Variable pitch control method for large-sized wind-driven generator group

A technology for a wind turbine generator set and a control method, which is applied to the control of wind turbines, wind turbines, and wind energy power generation, etc., can solve the problems of difficulty in improving control accuracy, adverse mechanical component life, and reduced effects in complex situations, and achieves improved action effectiveness. , low cost, the effect of increasing the total annual power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

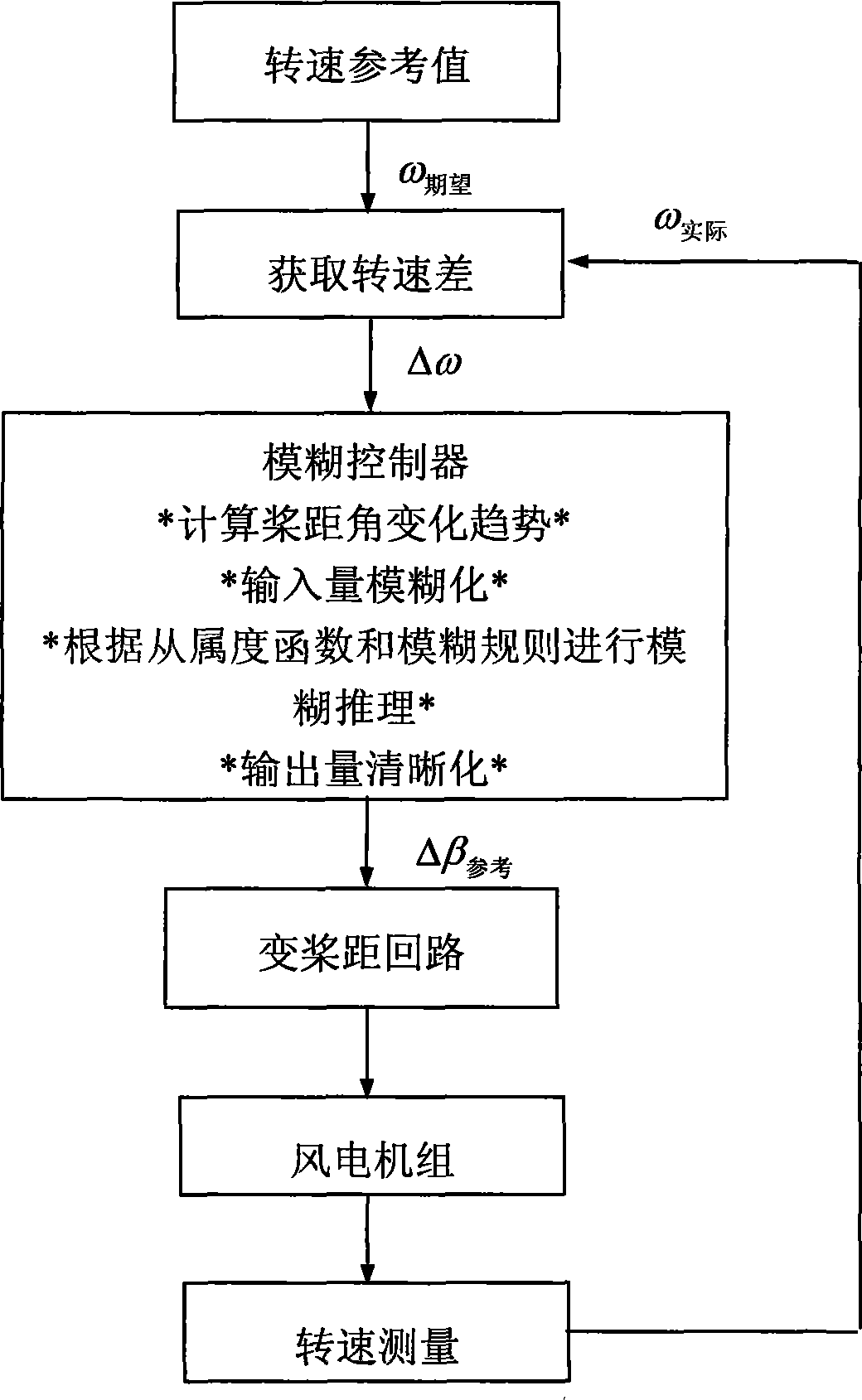

[0025] As shown in the figure, the pitch control method of a large-scale wind power generating set according to the present invention includes the following steps,

[0026] 1. According to the "wind speed-power-speed" model preset by the manufacturer, the expected value of the current main bearing speed (ω 期望 );

[0027] 2. Obtain the actual value of the current main bearing speed (ω 实际 );

[0028] 3. The current expected spindle speed (ω 期望 ) minus the actual speed (ω 实际 ) to obtain the rotational speed error (Δω); 4. The fuzzy controller comprehensively synthesizes the rotational speed difference (Δω) and its variation trend, and calculates the corresponding pitch angle reference value (β 参考 );

[0029] The specific method is that the fuzzy controller first uses the Mamdani method or the Takagi-Sugeno method, and uses the single-point fuzzy set method or the geometric shape fuzzy set method to fuzzify the speed difference (Δω) and its changing trend, and then according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com