Crusher

A pulverizer and pulverized product technology, applied in the direction of grain processing, etc., can solve the problems of damage, difficult maintenance and replacement, poor installation workability, etc., and achieve the effect of reducing cost and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

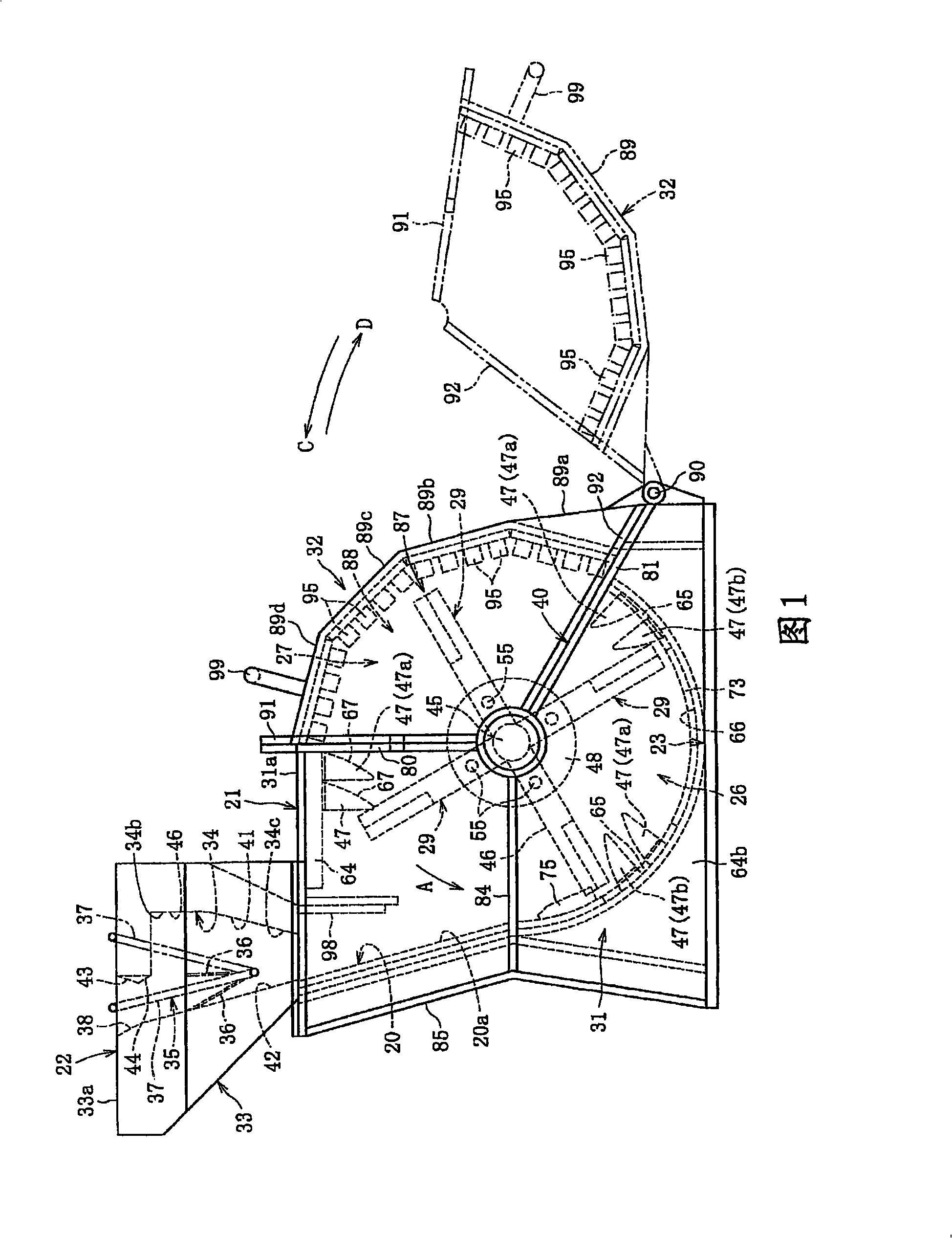

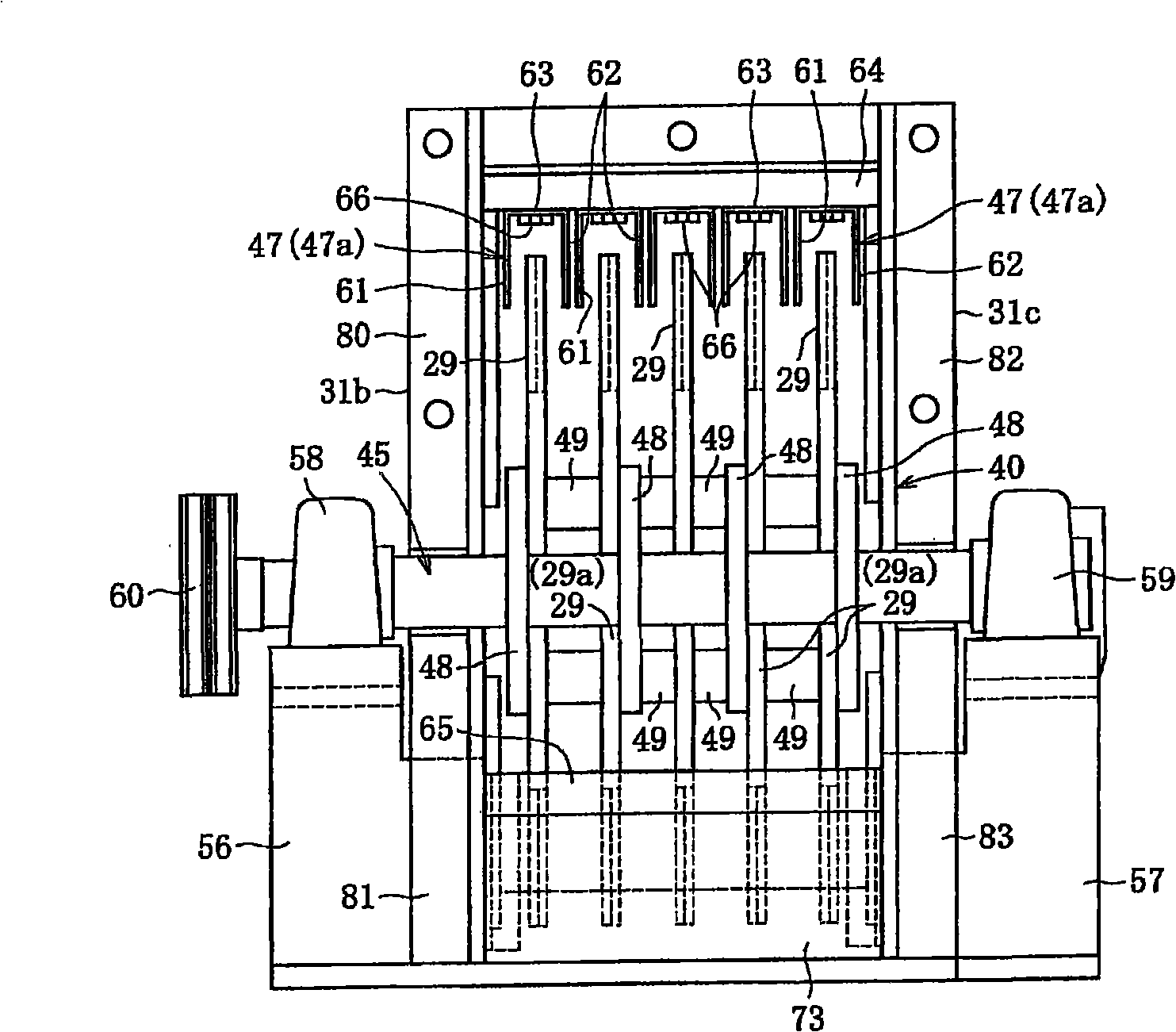

[0082] Refer to Figure 1 to Figure 16 , an embodiment of the pulverizer of the present invention will be described.

