Preparation and use of PP/PE environment friendly fense composite material

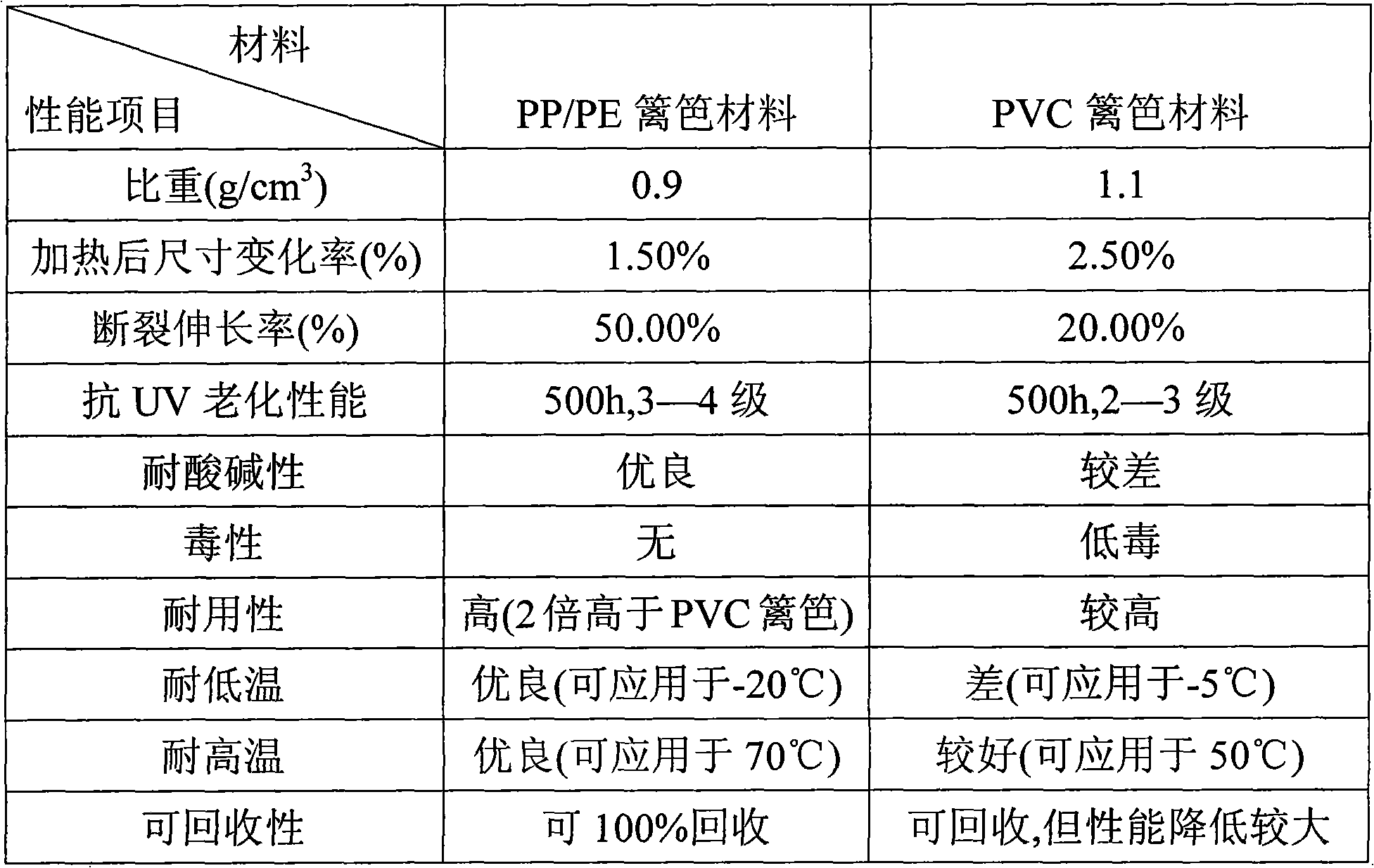

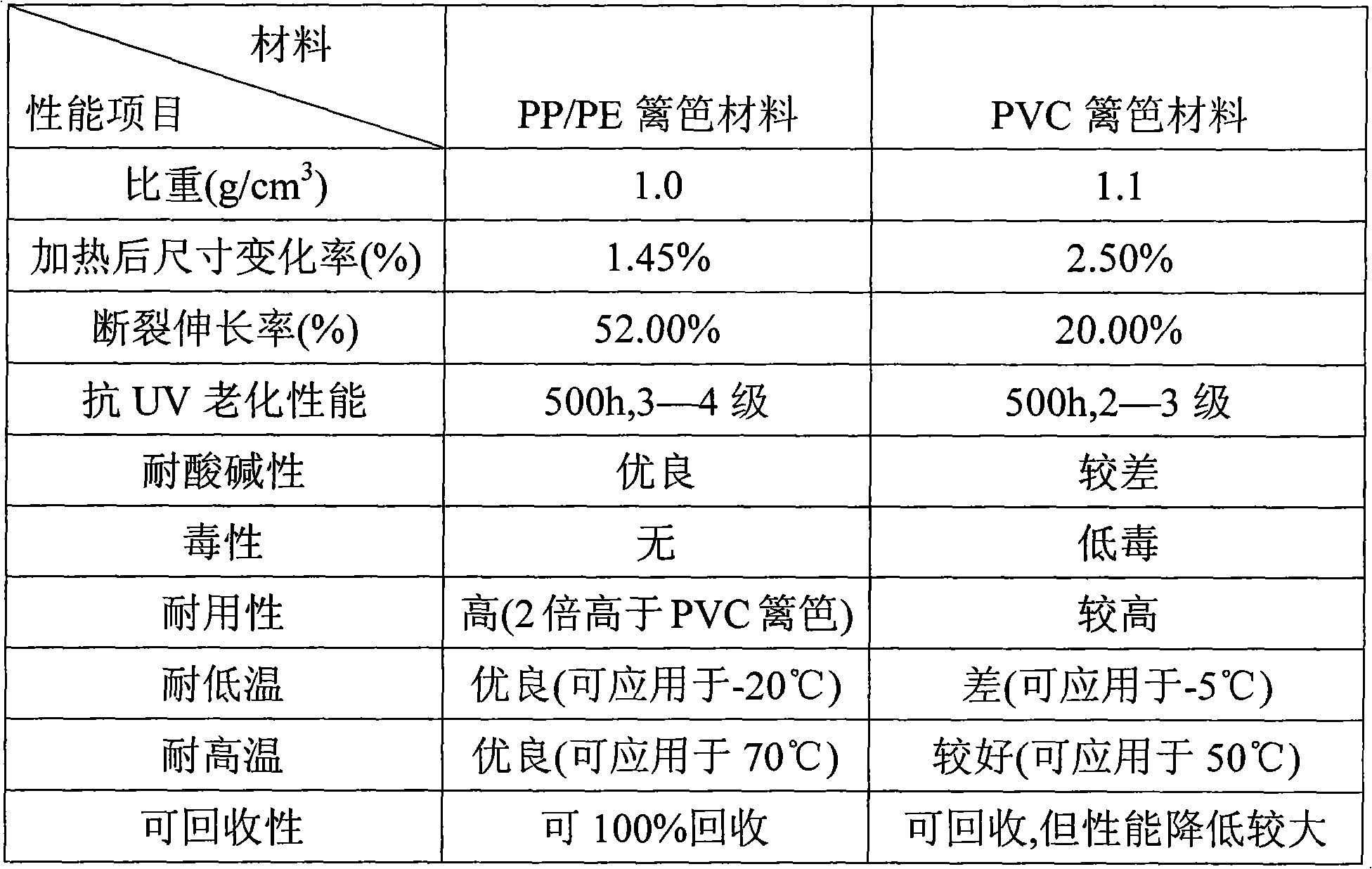

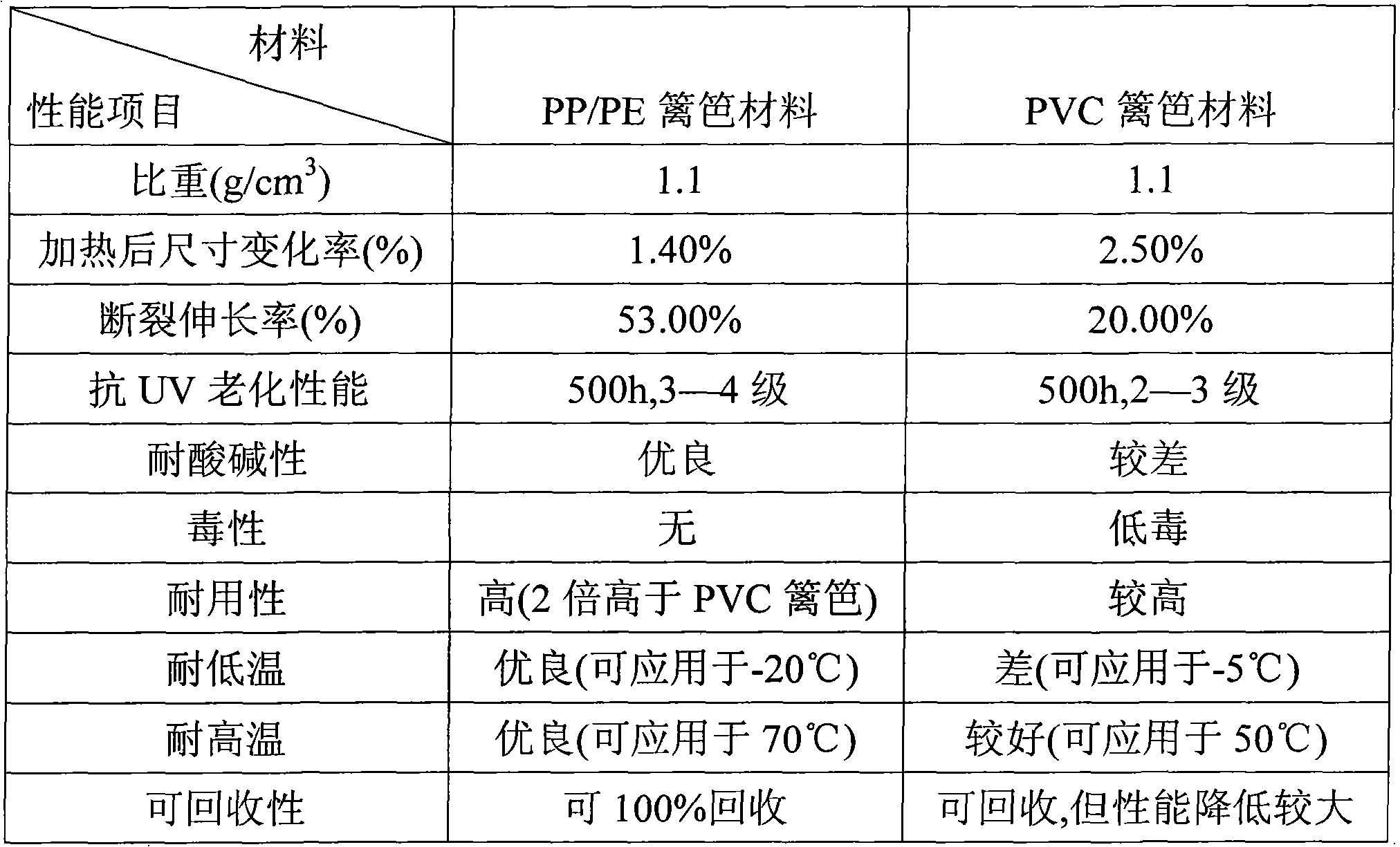

A technology of composite materials and manufacturing methods, applied in the direction of buildings, fences, building types, etc., can solve the problems of polluting the environment and high production costs, and achieve the effects of good weather resistance, improved impact strength and toughness, good rigidity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare described PP / PE environment-friendly fence composite material according to the following steps:

[0025] Step 1: In parts by weight, add 50 parts of 1000-mesh talc powder into the mixing pot and mix at high speed to 110°C to remove the moisture, then add 1.5 parts of titanate coupling agent (NDZ105) and mix at high speed for 4 minutes , then add 50 parts of PP resin, 0.5 parts of antioxidant (1010), 0.5 parts of ultraviolet absorber (UV-531), mix for 3 minutes, put it into the cold mixing pot and mix it to 45 ° C for feeding;

