Photovoltaic system platform

A photovoltaic system and bench technology, which is applied in photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of inconvenient crossing of gaps, high labor intensity, poor effect, etc. The effect of increasing net income and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

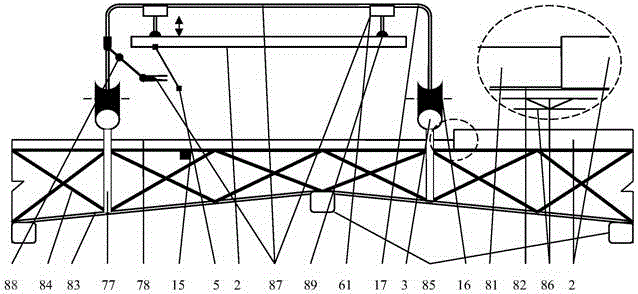

[0044] Example 1, manufacturing a photovoltaic power generation system with tracks, including a stand 1, a photovoltaic module 2, a power transmission and transformation device, a computer control system, a set of two parallel steel pipe tracks 3, and an electric device running on the track 3—— A general-purpose photovoltaic robot and an upper rail platform 4; the track 3 is connected to the platform 1 through an insulating supporting member 6; the arrangement direction of the track 3 is parallel to the arrangement direction of the platform 1 . The platform 1 includes a column 7, a cross bar, a diagonal brace, an accessory and a foundation pile 8; The photovoltaic assembly 2 is installed on the stand 1; the photovoltaic assembly 2 is electrically connected to the power transmission and transformation device through the output wire terminal 30 and the electrical socket 15. The insulating supporting member 6 is made of steel, and contains an insulating material tile between it a...

Embodiment 2

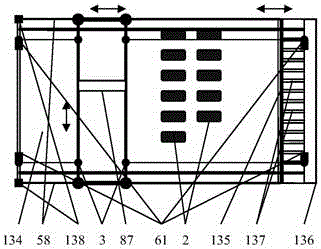

[0063] In Example 2, the photovoltaic power generation system includes a stand 1, a photovoltaic module 2 drawn by a dotted line, a power transmission and transformation device, and a computer control system. Pad blocks 57 are arranged on both sides of the photovoltaic power generation system, and a group of two parallel steel pipe rails 3 are installed and connected on the pad blocks 57 through the insulating supporting member 6 . At least one track 3 is electrically insulated and installed with the outside; a group of two tracks 3 is electrically connected to two electrodes of the power supply; the cleaning module 18 obtains electric energy through the track 3 . The two groups of electric wheel sets 16 that cooperate with the track 3 to roll and connect are connected as a whole by a spanning frame 17. Several winches 61 are evenly distributed above the frame 17, and the hoists 61 hang down the cables 58 to implicate the cleaning module 18 below. For the content of the cleani...

Embodiment 3

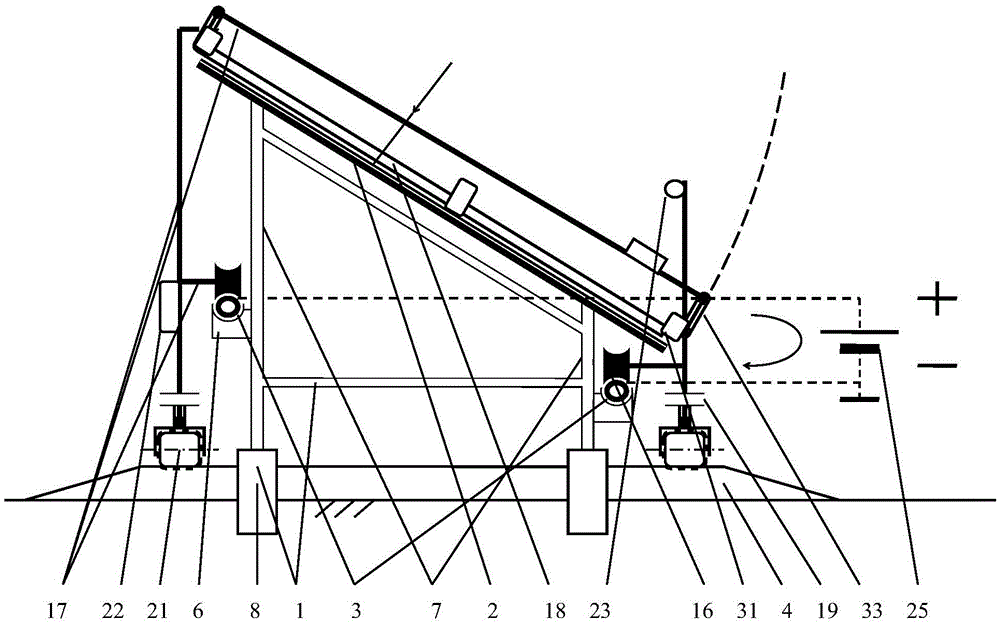

[0075] In Embodiment 3, a magnetic roller brush is manufactured—shown by a dotted circle in the figure, which is used as a current collector, including a brush 24 and at least one magnetic roller 70 . The magnetic roller 70 is disposed on the front side and / or the rear side of the brush 24 . The magnetic roller brush is connected to the steel rail-shaped power transmission bus 72 by sliding / rolling and is electrically connected. The rail-shaped power transmission bus 72 is a horizontal bar of a photovoltaic system stand that is insulated and connected to the column 7 through the insulating material 68, and is made of paramagnetic material. The rail-shaped power bus 72 can be electrically connected to the poles of a power source. The magnetic attraction roller 70 is arranged on the front side and / or the rear side of the brush 24, which helps to prevent and slow down the jumping of the brush 24 in motion and maintain a good working condition. A dust cover can also be provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com