A method of manufacturing an aluminum coil terminal

A technology of terminal and production method, applied in the direction of connection, connection insulation, connection contact material, etc., can solve the problems of open circuit, affecting the service life of wire reels, corrosion of aluminum wire paint, etc., to prolong service life, overcome easy breakage, Erosion prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

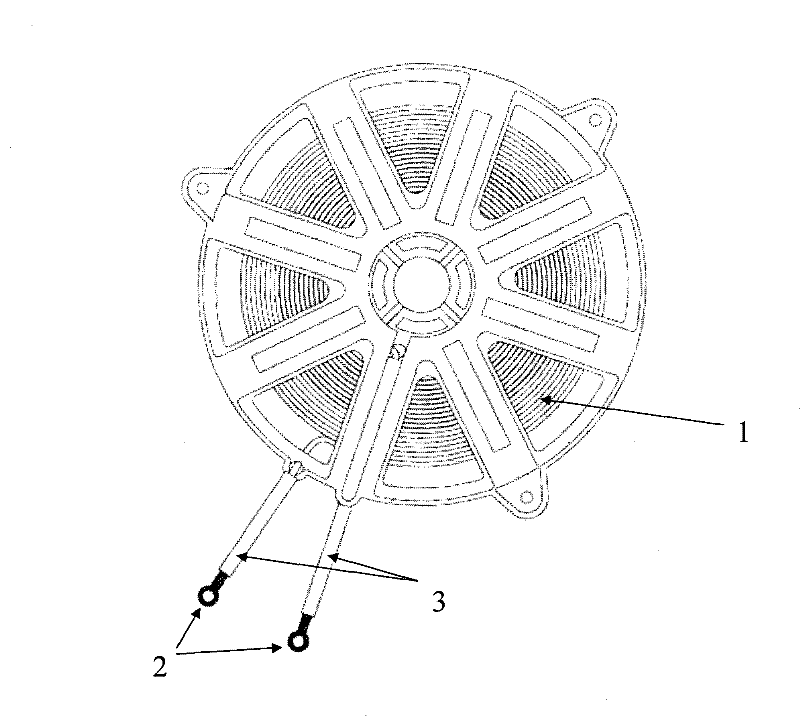

[0018] figure 1 As shown, insert the end of the lead wire 3 of the aluminum enameled wire reel 1 into the terminal 2, place it in the cold pressing equipment, and use 6 kg of pressure to flatten the terminal 2 and the end of the lead 3 inserted into the terminal 2 together. , so that the terminal 2 and the end of the lead wire 3 are fixedly connected; then place it in a hot pressing device, and use a pressure of 6 kg and a temperature of 600°C for 4 seconds to heat the same part of the cold press, and insert the lead wire inserted into the terminal 2 3. The aluminum wire at the end is softened so that the aluminum wire is closely connected with the terminal 2. The aluminum stranded wire is composed of one or more aluminum wires, and the terminal is made of metal materials.

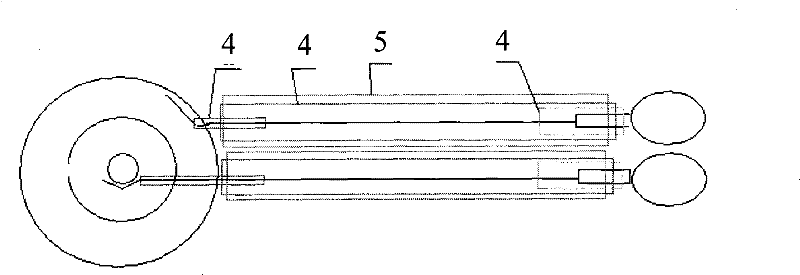

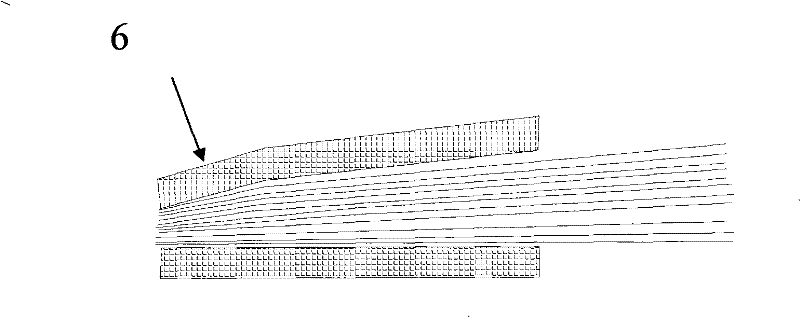

[0019] figure 2 As shown, heat-shrinkable sleeve 4 is used to wrap the aluminum enameled wire at the end of lead wire 3 of aluminum enameled wire reel 1 and the part of lead wire 3 close to aluminum ena...

Embodiment 2

[0021] Example 2: figure 1 As shown, insert the end of the lead wire 3 of the aluminum enameled wire reel 1 into the terminal 2, place it in the cold pressing equipment, and use a pressure of 4 kg to flatten the terminal 2 and the end of the lead 3 inserted into the terminal 2 together. , so that the terminal 2 and the end of the lead wire 3 are fixedly connected; then place it in a hot pressing device, and use a pressure of 4 kg and a temperature of 400°C for 6 seconds to heat the same part of the cold press, and insert the lead wire inserted into the terminal 2 The aluminum wire at the end of 3 is softened, so that the aluminum wire is closely connected with the terminal 2.

Embodiment 3

[0022] Example 3: figure 1 As shown, insert the end of the lead wire 3 of the aluminum enameled wire reel 1 into the terminal 2, place it in the cold pressing equipment, and use a pressure of 5 kg to flatten the terminal 2 and the end of the lead 3 inserted into the terminal 2 together. , so that the terminal 2 and the end of the lead wire 3 are fixedly connected; then place it in a hot pressing device, and use a pressure of 5 kg and a temperature of 500°C for 5 seconds to heat the same part of the cold press, and insert the lead wire inserted into the terminal 2 The aluminum wire at the end of 3 is softened, so that the aluminum wire is closely connected with the terminal 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com