Inverted vacuum dehydration device after cleaning and sterilizing open ampoules

An ampoule bottle and vacuum technology, which is applied in the field of machinery, can solve the problems of low production efficiency, high production capital investment, and high breaking rate of open ampoule bottles, and achieves the effect of improving production efficiency and simple mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

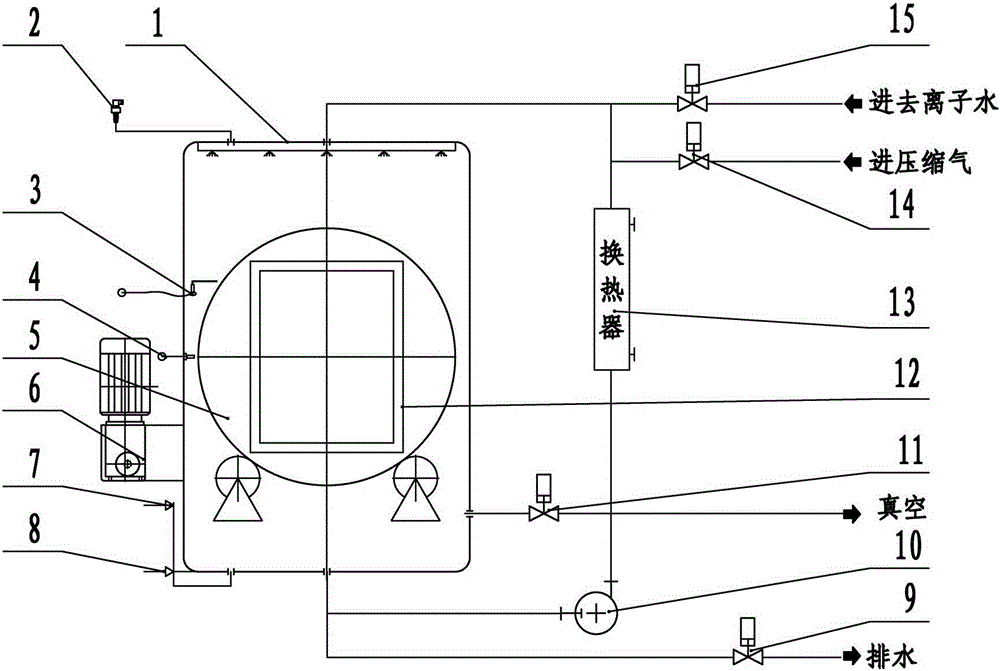

[0012] For the convenience of explanation, the following is combined with the figure 1 , the inverted vacuum water removal device after the cleaning and sterilization of the open ampoule bottle of the present invention is described in detail. It should be understood that the following examples are only used as an embodiment of the present invention, and are not intended to limit the present invention:

[0013] as attached figure 1 As shown in , an inverted vacuum dewatering device after cleaning and sterilizing an open ampoule bottle, the inverted vacuum dewatering device after cleaning and sterilizing an open ampoule bottle includes a sterilizing cabinet main body 1 and a sterilizing cabinet main body 1 The sterilizing vehicle 12 and the rolling cage 5 inside, the sterilizing vehicle 12 is fixed in the rolling cage 5, the outside of the main body 1 of the sterilizing cabinet is provided with a pressure sensor 2, a middle water level probe 7 and a lower The water level probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com