[0026] Step 2: Use the co-rotating parallel twin-screw extruder to prepare the PP reinforced filling masterbatch through the steps of drawing, water cooling, pelletizing and drying with the co-rotating parallel twin-screw extruder. The operation process is as follows:

[0027] Host speed: 300r / min; Feeding speed: 75r / min;

[0028] Set the temperature of each section of the screw: barrel 1: 170°C; barrel 2: 175°C; barrel 3: 180°C; barrel...

Embodiment 2

[0036] Prepare described PP / PE environment-friendly fence composite material according to the following steps:

[0037] Step 1: In parts by weight, add 70 parts of 1000 mesh talc powder into the mixing pot and mix at high speed to 115°C to remove the moisture, then add 2 parts of titanate coupling agent (NDZ105) and mix at high speed for 6 minutes , then add 70 parts of PP resin, 0.8 parts of antioxidant (1010), 0.8 parts of ultraviolet absorber (UV-531), mix for 4 minutes and put it into the cold mixing pot to cool and mix to 45 °C for feeding;

[0038] Step 2: Use the co-rotating parallel twin-screw extruder to prepare the PP reinforced filling masterbatch through the steps of drawing, water cooling, pelletizing and drying with the co-rotating parallel twin-screw extruder. The operation process is as follows:

[0039] Host speed: 350r / min; Feeding speed: 90r / min;

[0040] Set the temperature of each section of the screw: barrel 1: 176°C; barrel 2: 179°C; barrel 3: 186°C; b...

Embodiment 3

[0048] Prepare described PP / PE environment-friendly fence composite material according to the following steps:

[0049] Step 1: In parts by weight, add 100 parts of 1000 mesh talc powder into the mixing pot and mix at high speed to 120°C to remove the moisture, then add 3 parts of titanate coupling agent (NDZ105) and mix at high speed for 8 minutes , then add 100 parts of PP resin, 1.0 part of antioxidant (1010), 1.0 part of ultraviolet absorber (UV-531), mix for 5 minutes, put it into the cold mixing pot and mix it until it is 45 °C for feeding;

[0050] Step 2: Use the co-rotating parallel twin-screw extruder to prepare the PP reinforced filling masterbatch through the steps of drawing, water cooling, pelletizing and drying with the co-rotating parallel twin-screw extruder. The operation process is as follows:

[0051] Host speed: 400r / min; Feeding speed: 100r / min;

[0052] Set the temperature of each section of the screw: barrel 1: 179°C; barrel 2: 180°C; barrel 3: 189°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com