Gas-liquid separator based on porous media board

A gas-liquid separation device and porous media technology, which are applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of unstable microporous filtration separation work, narrow separation load range, and poor separation effect, etc. To achieve the effect of simple structure, good cost control and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0069] 1) Basic composition of the device

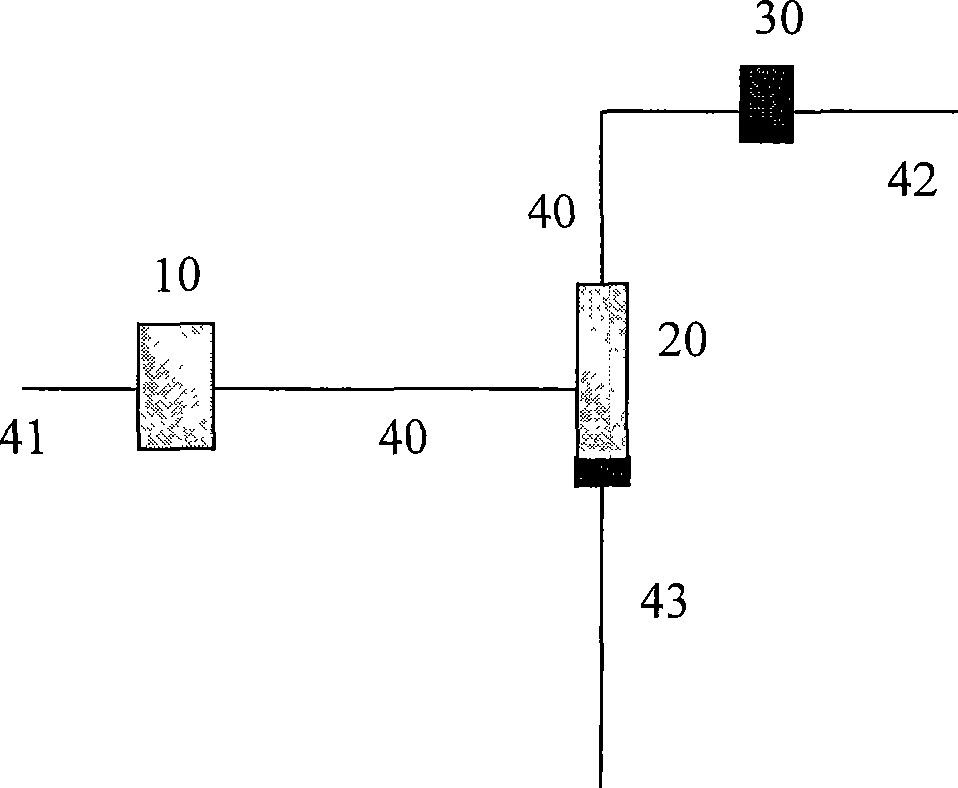

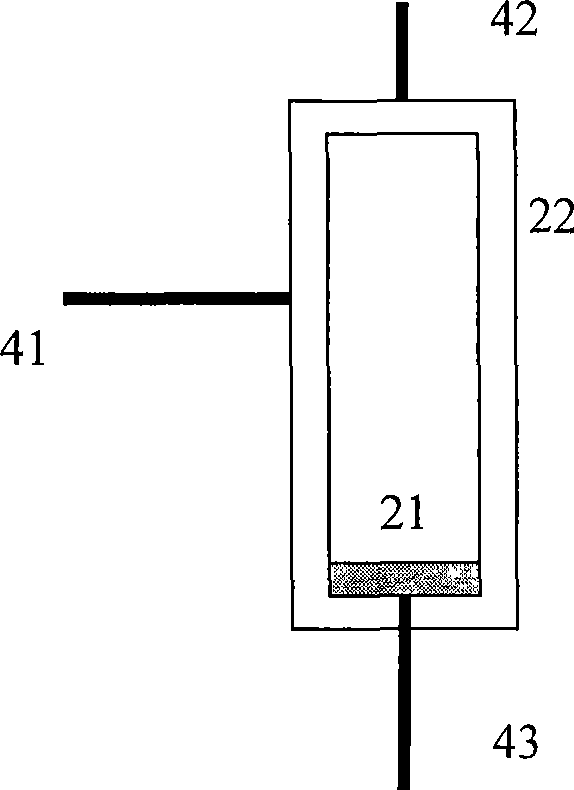

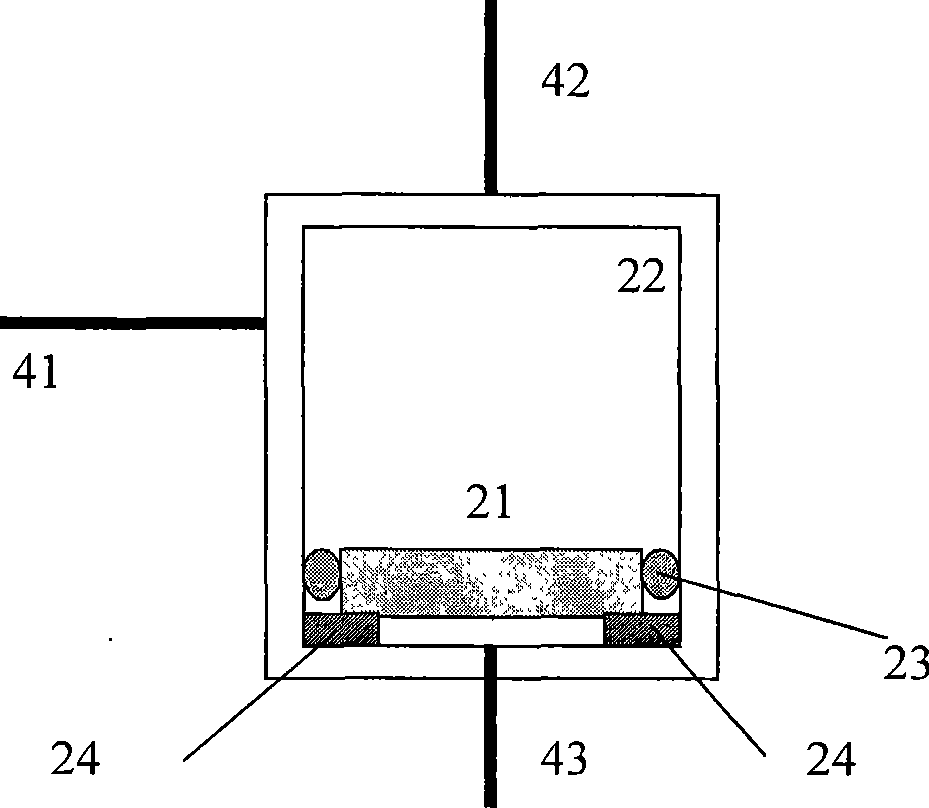

[0070] The device is composed of a filter 10, a gas-liquid separation container 20, a pressure regulating valve 30, and a pipeline 40; the pressure of the liquid passing through the gas-liquid separation container 20 is increased through the pressure regulating valve 30, thereby promoting the liquid in the gas-liquid mixed fluid to quickly The gas passes through the porous medium plate 21 at the lower part of the gas-liquid separation container, and the gas is discharged from the gas-liquid separation container 20 through the pressure regulating valve 30, so as to realize the gas-liquid separation of the gas-liquid mixed fluid.

[0071] A gas-liquid separation device based on a porous medium plate, the relationship between the components is: the gas-liquid separation container 20 is connected to the filter 10 and the pressure regulating valve 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com