[0083] Figure 1 and figure 2 Shown in is a pulverizer using the pulverizer of the present invention. This grinder includes a casing 21 and a crushing unit 27, wherein the casing 21 has an upper inlet 22 for inputting crushed objects and a lower discharge port 23 for discharging the crushed objects, and the crushing unit 27 is arranged on the In the crushing chamber 26 in the casing 21. The crushed objects refer to various products such as paper, magnetic tape recording media such as audio cassettes, optical recording media, and substrates.

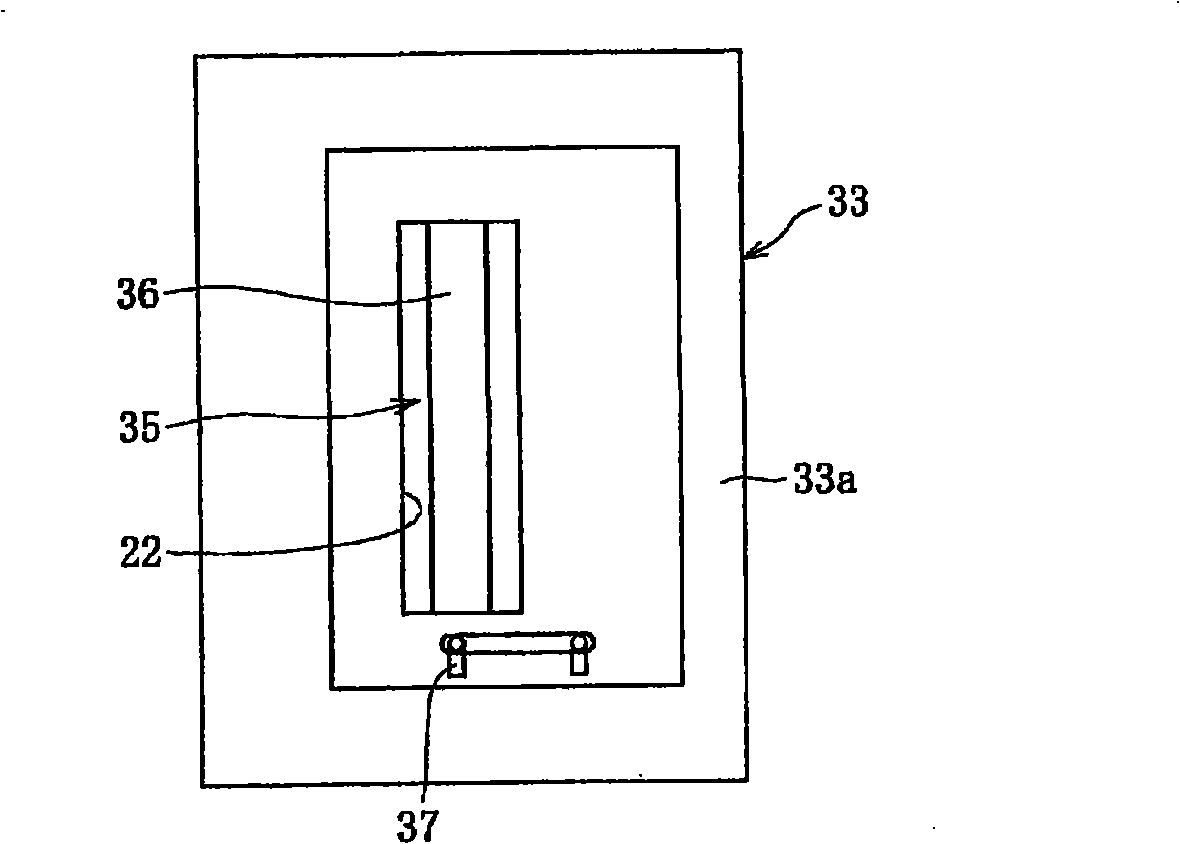

[0084] The casing 21 includes a casing main body 31 and a cover member 32 that closes an opening (side opening) 40 of the casing main body 31 . Further, a hopper 33 for throwing in crushed objects is attached to an upper wall 31 a inside the casing main body 31 , and the upper wall 33 a of the hopper 33 forms the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com