Equipment and method for rapidly evaluating fire coal contamination risk

A pollution and risky technology, applied in the field of pulverized coal boiler combustion, can solve the problems of low efficiency, slow test process, unable to meet the actual needs of production and research, and achieve the effect of avoiding escape loss and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

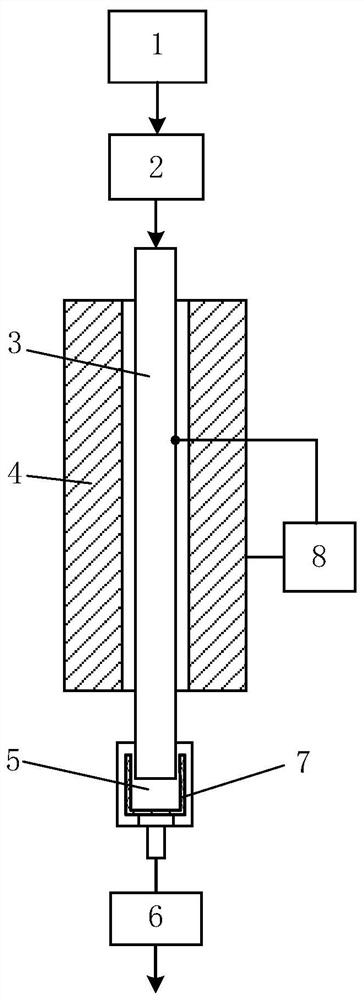

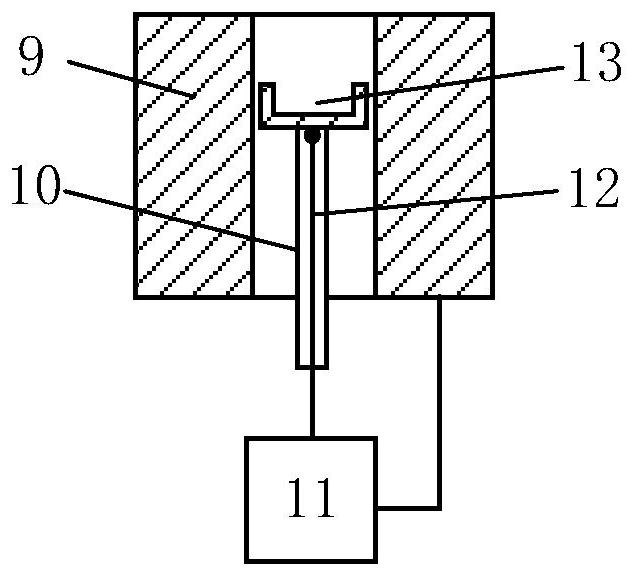

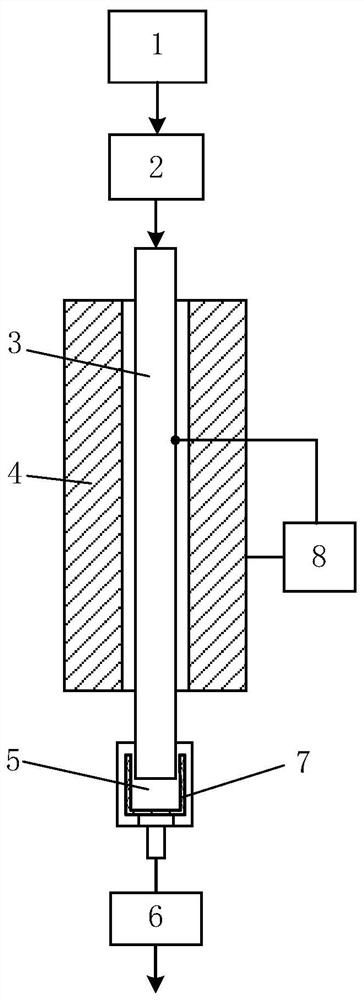

[0072] combine figure 1 and figure 2 To illustrate this embodiment, a device for quickly assessing the risk of coal-burning contamination includes a combustion ash system, a coal ash burning system, and a weighing balance; wherein the combustion ash system includes a gas distribution device 1, a pulverized coal feeding Machine 2, reaction tube 3, coal ash collector 5 and air pump 6; gas distribution device 1 is provided with a gas flow meter for regulating gas flow and component distribution ratio; reaction tube 3 is placed in heating furnace 4, and its temperature passes through the heating furnace The temperature controller 8 of 4 adjusts and controls; the coal ash collector 5 has a filter element 7 that traps coal ash particles in the flue gas; the inner diameter of the reaction tube 3 is 35-50 mm, and the length of the heating section is 350-950 mm; the coal ash is burned The system includes a high-temperature heating device 9, a crucible 13, a thermocouple 12, a crucibl...

Embodiment approach 2

[0079] combine figure 1 and figure 2 To illustrate this embodiment, the internal diameter of the reaction tube 3 is 45 mm, and the length of the heated section is 600 mm; the working temperature of the crucible 13 when burning coal ash is 1000 ° C; the resolution of the weighing balance is 0.1 mg; the reaction The material of the tube 3 is nickel-chromium alloy, and the outer wall surface is frosted and coated with a 0.1mm thick nano-silicon carbide infrared absorption coating to enhance heat exchange; the pore diameter of the filter element 7 is selected as 7 μm; the material of the crucible 13 is nickel chrome. Other implementation manners are the same as the specific implementation manner 1. This embodiment coordinates and optimizes the size of each device, which is conducive to the miniaturization of the equipment; the 0.1mm thick nano-silicon carbide infrared absorption coating can greatly enhance the temperature control response characteristics of the reaction tube, a...

Embodiment approach 3

[0081] Based on attached figure 1 and figure 2 A method for quickly assessing the risk of coal-burning contamination for equipment, implemented according to the following procedures:

[0082] Step 1: Burn the coal ash sample: use oxygen-containing gas as the transport medium, transport the pulverized coal sample into the experimental device at a uniform speed for airflow carrying combustion, and generate ash particles and flue gas; the ash particles and flue gas are pumped downstream The air pump 6 flows through the filter element 7 with a temperature of 120-200°C, and the ash particles are trapped; when the estimated amount of ash particles is greater than 3g, take out the ash sample in the filter element 7; sieve the ash sample in a dry environment , Grinding, and preparing ready-to-use ash samples whose particle sizes are all less than 90 μm;

[0083] Step 2: Ash sample burning preparation: weigh and record the empty weight of the crucible in dry state 13 m 1 , put 0.8-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com