Fastener and heat radiating device assembly using the same

A technology for heat sinks and fasteners, applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc. Problems such as adverse consequences of heat dissipation to achieve the effect of ensuring the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

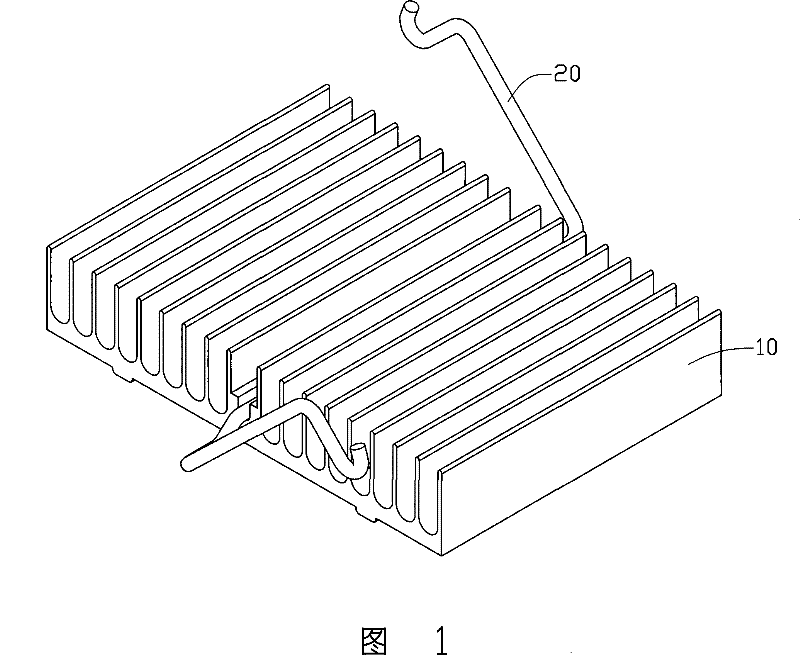

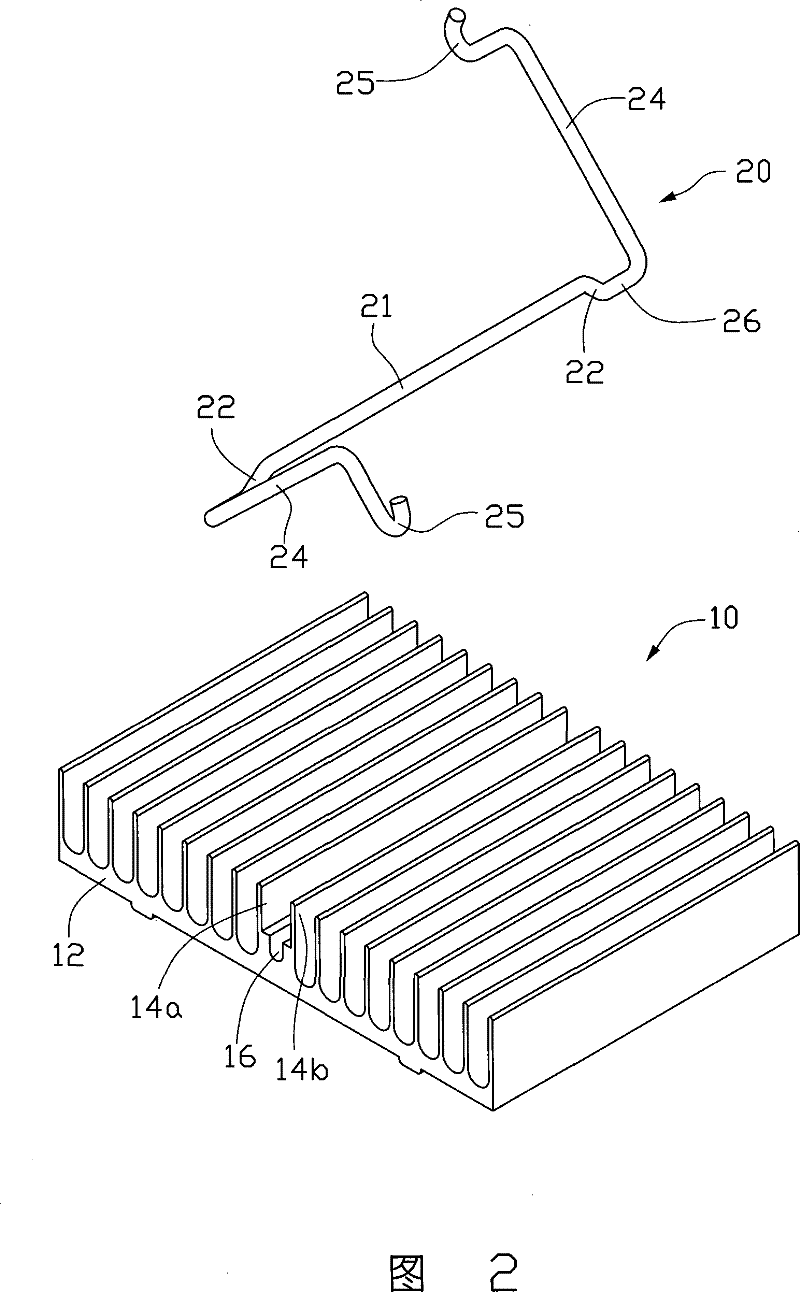

[0011] figure 1 and figure 2 Disclosed is a heat sink assembly in a preferred embodiment of the present invention, which is used to dissipate the heat released by electronic components (not shown) mounted on a circuit board (not shown), the heat sink assembly includes a heat sink 10 and A fastener 20 is used to fix the heat sink 10 to the circuit board and fit the electronic components.

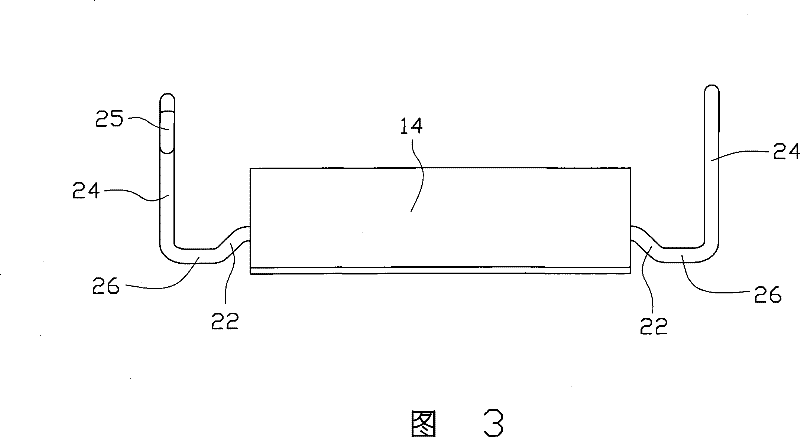

[0012] The heat sink 10 is integrally made of high thermal conductivity materials such as copper, aluminum or alloys thereof. The heat sink 10 includes a substantially rectangular bottom plate 12 and a plurality of cooling fins 14 vertically extending upward from the bottom plate 12 . The heat dissipation fins 14 are spaced apart from each other and parallel to a pair of shorter sides of the bottom plate 12 , and a flow channel (not shown) for air flow is formed between each two adjacent heat dissipation fins 14 . A straight groove 16 is formed between two adjacent cooling fins 14a, 14b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com