Solid light source, projecting system and bundling lighting fixture employing the device

A solid-state light source and solid-state light-emitting technology, which is applied to the components of lighting devices, light sources, projection devices, etc., can solve the problems of reduced light export efficiency, increased light output of light sources, and difficulty in achieving light output, so as to reduce light loss and improve The effect of light production and size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

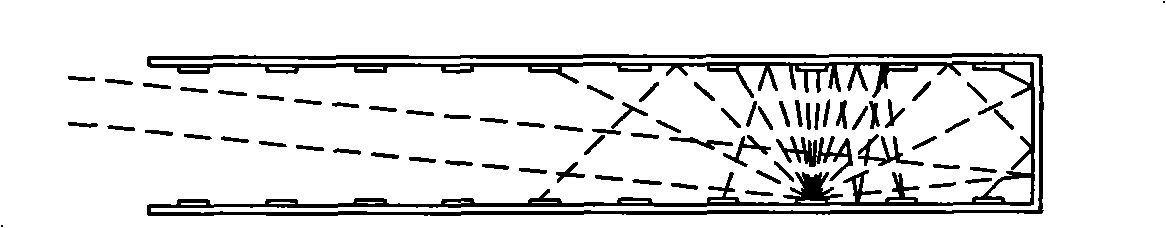

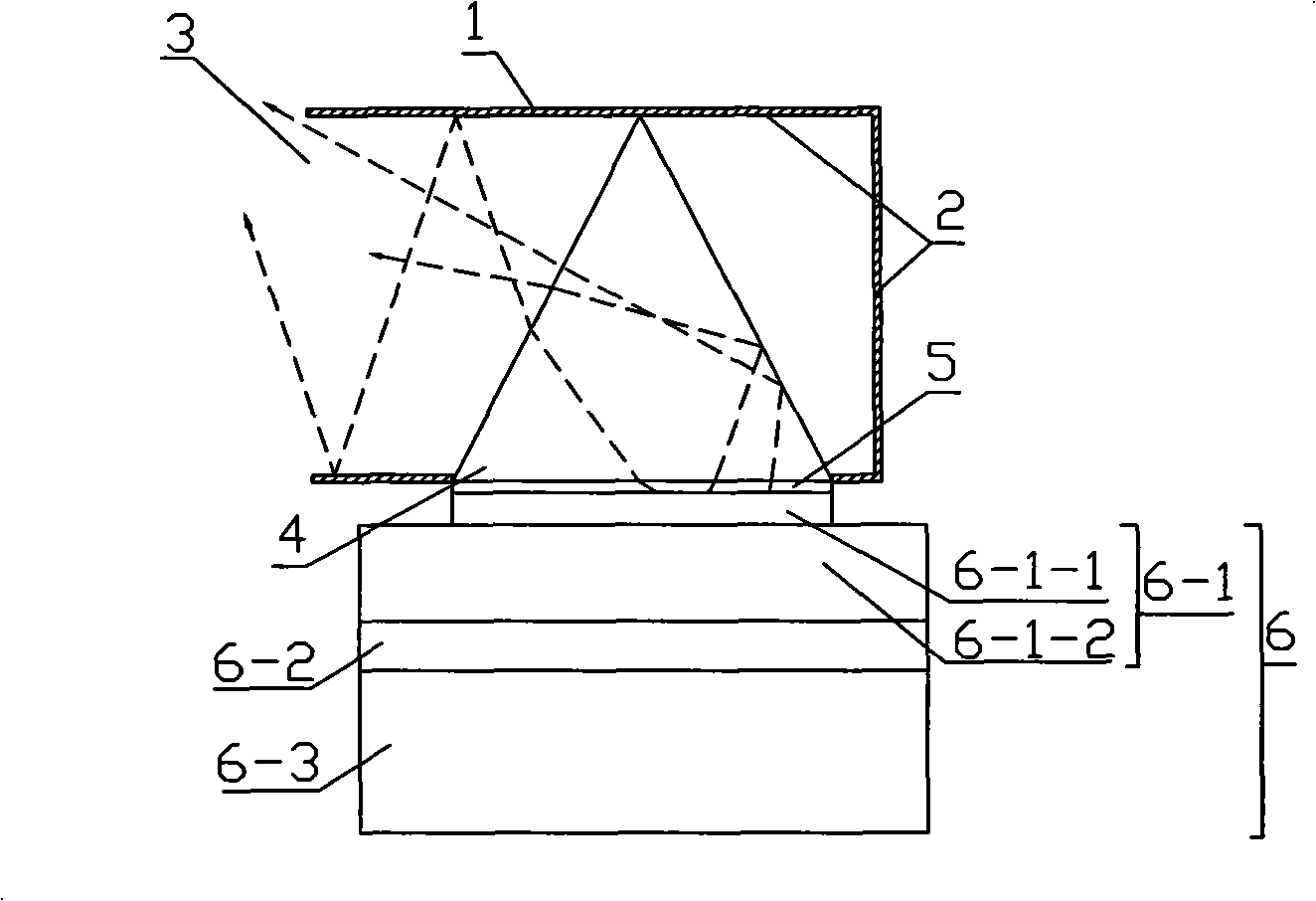

[0058] Example 1, such as image 3 As shown, a solid-state light source device includes a hollow hexahedron optical component 1, and its front wall is provided with a light outlet 3, the size of the light outlet 3 matches the projection optical system, and a light inlet is provided on the inner wall of one side of the hexahedron optical component 1. 5. A specular reflective layer 2 is provided on the inner wall surface of the optical member 1 except for the light outlet 3 and the light inlet 5, and a light guide prism 4 can be installed at the light inlet 5, as long as the sum of the bottom surface of the light guide prism 4 is equal to the light inlet 5 Matching, it is also possible to set a light guide prism array plate composed of multiple light guide prisms of different sizes in parallel without gaps. Component 6, the solid-state light-emitting component includes a light-emitting board 6-1, and the light-emitting board 6-1 is composed of a heat sink 6-1-2, a light-emitting...

Embodiment 2

[0059] Example 2, such as Figure 4a As shown, a solid-state light source device includes a hollow hexahedron optical component 1, the front wall of which is provided with a light outlet 3, the size of the light outlet 3 matches the projection optical system, and four sides of the hexahedron optical component 1 are respectively provided with four inner walls. The light entrance 5, except for the light exit 3 and the light entrance 5, the inner wall surface of the optical member 1 is provided with a specular reflection layer 2, and six light guide prisms are parallel without gaps to form a light guide prism array plate 4, which is arranged on the light entrance 5 , the light guide prism array plate 4 can also be made up of other different numbers of light guide prisms, the number of light guide prisms is related to its size, the setting of adjacent side light guide prism array plates, and the light guide prisms are symmetrical strip wedge-shaped prisms , the bottom surface of t...

Embodiment 3

[0063] Example 3, such as Figure 5a As shown, a solid-state light source device includes a hollow hexahedron optical component 1, the front wall of which is provided with a light outlet 3, the size of the light outlet 3 matches the projection optical system, and four sides of the hexahedron optical component 1 are respectively provided with four inner walls. The light entrance 5, except for the light exit 3 and the light entrance 5, the inner wall surface of the optical member 1 is provided with a specular reflection layer 2, and six light guide prisms are parallel without gaps to form a light guide prism array plate 4, which is arranged on the light entrance 5 , the light guide prism array plate 4 can also be made up of other different numbers of light guide prisms, the number of light guide prisms is related to its size, the setting of adjacent side light guide prism array plates, and the light guide prisms are symmetrical strip wedge-shaped prisms , the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com