Loading apparatus for chain cable tensile testing machine

A tensile testing machine and loading device technology, which is applied to measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of complex structure, high cost of loading devices, heavy total weight, etc., and reduce manufacturing costs. cost, improve work efficiency, prolong the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

[0030] This embodiment takes the loading device of a 12MN continuous semi-automatic anchor chain tensile testing machine as an example.

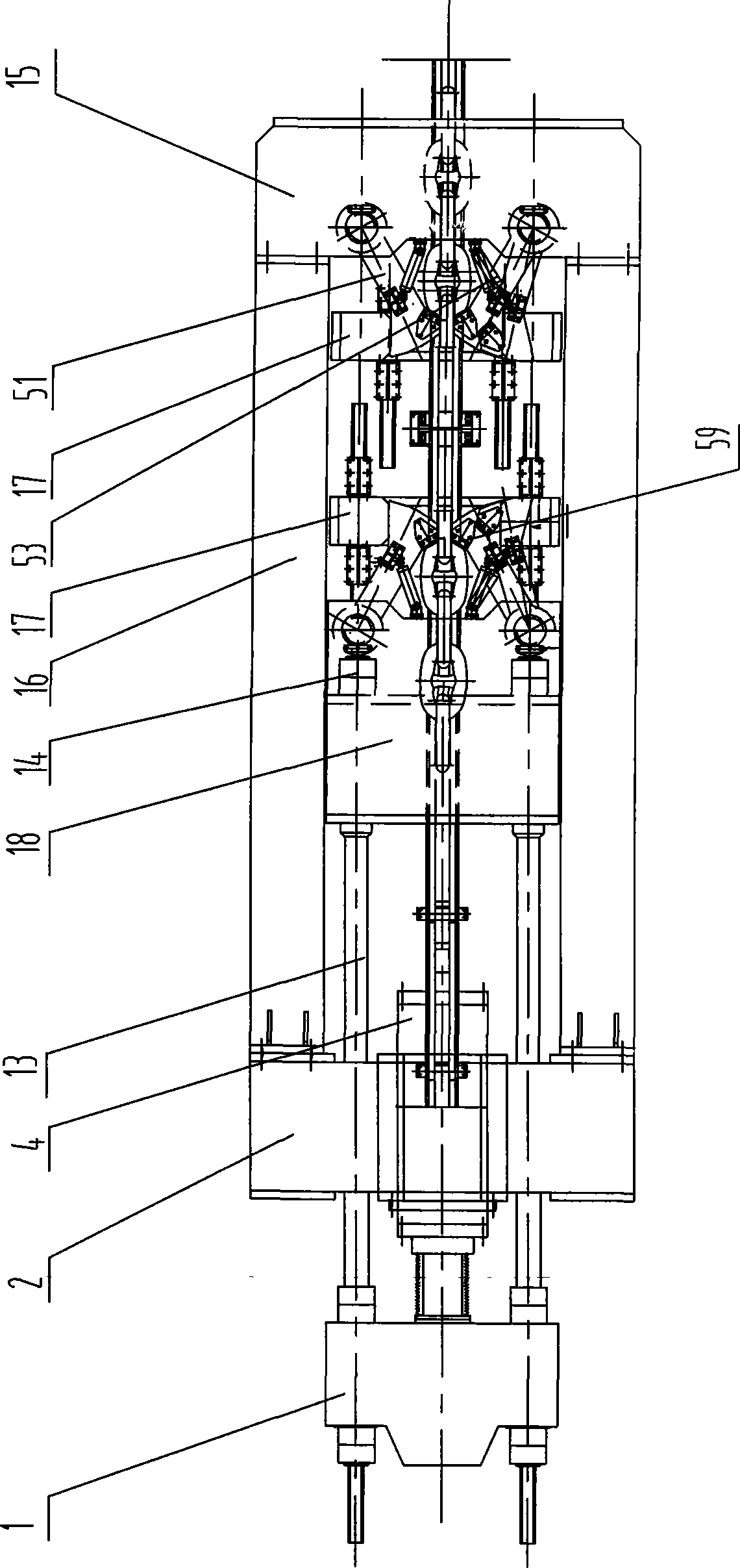

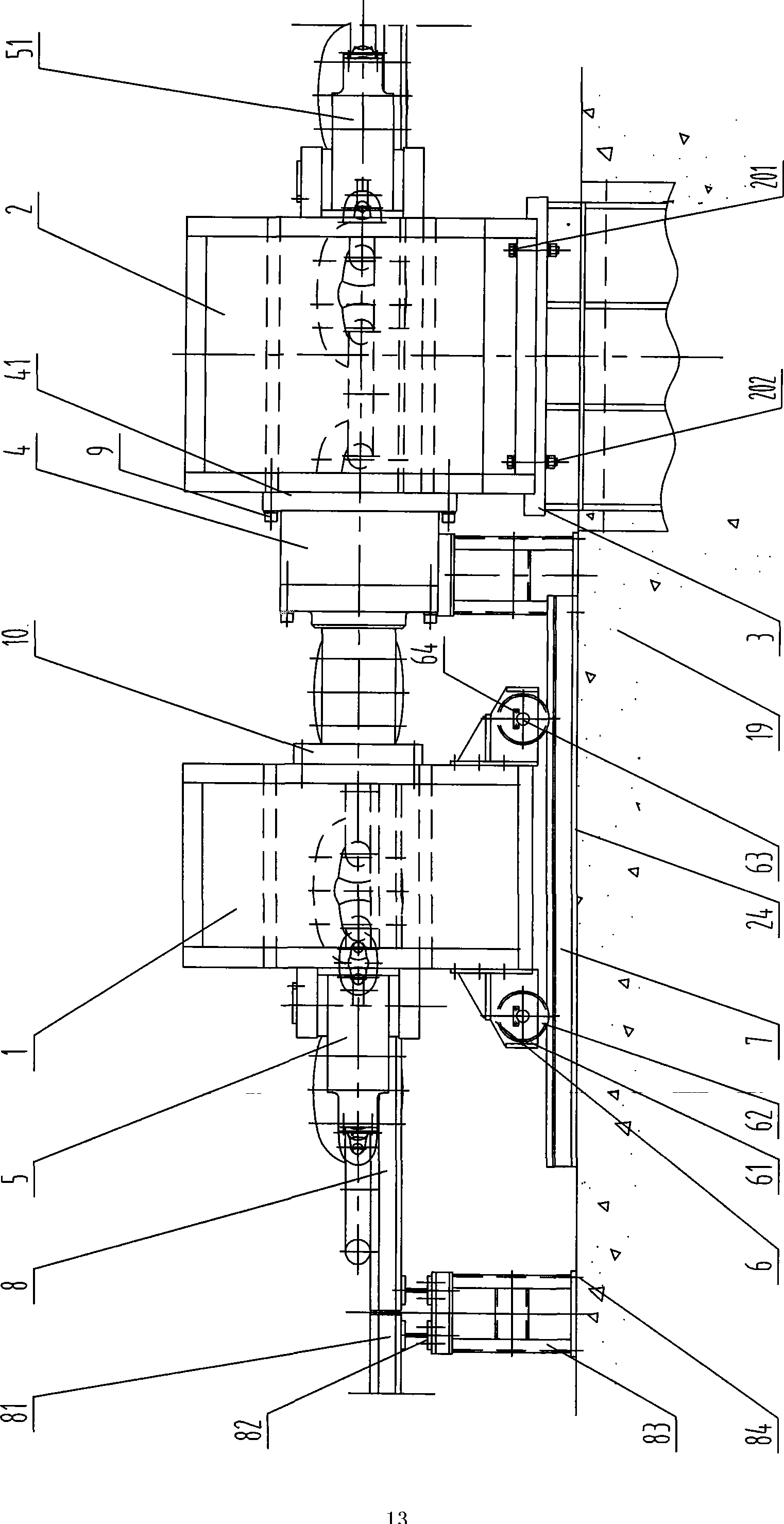

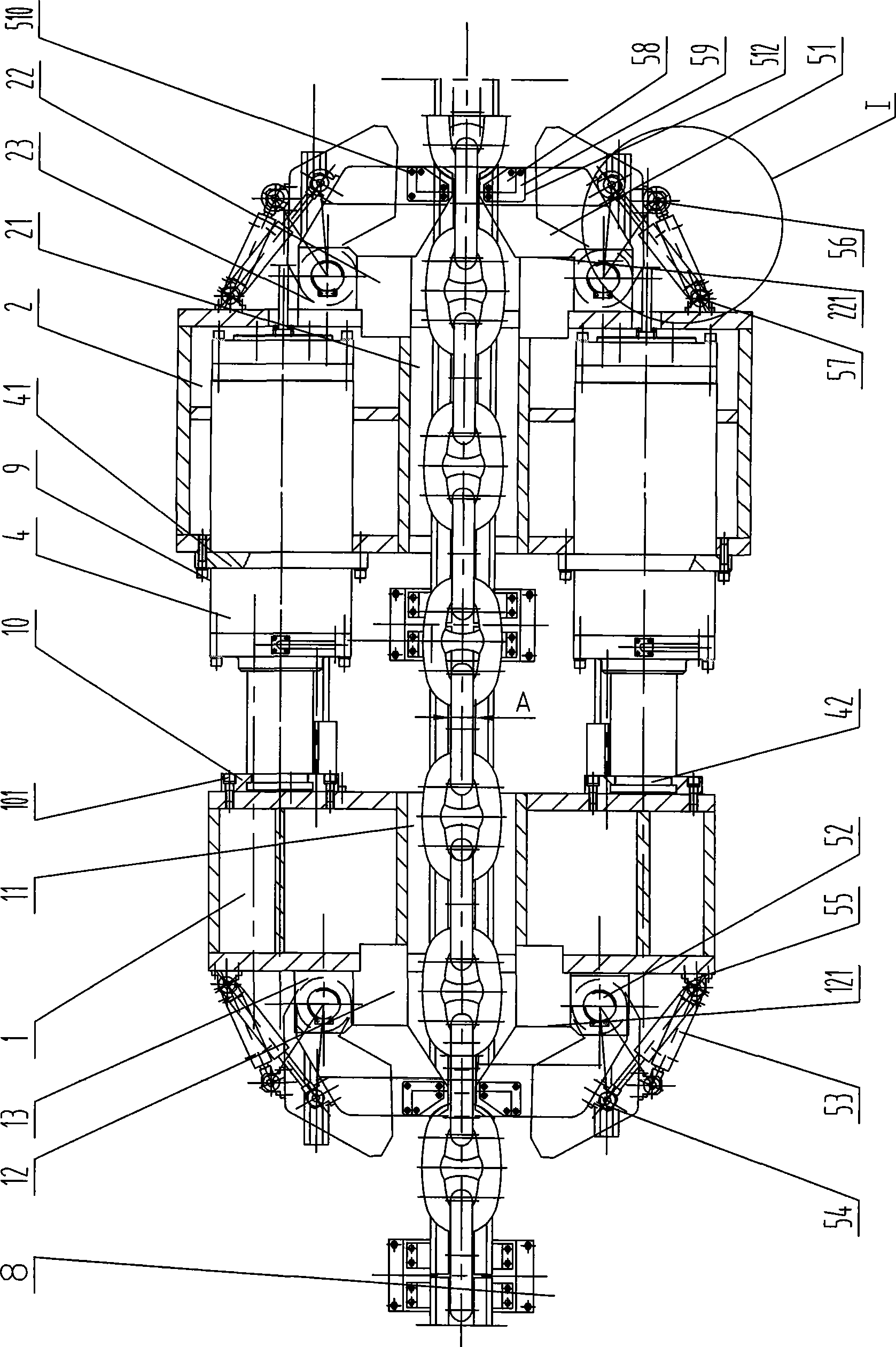

[0031] see figure 2 , image 3 and Figure 4, The present invention includes a moving beam 1, a fixed beam 2, a fixed beam base 3, a double loading cylinder 4, an anchor chain ring clamping device 5, a moving device 6, a track 7 and an anchor chain support rail device 8. The fixed beam base 3 is buried in the concrete foundation 19 , and the bottom surface of the fixed beam 2 and the top surface of the fixed beam base 3 are fixedly connected by bolts 201 and nuts 202 . Two loading cylinders 4 are symmetrically arranged in the fixed beam 2 along the length direction of the fixed beam 2, the mounting flange 41 of the loading cylinder 4 is fixedly connected with the front side of the fixed beam 2 by screws 9, and the piston rod head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com