Separation equipment for preventing sludge blockage in sewage treatment

A technology for sewage treatment and separation equipment, which is applied in water/sludge/sewage treatment, sludge treatment, sustainable biological treatment, etc. It can solve the problem that the differential feed compression and sludge discharge cannot be realized, and the centrifugal separation effect cannot be guaranteed. , It is impossible to realize the problems of linkage vibration and water removal, so as to achieve the effect of improving the overall practicability, the overall structure is simple and stable, and the structure is simple and practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

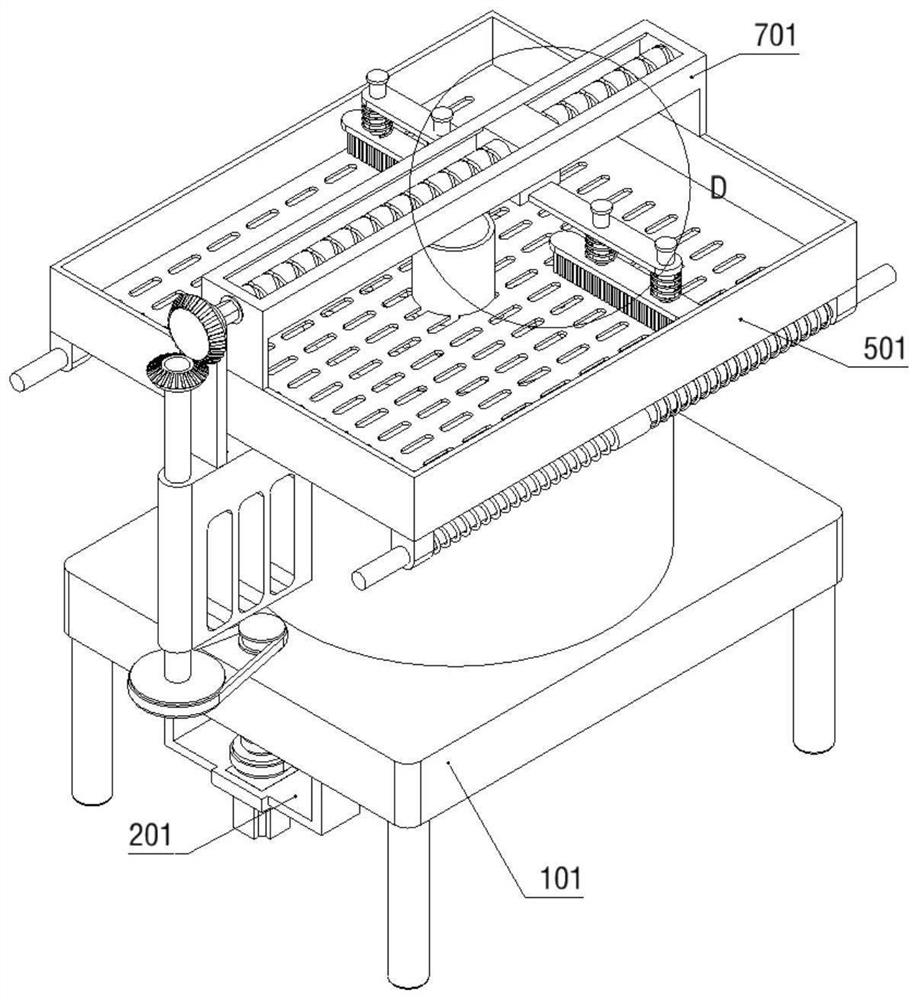

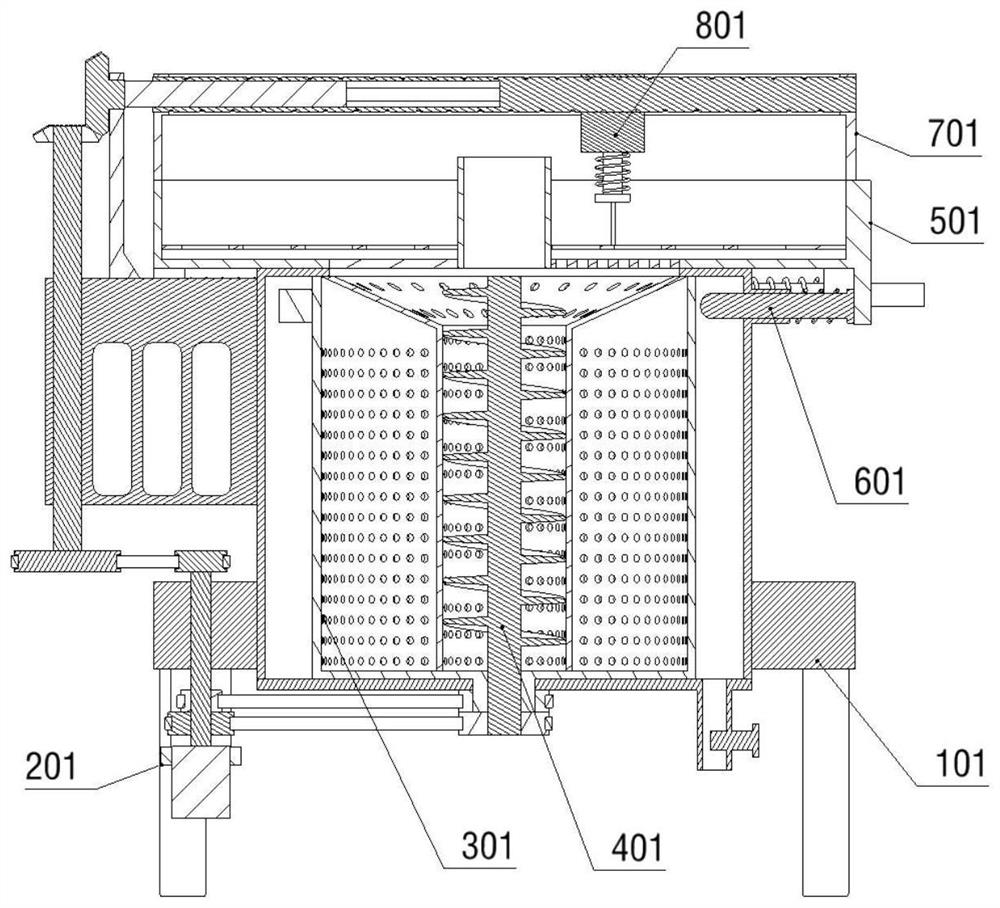

[0040] Please refer to Figure 1 to Figure 13 :

[0041] The invention proposes a separation device for preventing sludge clogging for sewage treatment, which includes an installation support part 1; a differential drive device 2 is fixedly connected to the installation support part 1; a terminal filter part 3 is rotatably connected to the installation support part 1; The conveying device 4 is installed on the part 3; the movable bearing part 5 is slidably connected to the installation support part 1; the extrusion linkage part 6 is slidably connected to the installation support part 1; The cleaning device 8 is installed on the sliding reciprocating drive part 7; the installation support part 1 includes: an installation support plate 101, a support leg 102, a protective installation cylinder 103, a water outlet pipe 104 and a rotating shaft frame 105. The bottom of the installation support plate 101 is fixedly connected with four A protective installation cylinder 103 is fixe...

