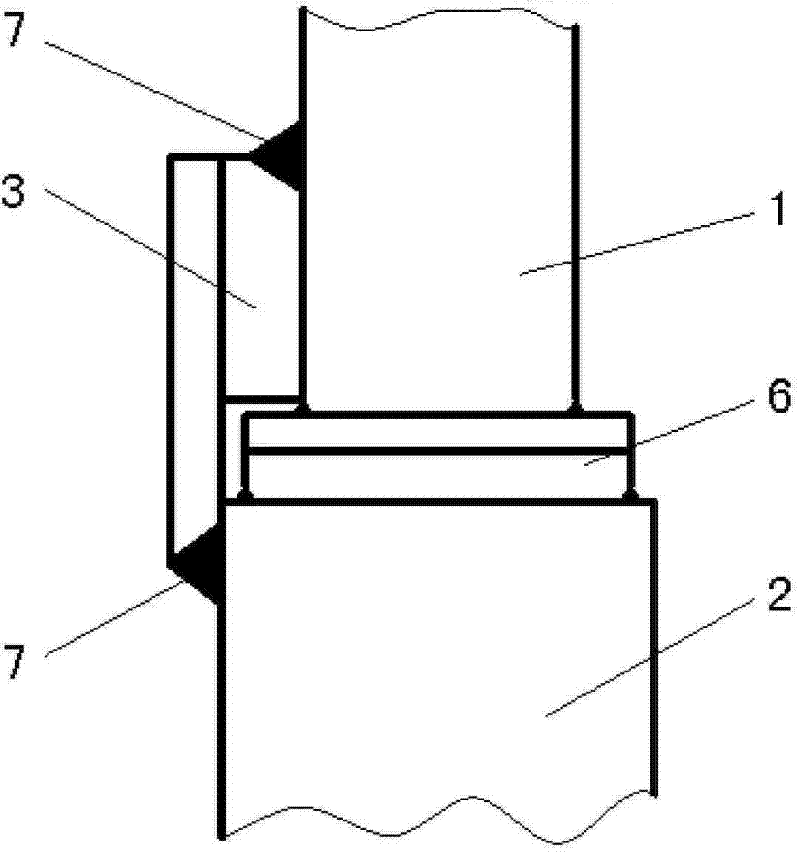

[0016] Embodiment of the present invention: when assembling the anode to prevent cracking and strengthen the conduction, a kind of aluminum-steel crack-resistant conductive sheet that can be welded and connected to the aluminum guide rod and the steel claw beam can be welded and connected to the existing connection. The integrated aluminum guide rod and the outer side of the steel claw beam; the aluminum-steel anti-crack conductive sheet is made by welding the aluminum plate and the steel plate together through the traditional aluminum-steel explosion welding sheet. The specific implementation method of assembling the anode anti-crack strengthening conductive structure is as follows: figure 1 As shown, the structure is based on the existing aluminum guide rod 1 and steel claw beam 2 connected as a whole through the aluminum-steel explosion welding piece 6, and welding is added on the outside of the connection between the aluminum guide rod 1 and the steel claw beam 2 One or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com