Mounting frame and support of photovoltaic components and mounting method thereof

A photovoltaic module and support frame technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of low annual power generation, low total solar radiation, and high installation labor intensity, and reduce labor intensity. ,Easy to disassemble, improve the effect of annual power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

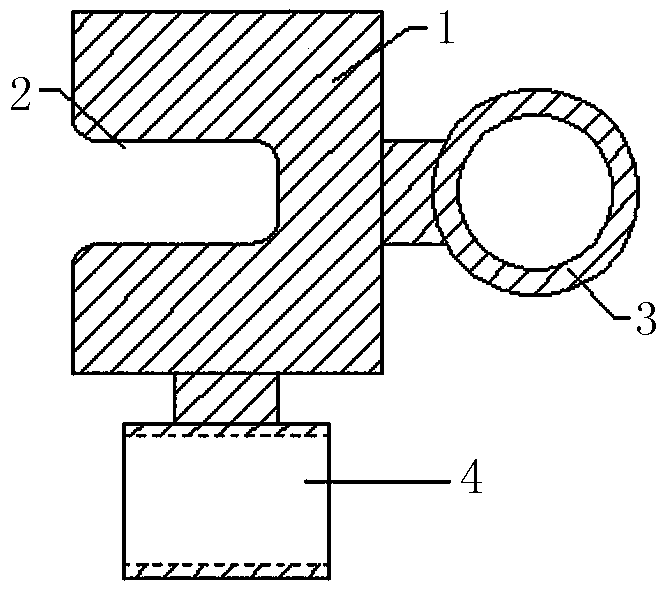

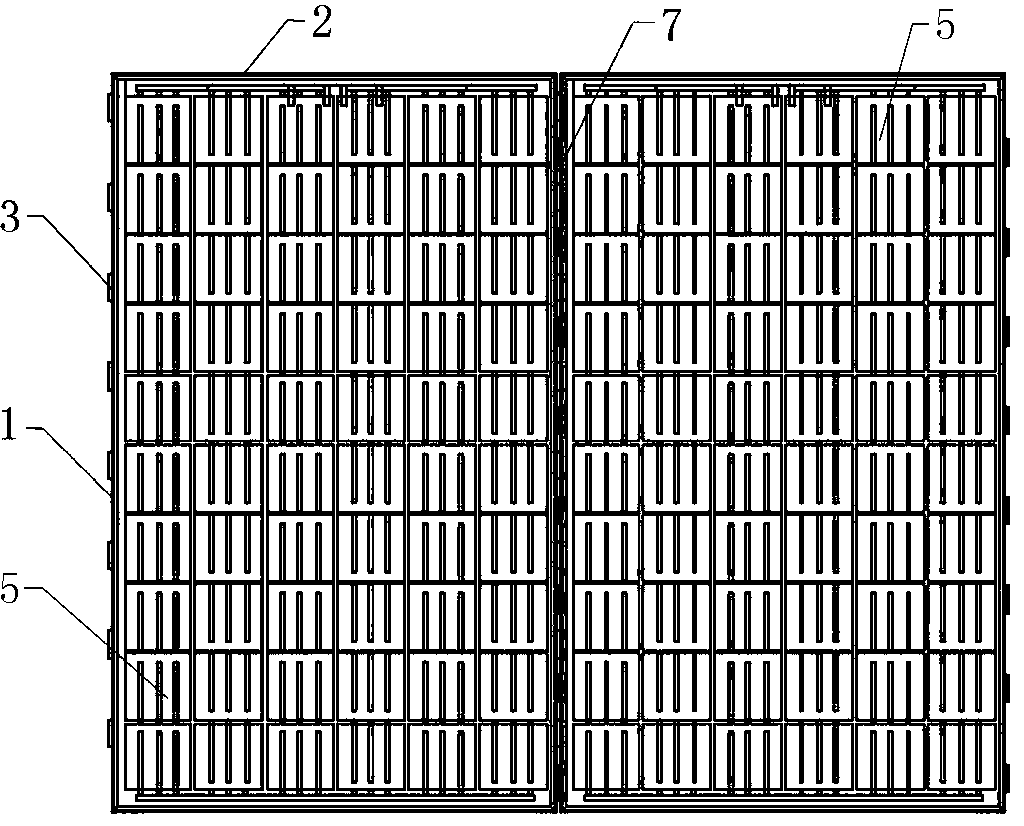

[0024] Embodiment 1: as attached figure 1 , figure 2 , image 3 As shown, a photovoltaic module installation frame, the installation frame includes a long frame body 1, a short frame body 10, a beam 6, and a slanted beam 7, wherein the side of the long frame body 1 is provided with a card slot I2 for installing a photovoltaic module 5, The other side is provided with some inclined beam connecting cylinders 3 matched with the inclined beams 7, and two crossbeam connecting cylinders 4 matched with the crossbeams 6 are respectively arranged at both ends of the bottom of the long frame main body 1; There is a card slot II11 for installing the photovoltaic module 5; the crossbeam 6 and the inclined beam 7 are respectively provided with a nut 12 at one end and a thread 13 at the other end, wherein the crossbeam 6 matches the length of the main body 1 of the long frame, and the inclined beam 7 and the short The bezel body 10 is matched in length. The beam 6 is connected with the ...

