Filling apparatus, machine and method for filling of casings, particularly sausage casings

A filling device and casing technology, which is applied in sausage enema machines, sausage making, slaughtering, etc., can solve the problems of time-consuming increase, cycle frequency influence, cost increase, etc., and achieve the effect of reducing the number of parts, reducing downtime, and avoiding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

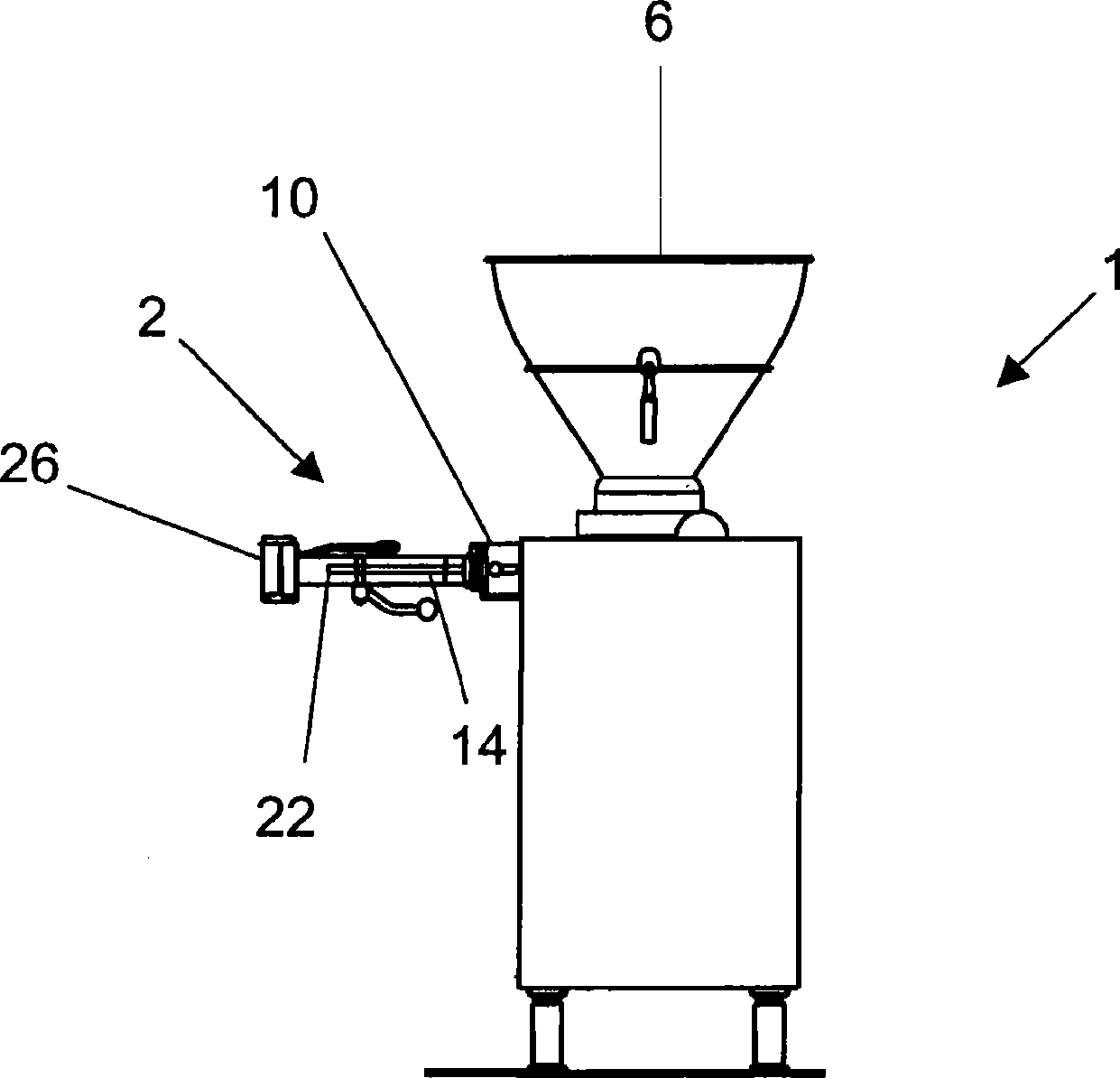

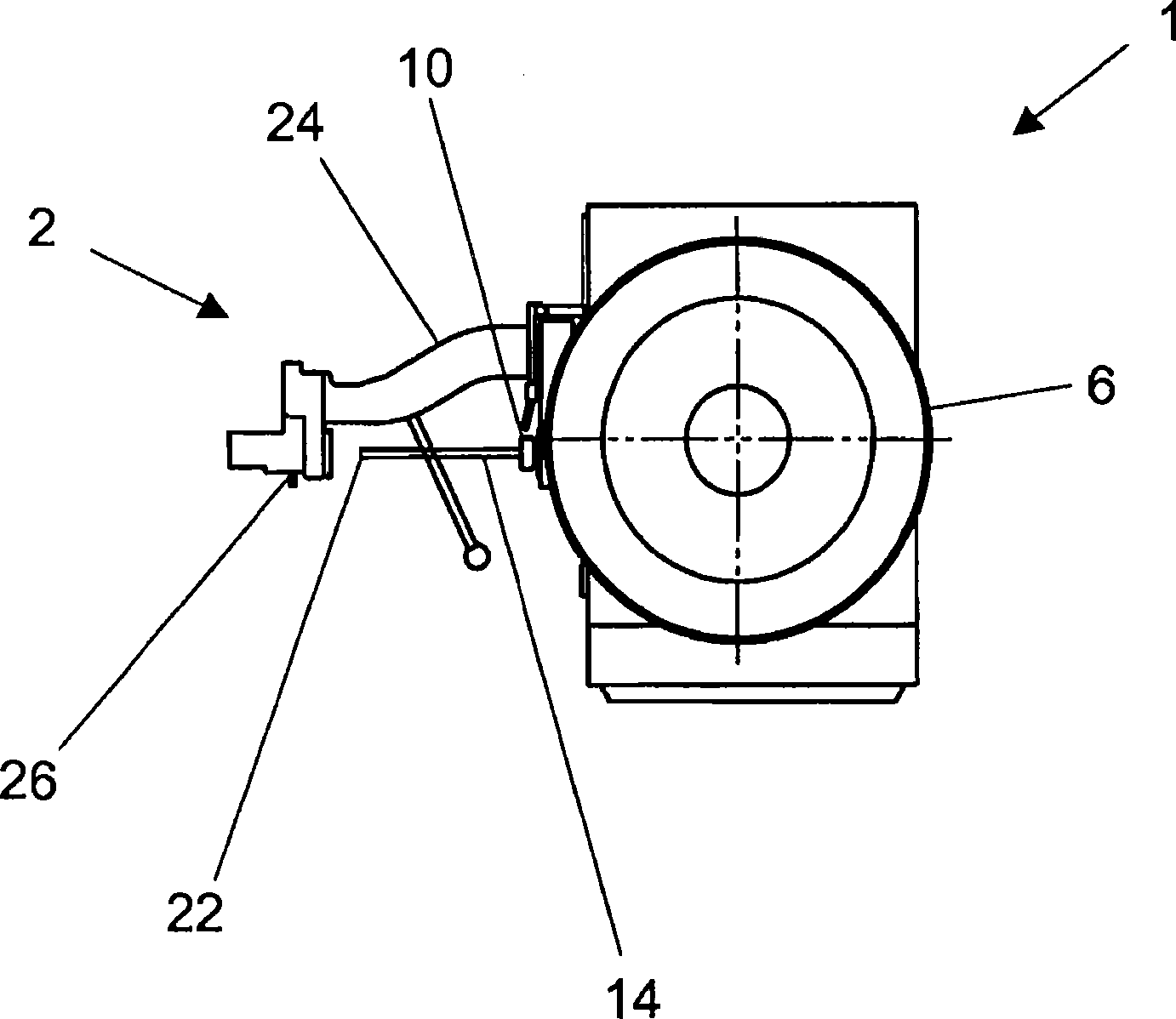

[0021] figure 1 Shown is a machine 1 for filling casings, in particular sausage casings, which is equipped with a filling device 2 according to the invention. The machine 1 also comprises a supply container 6 formed as a filling funnel, conveying means (not shown) for conveying pasty material, in particular sausage meat, a drive unit, a control regulation unit and operating means for operating the machine 1 . The sausage meat placed in the supply container 6 is supplied to the filling device 2 via a conveying device, in this way the sausage casings (not shown) to be filled can be filled with sausage meat or other pasty material.

