Continuous flue gas monitoring electronic refrigerator

An electronic refrigeration and flue gas technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of slow heat exchange speed, high energy consumption, and loud noise, and achieve high temperature control accuracy and low energy consumption , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

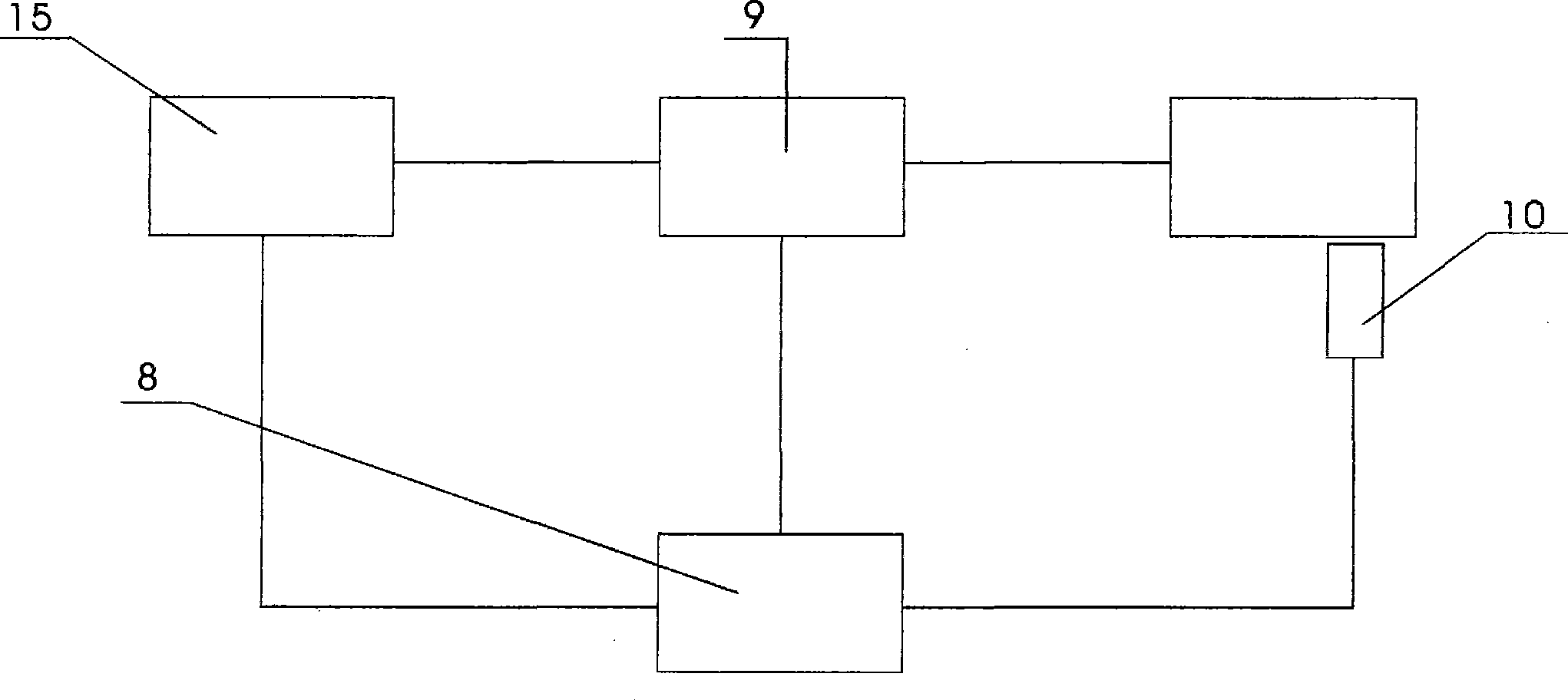

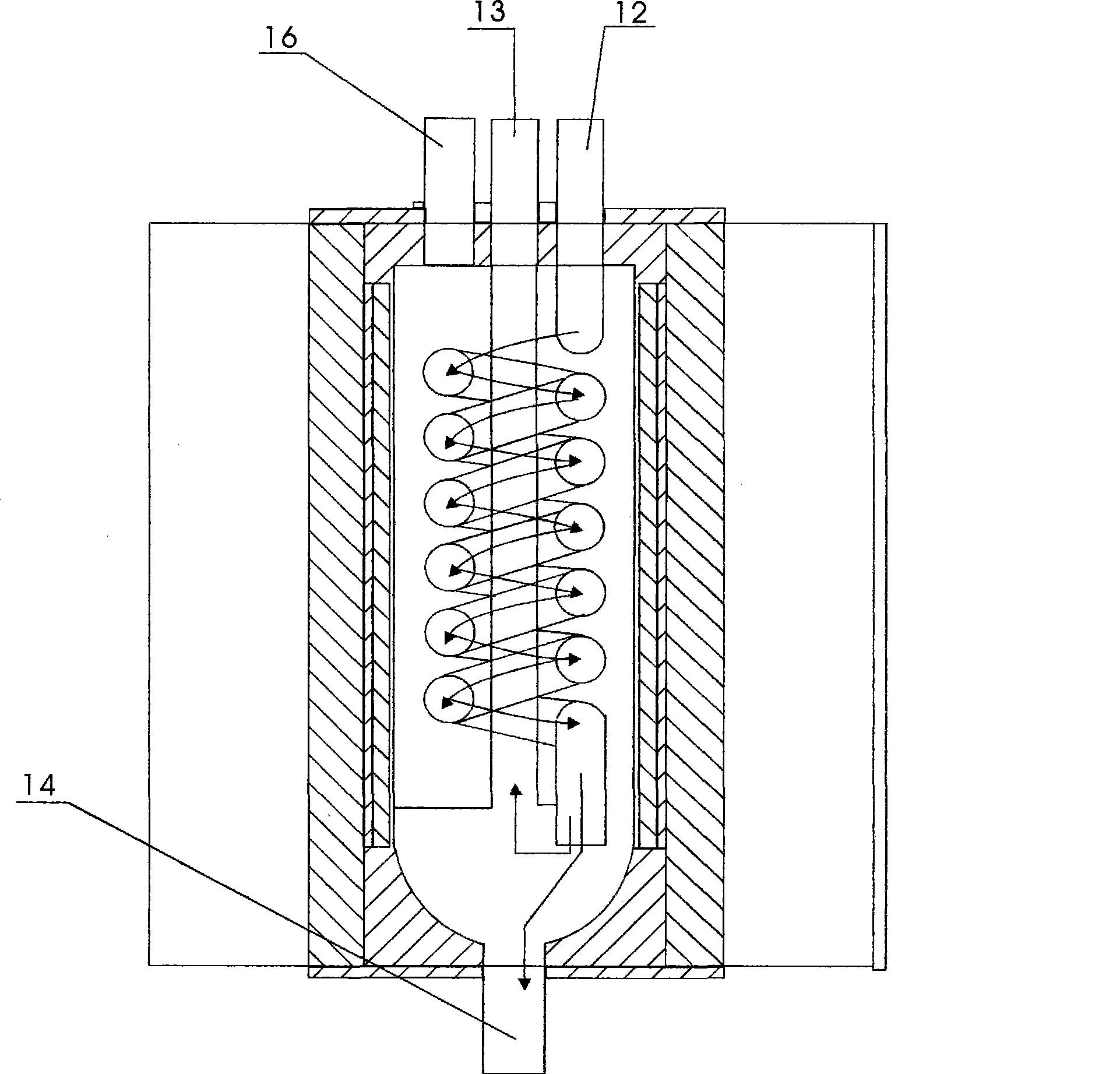