Embodiment 2

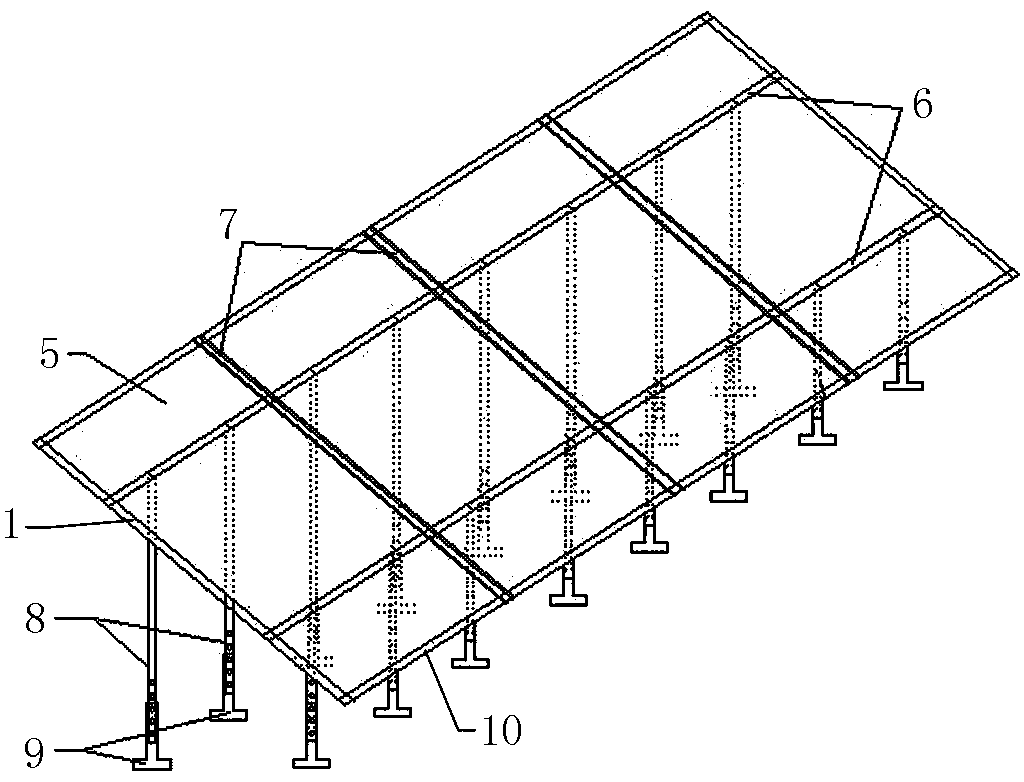

[0025] Embodiment 2: as attached Figure 4 , Figure 5 As shown, a photovoltaic module installation support frame, the support frame includes a support rod 8 and a support foot 9, the upper end of the support rod 8 is provided with a connecting cylinder 14, the inner diameter of the connecting cylinder 14 matches the outer diameter of the beam 6, and is used to match the The beam 6 is connected; the supporting foot 9 includes a connecting rod 15 and a chassis 16, the upper part of the connecting rod 15 is hollow, the inner diameter of the hollow part matches the outer diameter of the supporting rod 8, and the lower part of the supporting rod 8 and the upper part of the supporting foot 9 Threaded holes 17 with the same diameter are respectively provided, among which five are provided at the lower part of the supporting rod 8, and three are provided at the upper part of the connecting rod 15, and the supporting rod 8 and the connecting rod 15 are fixedly connected by bolts. Two...

Embodiment 3

[0026] Embodiment 3: as attached Figure 6 , Figure 7 As shown, an installation method for installing photovoltaic modules using the above-mentioned installation frame and installation support frame is as follows:

[0027] Step 1: Fix the front and rear rows of support feet 9 on the installation site through the installation holes 18 with bolts;

[0028] Step 2: Adjust the required installation angle of the photovoltaic module as needed, that is, by adjusting the connection positions of the front and rear rows of support rods 8 and the threaded holes 17 of the connecting rod 15, and then use bolts to fix the front and rear rows of support feet 9 and the support rods 8 connect;

[0029] The third step: use two beams 6, from left to right or from right to left, connect the front and back rows of support rods 8 in turn through the connecting cylinder 14 at the upper end of the support rods 8;

[0030] Step 4: Insert each group of photovoltaic modules 5 into the card slots I2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com