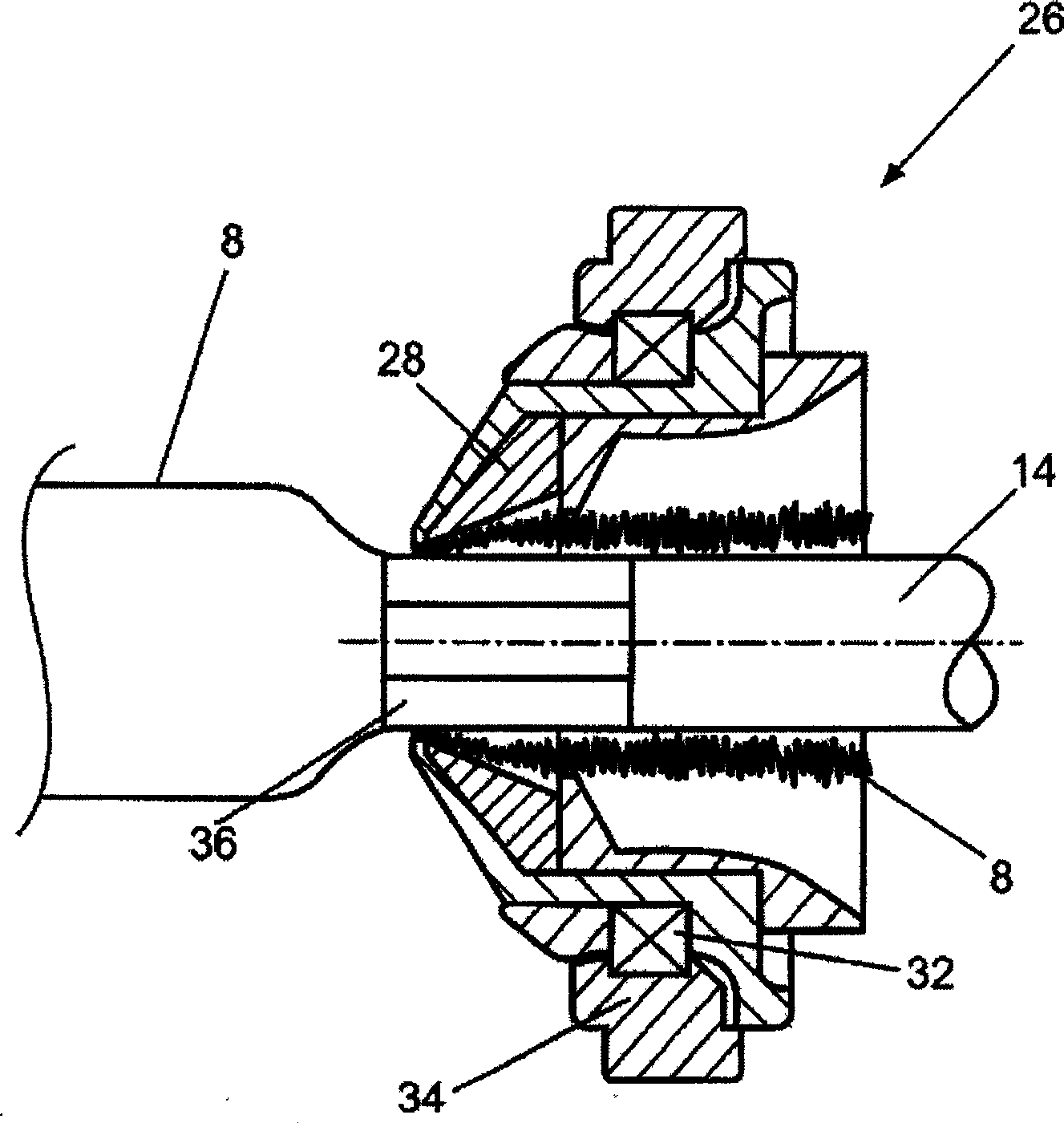

[0022] The casings (especially sausage casings 8) that need to be filled are set on the hollow filling tube 14 ( image 3 ), the filling tube 14 is driven to rotate by the drive transmission member 10. It can also be seen that there is a brake ring 28 ( image 3 ) The casing brake 26 is mounted coaxially with the axis of rotation of the filling tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com