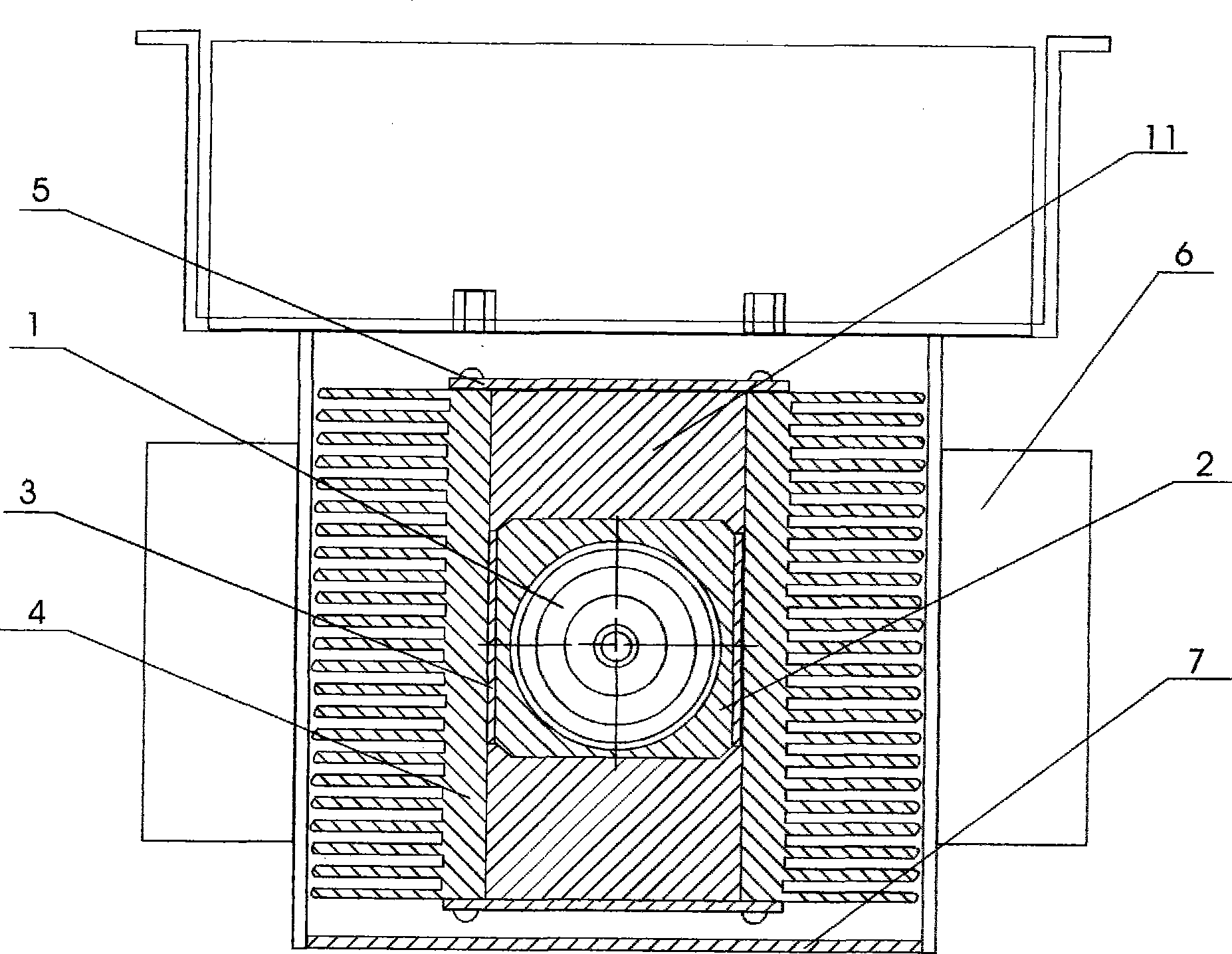

[0016] As shown in the figure, the present invention mainly comprises acid and alkali resistant borosilicate glass tube 1, aluminum aluminum core 2, semiconductor refrigeration sheet 3, cooling fin 4, closing plate 5, cooling fan 6, box body 7, PID (ratio Integral differential control) temperature controller 8, solid state relay 9, platinum resistance temperature sensor 10, characterized in that: the acid and alkali resistant borosilicate glass tube 1 is installed in the aluminum core 2, and the heat-conducting silicone glue The two parts are in complete contact, and the two semiconductor cooling chips 3 are tightly attached to the outer surface of the aluminum aluminum core 2 with heat-conducting silicone grease. The surface is fully contacted with heat-conducting silicone glue, the studs firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com