A vibration-scattering hot air drying device suitable for dehydration and drying of desulfurized gypsum powder

A desulfurization gypsum powder and hot air technology, which is applied in the directions of dry gas arrangement, dry cargo handling, and dry solid materials, etc., can solve the problems of gypsum heating, insufficient heating, crushing and uneven drying, and achieve the effect of avoiding waste and good collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

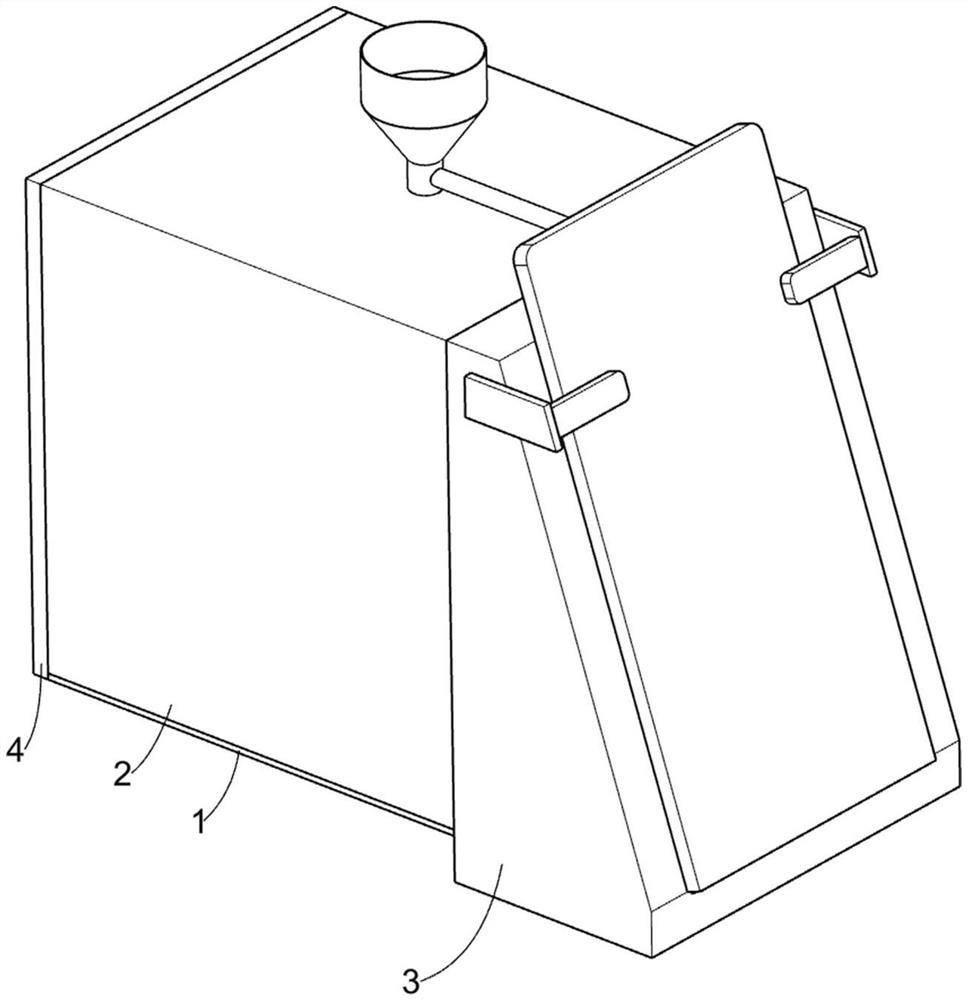

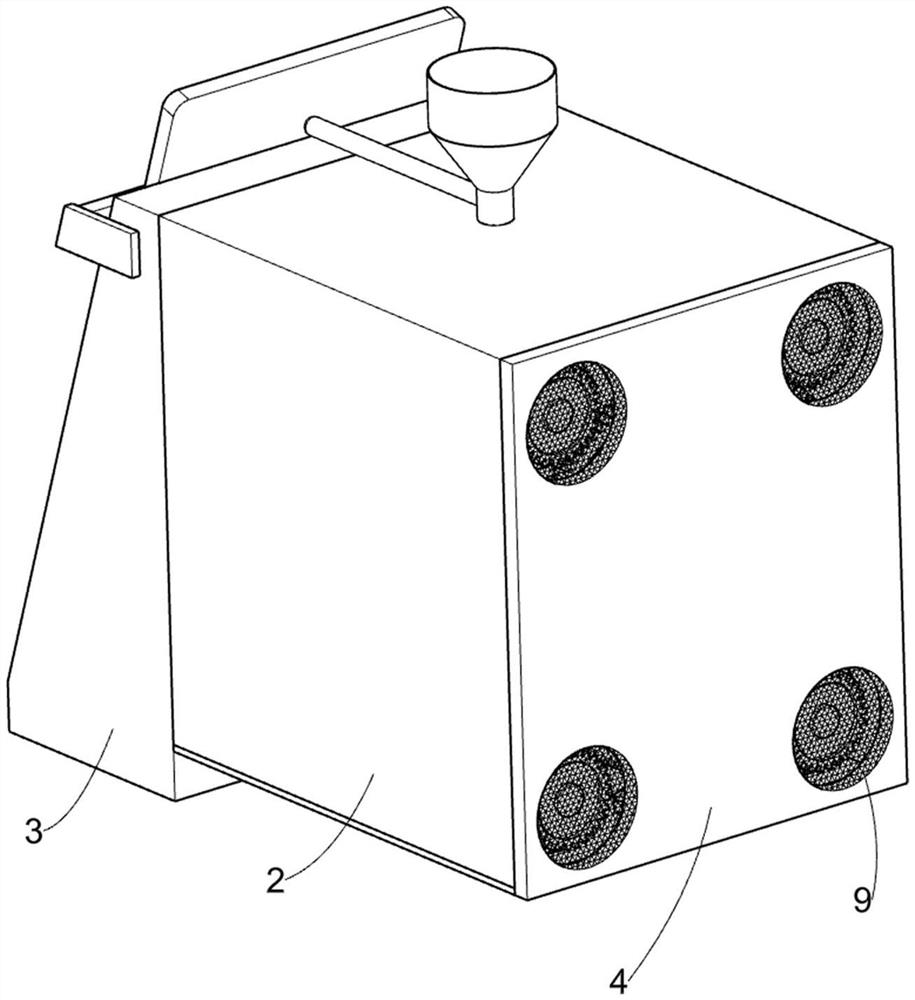

[0023] A vibration-scattering hot-air drying device suitable for dehydration and drying of desulfurized gypsum powder, combined with Figure 1-9 As shown, it includes a bottom plate 1, a U-shaped frame 2, an inclined surface guide frame 3, a rear opening cover plate 4, a desulfurized gypsum powder vibration and dispersion mechanism 5, a desulfurized gypsum powder replenishment mechanism 6, and a desulfurized gypsum powder high-temperature dehydration mechanism 7 and Dust shaking mechanism 8, U-shaped frame 2 is fixedly installed on the bottom plate 1, inclined surface guide frame 3 is fixedly installed on one side of the U-shaped frame 2 and the bottom plate 1 is connected, and the rear side opening cover plate 4 is fixedly installed on the U-shaped frame