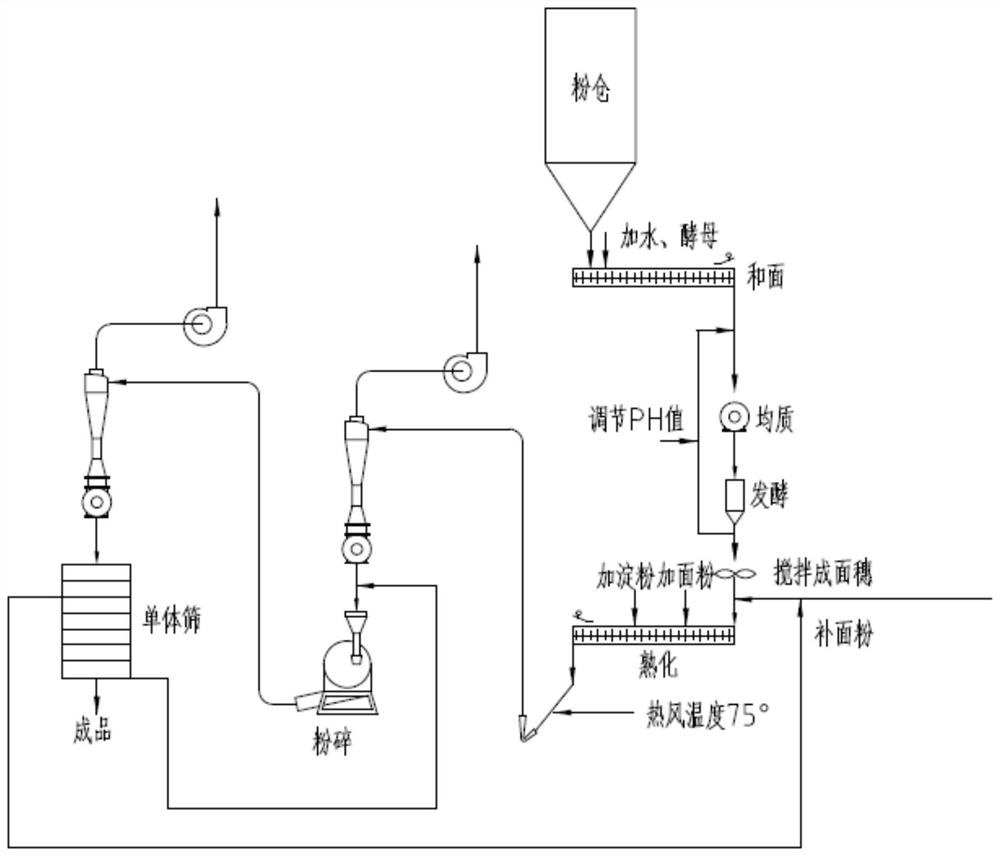

Industrial production process of fermented flour

A fermented flour, industrial production technology, applied in the direction of yeast-containing food ingredients, food heat treatment, food drying, etc., can solve the problems of unstable culture conditions, long fermentation time, extensive production process, etc., and achieve the effect of avoiding too long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take flour and water and add them to the dough mixer according to the mass ratio of 1:0.9, add yeast powder according to 0.3-0.4% of the total mass of flour and water, start the dough mixer, and mix at 25°C to form a batter.

[0034] (2) The batter is sent into the homogenizer, and at 25° C., 1400 rpm centrifugal stirring (transient treatment) to complete the homogenization, so that the batter forms a free suspension of flour in water.

[0035] (2) The homogenized batter is sent to a fermenter for 30 minutes of fermentation at a fermentation temperature of 25°C.

[0036] (3) Put flour in the flour mixer, start the mixer, 1400rpm centrifugal stirring, under this condition, the batter after fermentation is sent into the mixer, and the batter flowing in is thrown out simultaneously with the flour under high-speed stirring to form thin flour ears.

[0037] (4) The thin noodles are sent to the ripening machine, and the flour is added first for processing to form a small ...

Embodiment 2

[0041] (1) Take flour and water and add them to the dough mixer according to the mass ratio of 1:1, add yeast powder according to 0.3-0.4% of the total mass of flour and water, start the dough mixer, and mix at 25°C to form a batter.

[0042] (2) The batter is sent into the homogenizer, and at 25° C., 1500 rpm centrifugal stirring (transient treatment) to complete the homogenization, so that the batter forms a free suspension of flour in water.

[0043] (2) The homogenized batter is sent to a fermenter to ferment for 25 minutes at a fermentation temperature of 28°C.

[0044] (3) Flour is put into the flour mixer, start the mixer, 1200rpm centrifugal stirring, under this condition, the batter after fermentation is sent into the mixer, and the batter flowing in is thrown out simultaneously with the flour under high-speed stirring to form a thin noodle ear.

[0045] (4) The thin noodles are sent to the ripening machine, and the flour is added first for processing to form a small ...

Embodiment 3

[0049] (1) Take flour and water and add them to the dough mixer according to the mass ratio of 1:0.7, add yeast powder according to 0.3-0.4% of the total mass of flour and water, start the dough mixer, and mix at 25°C to form a batter.

[0050] (2) The batter is sent into the homogenizer, and at 30° C., 1500 rpm centrifugal stirring (transient treatment) to complete the homogenization, so that the batter forms a free suspension of flour in water.

[0051] (2) The homogenized batter is sent to a fermenter for 20 minutes of fermentation at a fermentation temperature of 30°C.

[0052] (3) Put flour in the flour mixer, start the mixer, 1500rpm centrifugal stirring, under this condition, the batter after fermentation is sent into the mixer, and the batter flowing in is thrown out simultaneously with the flour under high-speed stirring to form thin flour ears.

[0053] (4) The thin noodles are sent to the ripening machine, and the flour is added first for processing to form a small do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com