Method for measuring elastic-strip pressure and apparatus

A method of measuring and buckle pressure technology, which is applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of low accuracy of measurement results and long measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below, and these descriptions are merely illustrative rather than limiting of the present invention.

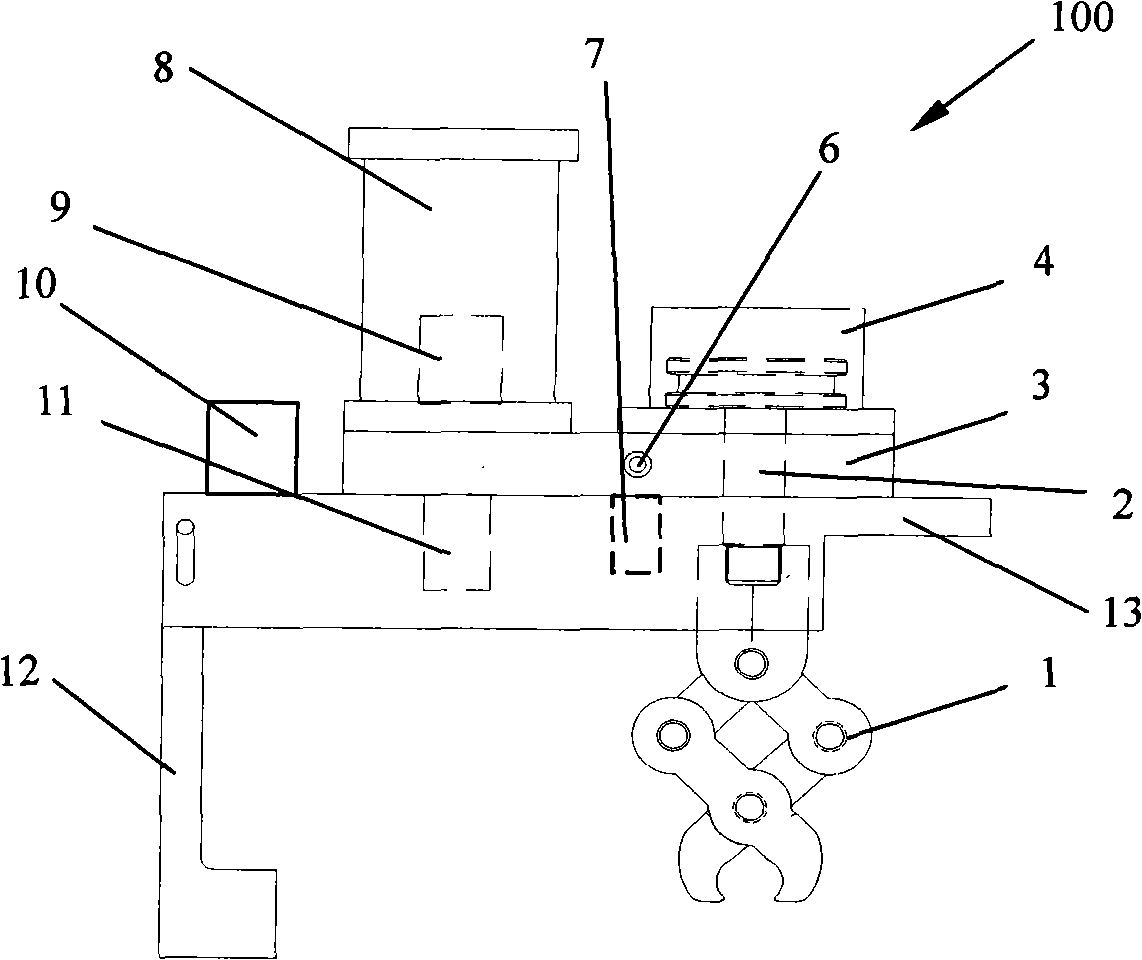

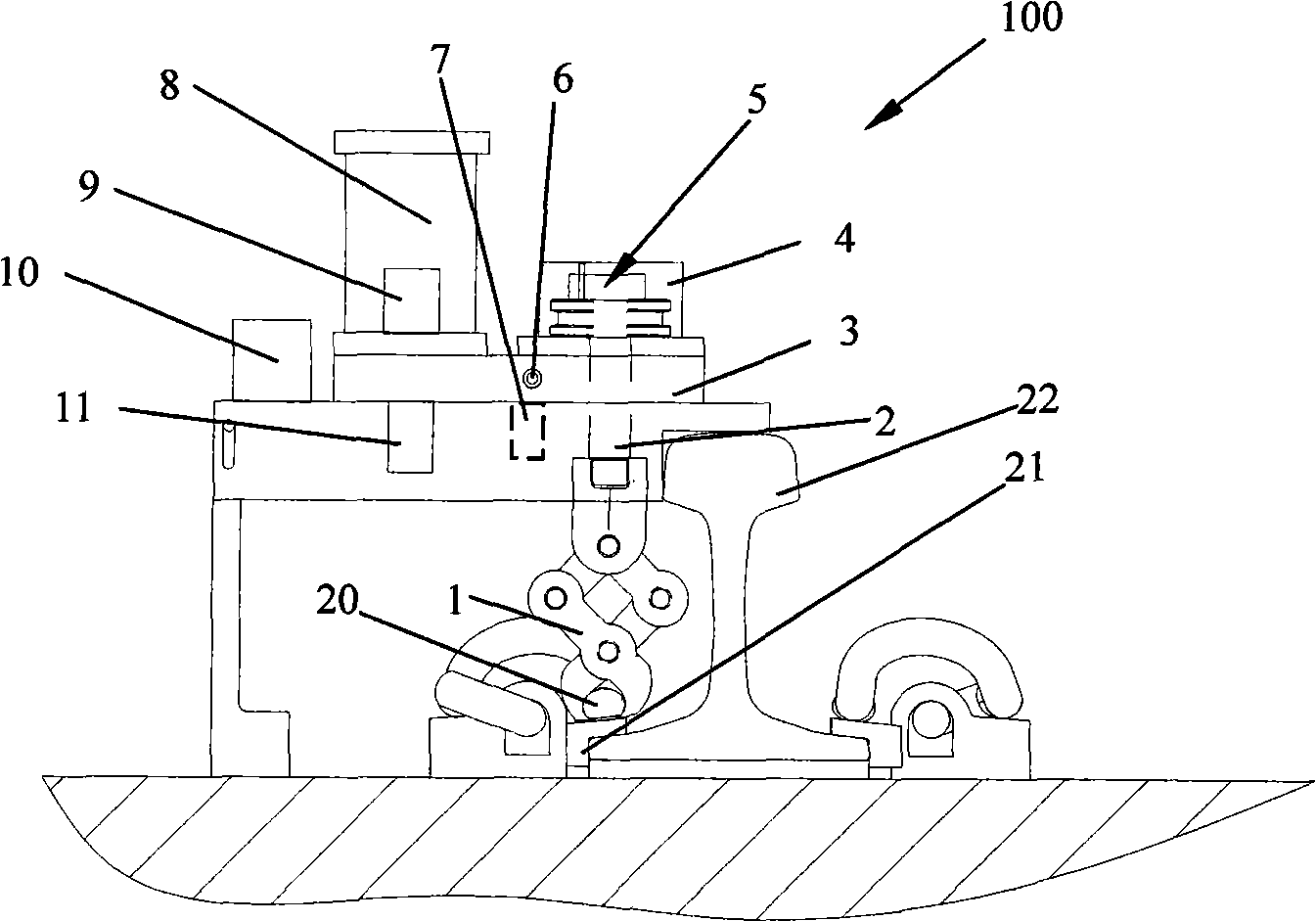

[0038] reference now figure 1 , which shows a preferred embodiment of the present invention. In this embodiment, the clip pressure measuring device is generally shown at 100 . The elastic strip buckle pressure measuring device 100 includes a clamping device for clamping the elastic strip. In this embodiment, the clamping device is a four-link clamp 1, but it is understood that other clamping devices known to those skilled in the art can also be used.

[0039] In this embodiment, the force-applying device is a hydraulic device. The hydraulic equipment includes a piston 2 , a valve block 3 , a hydraulic cylinder 4 , an oil tank 8 , a hydraulic pump 9 and a drive motor 11 . In addition, in order to release the clip 1 to restore the original position after the buckle pressure of the elastic strip is measured, an un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com