The other side of 2 is connected with the bottom plate 1, and four small round holes are opened on the rear side opening cover plate 4, and the desulfurization gypsum powder vibration and dispersion mechanism 5 is arranged on ...

Embodiment 2

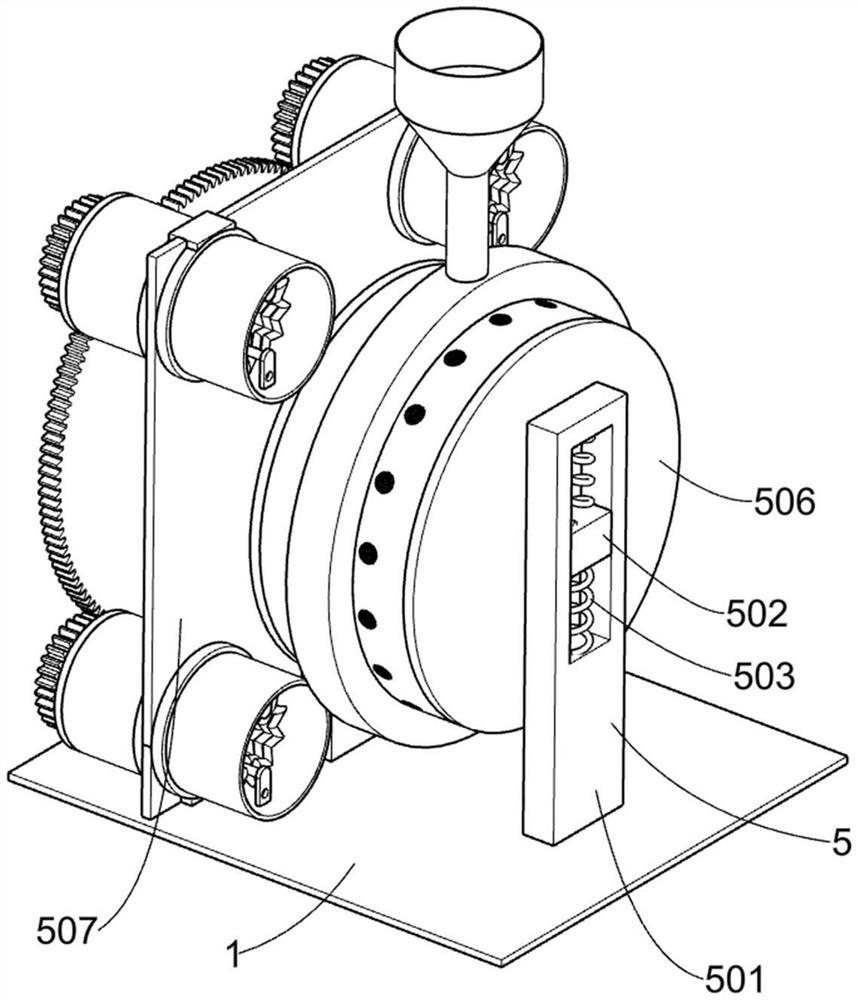

[0025] On the basis of Example 1, combined with Figure 1-9 As shown, the desulfurization gypsum powder vibration and dispersion mechanism 5 includes a guide plate 501, a movable block 502, a first compression spring 503, a connecting shaft 504, a centrifugal rotating rod 505, a vibration and dispersion frame 506, a partition plate 507, and a first drive shaft 508 , pulley 509, elastic retractable belt 5010, servo motor 5011, second drive shaft 5012 and small diameter bevel gear 5013, the guide plate 501 is fixedly installed on the bottom plate 1 and there is a chute on the guide plate 501, the guide plate 501 is vertically arranged And it is a cuboid, the square movable block 502 is slidably installed in the chute of the guide plate 501, a first compression spring 503 is installed between the guide plate 501 and the movable block 502, and the partition plate 507 is fixedly installed on the bottom plate 1 and is connected to the bottom plate 1. The inner side of the U-shaped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com