Embodiment 2

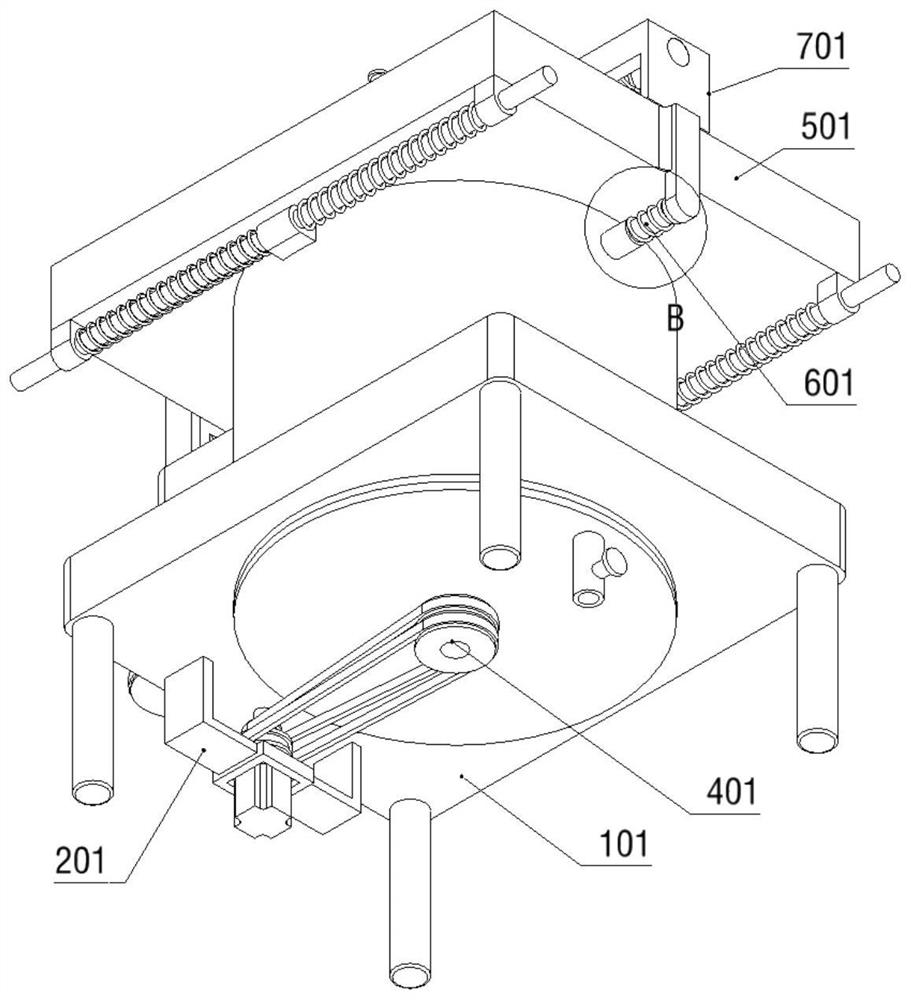

[0044] like Figure 8 to Figure 10 As shown, the conveying device 4 includes: a conveying auger 401 and a conveying pulley 402, the conveying auger 401 is rotatably connected to the centrifugal mesh cylinder 301; the bottom of the conveying auger 401 is fixedly connected with a conveying pulley 402, and the conveying pulley 402 passes through The belt drive is connected to the conveying drive pulley 203; the conveying device 4 also includes: a conveying isolation cylinder 403 and a collecting mesh ring 404, the conveying isolation cylinder 403 is fixedly connected inside the centrifugal mesh cylinder 301; the conveying isolation cylinder 403 is provided with filter holes; The isolation cylinder 403 is fixedly connected with a collection screen ring 404, and the collection screen ring 404 is provided with filter holes; the moving bearing part 5 includes: a moving box 501, a sliding drive shaft 5011, a return spring 502, a lower filter screen 503, and a collection isolation scree...

Embodiment 3

[0046] like Figure 11 to Figure 13 As shown, the sliding reciprocating drive part 7 includes: a sliding support 701, a reciprocating screw 702, a driving sliding shaft 703, a cleaning drive bevel gear 704 and a gear frame 7041, and the sliding support 701 is fixedly connected to the moving box 501; the sliding support A reciprocating screw 702 is rotatably connected to the reciprocating screw 701, and a hexagonal hole is formed on the reciprocating screw 702; the reciprocating screw 702 is provided with a bidirectional thread; the reciprocating screw 702 is slidably connected with a driving sliding shaft 703, and the driving sliding shaft 703 has a hexagonal structure; the driving sliding shaft 703 is fixedly connected with a cleaning and driving bevel gear 704; the cleaning and driving bevel gear 704 is engaged with the transmission bevel gear 108; 7041 is fixedly connected to the rotating shaft frame 105; the cleaning device 8 includes: a cleaning sliding frame 801, a mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com